AIR FILTER BFC-4000 3/8

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Description:

· Air source treatment unit includes filter regulator and lubricator, It is in standard modular design and can freely separate and combine.

· Filter adopts novel vane design with high division efficiency and differential pressure discharge device. It can discharge water automatically.

· Regulator valve adopts balanced inlet structure with the advantages of stable pressure, high precision, and quick reaction.

· Lubricator is an element that can provide good lubrication for pneumatic system, with novel structure and easy adjustment of oil drip.

AIRTAC Air Filter Combination AFC2000 FR.L With Pressue Gauge

BFC2000 Two-point Combination Filter&Regulator Lubricator Air Units

BFC 3000 air combination filter regulator lubricator pressure regulator pneumatic component air unit air compressor

1/2'' BFC4000 Adjustable Pressure Air Source Treatment Unit

Air Source Treatment Air Filter Pneumatic Regulator Lubricator 0.5-9.0Kgf/cm2

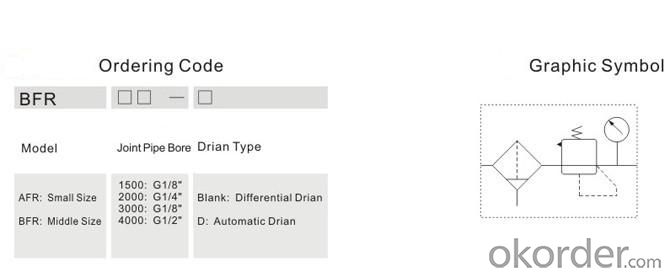

Ordering code:

Specification:

We manufacture all important parts by ourself to insure the quality, such as filter core. Outsourcing parts were selected and tested very strictly. Auto Drain can be selected.

- Q: What is the oil in the cylinder in the pneumatic original?

- Designed to make its sliding parts smooth and durable. Its lubricant oil is: turbine oil No. 1 (ISO VG32), very thin viscosity of about 7E degrees, mechanical lubricants, (equivalent to sewing machine oil). The oil mist of this kind of oil can be projected into the pipeline about 2M or so.

- Q: To pneumatic three components refueling, I would like to ask pneumatic three components should use what lubricating oil?. Thank you

- The viscosity, composition requirements are relatively high. Generally recommended ISO VG32 turbine oil (commonly known as turbine oil). Fog and lubrication is the best.

- Q: Will the gas in the gas path corrode the pneumatic components after passing through the oil sprayer?

- The oil in the fog is usually added with turbine No. 1, which is a special oil for pneumatic system.

- Q: Pneumatic components, three bit, five - way, can you explain?

- Five way: solenoid valve has 5 vents (usually 1 gas supply port P, 2 use mouth A, B, 2 exhaust port EA, EB)Above! A mouthful, slowly look at yourself

- Q: What is the gas in the two pneumatic combination?

- Pneumatic two piece is a filter, decompression, oil mist, the compressed air purification for the integration of two devices. The oil in the oil mist filler is: turbine oil No. 1, (International Brand: ISO, VG32), which has a very thin viscosity of about 7E degrees, lubricating oil (equivalent to 5E ~7E degrees of sewing machine oil)

- Q: Main points of type selection of pneumatic control valve

- Pneumatic control valve refers to the pneumatic system to control the flow of air pressure, flow and flow direction, and to ensure that pneumatic actuators or institutions work properly all kinds of pneumatic components. Pneumatic control valve structure can be broken down into the valve body (including the valve seat and valve hole, etc.) and valve heart two parts, according to the relative location of the two, there are normally closed and normally open two. Valve from the structure can be divided into: cut-off type, slide column and slide valve type three valves.

- Q: A brief description of pneumatic three element and its function

- I am glad to answer for you. Hope to give me 20 points pneumatic three element and its function is composed of water separator, air filter, pressure regulating valve and mist sprayer. The function is: water separating gas filter for filtering the compressed air in the water and impurity particles; the pressure regulating valve is used to adjust the pressure of the size, can according to your own needs to adjust; the oil mist is used to hold some of the more dilute lubricating oil, when a little oil will take the air into the cup. Play the role of lubrication and cooling to tools.

- Q: Pneumatic components generally used in what industry?

- Such as cylinders, pneumatic motors, steam engines, etc.. Pneumatic components are a form of power transmission, as well as an energy conversion device that uses gas pressure to transmit energy.

- Q: Pneumatic components, those equipment needs to be used, specific points. Additional reward

- Personally, I think it's available on the device. This mainly depends on the design concept of the designer.

- Q: Why is there any white thing on the outer thread of the pneumatic element PC?

- The raw material belt is a kind of auxiliary material commonly used in the plumbing and heating installation. It is used to connect the pipe fittings and enhance the tightness of the pipe connection. Raw materials with chemical name is PTFE, HVAC and water supply and drainage in the widespread use of ordinary white Teflon tape, and natural gas pipelines also have a special Teflon tape, in fact, the main raw material for PTFE, but some process. The raw meal band is a novel and ideal sealing material. Because of its non-toxic, tasteless, excellent sealing, insulation and corrosion resistance, it has been widely used in water treatment, natural gas, chemical, plastics, electronic engineering and other fields

Send your message to us

AIR FILTER BFC-4000 3/8

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords