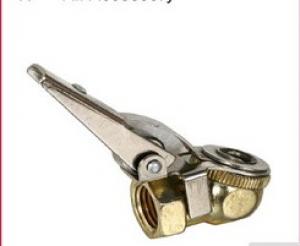

AIR FILTER BFC-4000 3

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Description:

· Air source treatment unit includes filter regulator and lubricator, It is in standard modular design and can freely separate and combine.

· Filter adopts novel vane design with high division efficiency and differential pressure discharge device. It can discharge water automatically.

· Regulator valve adopts balanced inlet structure with the advantages of stable pressure, high precision, and quick reaction.

· Lubricator is an element that can provide good lubrication for pneumatic system, with novel structure and easy adjustment of oil drip.

AIRTAC Air Filter Combination AFC2000 FR.L With Pressue Gauge

BFC2000 Two-point Combination Filter&Regulator Lubricator Air Units

BFC 3000 air combination filter regulator lubricator pressure regulator pneumatic component air unit air compressor

1/2'' BFC4000 Adjustable Pressure Air Source Treatment Unit

Air Source Treatment Air Filter Pneumatic Regulator Lubricator 0.5-9.0Kgf/cm2

- Q: Which is good between pneumatic tools and power tools?

- 4. the pneumatic system has a strong adaptability to the environment. It can work reliably in a wide temperature range, humid and dusty environment, with a slight leakage, no pollution to the environment, no fire and explosion hazards, and safe use5., simple structure, convenient maintenance and low cost6. long life of pneumatic components7. pneumatic actuators of the hydraulic output than small, fast, strong adaptability, can exercise in the flammable, explosive, heavy, damp, the impact of the harsh environment, no environmental pollution, long service life, simple structure, easy maintenance, low price.

- Q: Will the gas in the gas path corrode the pneumatic components after passing through the oil sprayer?

- The operating principle is that the atomizing oil is lubricated with high pressure air to the pneumatic equipment, and is not corrosive. Although the pneumatic solenoid valve or cylinder is no need to add lubrication. But friction products increase the service life by adding lubricating oil.Gas atomizer does not recommend adding common quality oil. It is recommended to use turbine No. 1 atomizer special oil.

- Q: Graphical symbols for pneumatic componentsThis is a manual valve on the Oh!

- This is the most common three bit four pass self-locking positioning manual reversing valve, but it is obviously wrong with drawing

- Q: Where are the industry standards for pneumatic components?

- GB/T 786.1 - 1993 (2001) hydraulic and pneumatic graphic symbolsISO 1219-1:19912, GB/T 2346 - 2003 fluid transmission system and components nominal pressure seriesISO, 2944:2000, MOD

- Q: I've checked PT teeth, NPT teeth and G teeth. I'd like to know which standard teeth we use on our cylinders, fast couplings and other components. Thank you

- The G is 55 degree tooth angle straight thread, and the NPT is 60 degree tooth angle, vertebral canal thread. What brands and cylinders do you use? What specifications do you want to see?.

- Q: How does the pneumatic valve change the AC to direct current?

- Two. Comparison of pneumatic control valve and hydraulic valve(I) the energy used is differentPneumatic components and devices can use the air compressor station centralized gas supply method, according to the use requirements and control points to adjust the working pressure of each reducing valve. The hydraulic valve is provided with a return line to facilitate the collection of the hydraulic oil used by the tank. The pneumatic control valve can direct the compressed air to the atmosphere through the exhaust port.(two) the requirement of leakage is differentThe hydraulic valve is strict with the outward leakage, but a small leak inside the component is permissible. For pneumatic control valves, in addition to the clearance seal valve, in principle, does not allow internal leakage. The internal leakage of pneumatic valves causes the risk of accidents.For pneumatic pipes, a little leakage is allowed, and the leakage of the hydraulic pipe will cause pressure drop and pollution to the environment.

- Q: What are the common pneumatic components?

- Two 、 triple filtration, cylinder, trachea, trachea joint, solenoid valve, air control valve, foot valve, hand valve, buffer, throttle valve, voltage regulator

- Q: What are the special advantages of the pneumatic device of a vibrating screen?

- 4 、 high reliability and long service life. Electrical components of the effective action of about a million times, while the general electromagnetic valve life of more than 30 million times, and some good quality valve more than 200 million times.

- Q: What are the components of a cylinder in a pneumatic system?

- The act or function of performing pneumatic system designs.

- Q: What are the parts of a pneumatic system?

- Pneumatic system source contains a number of Wuxi smart air source processor such as auxiliary components; pneumatic control part contains a variety of Wuxi smart precision valve, solenoid valve, cylinder and so on, which is used for flow, pressure and direction control of the working medium; implementation part contains a cylinder or a motor is started, according to the actual requirements of their choice

Send your message to us

AIR FILTER BFC-4000 3

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords