Aluminum Construction Profiles - AA1050 Mill-Finished Aluminum Coils C.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

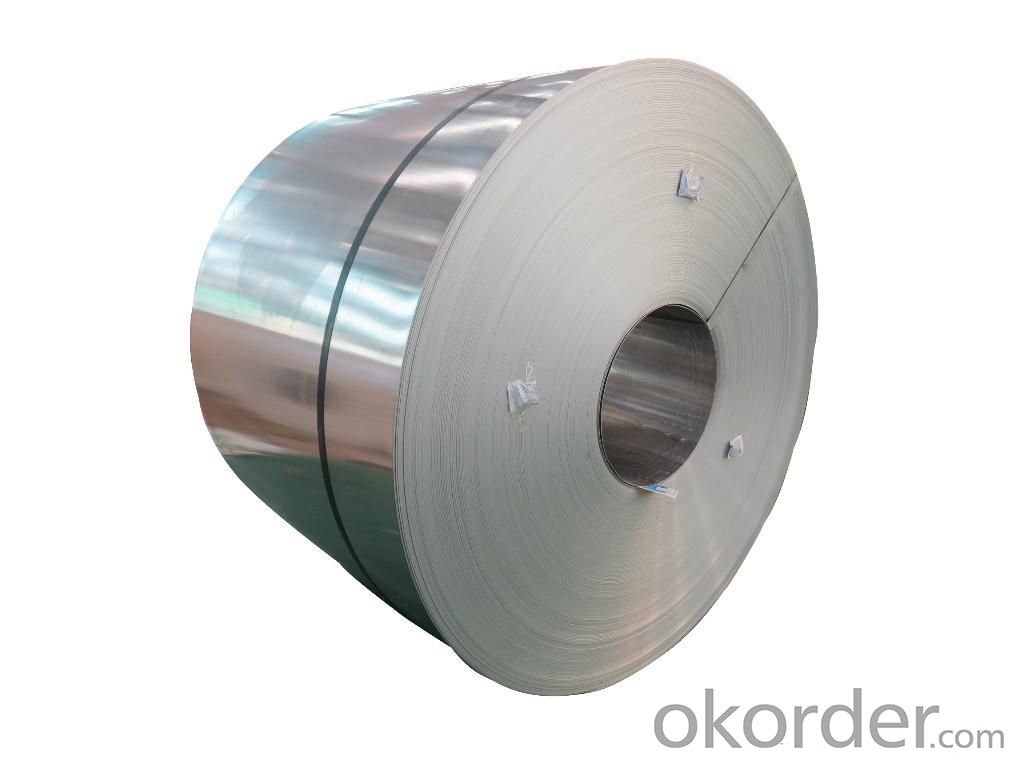

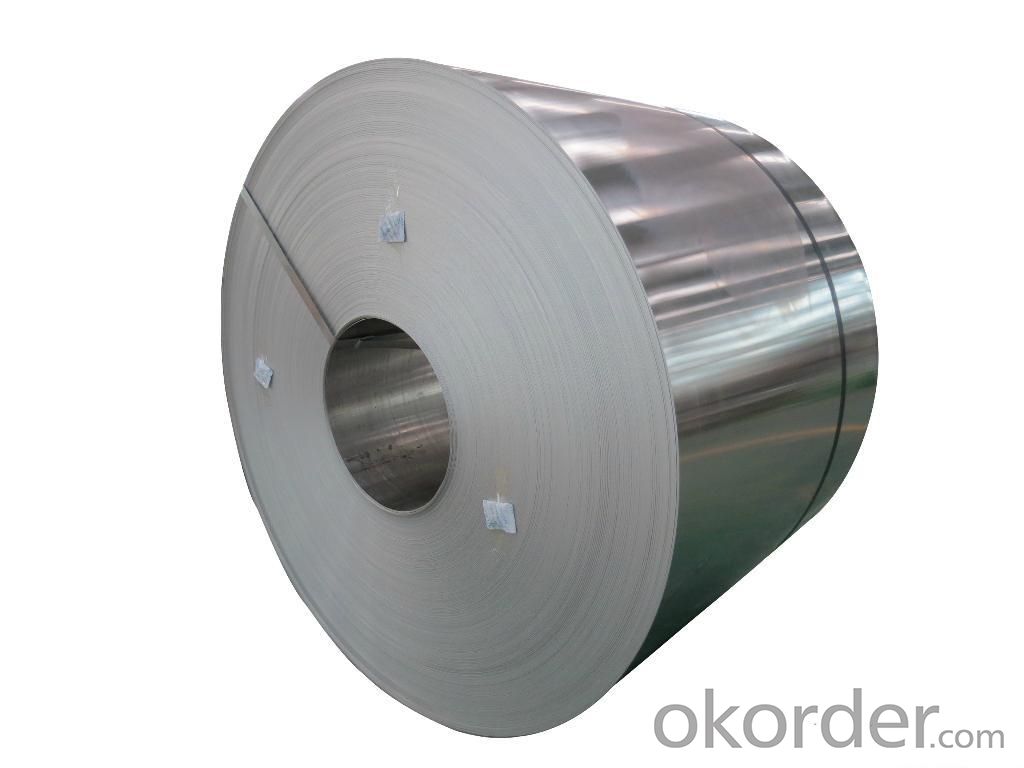

1.Structure of AA1050 Mill-Finished Aluminum Coils C.C Quality Used for Construction Description

AA1050 Mill-Finished Aluminum Coils C.C Quality Used for Construction has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

AA1050 Mill-Finished Aluminum Coils C.C Quality Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of AA1050 Mill-Finished Aluminum Coils C.C Quality Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

3.AA1050 Mill-Finished Aluminum Coils C.C Quality Used for Construction Images

4.AA1050 Mill-Finished Aluminum Coils C.C Quality Used for Construction Specification

Alloy | AA1050 |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA1050 Mill-Finished Aluminum Coils C.C Quality Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA1050 Mill-Finished Aluminum Coils C.C Quality Used for Construction.

B.When will you deliver the products?

It will be delivered within 35 days after receiving original L/C or advanced payment.

- Q: How do you install aluminum profiles?

- Follow these instructions for installing aluminum profiles: 1. Begin by measuring and cutting the profiles to the desired length using a saw equipped with a fine-tooth blade. It is essential to wear safety goggles and gloves during the cutting process. 2. Prior to installation, ensure the surface where the profiles will be placed is thoroughly cleaned. Remove any dirt, dust, or debris that could interfere with the installation. 3. Apply adhesive or silicone sealant to the back of the profile to securely attach it to the surface and create a watertight seal. 4. Position the profile on the surface and firmly press it down to guarantee proper adhesion. Utilize a level to ensure it is straight and correctly aligned. 5. If needed, utilize screws or fasteners to further secure the profile to the surface. Pre-drill pilot holes to prevent any cracking of the aluminum. 6. Repeat this process for each profile, leaving a small gap between them to account for expansion and contraction. 7. Once all profiles are installed, remove any excess adhesive or sealant. Use a damp cloth or sponge to wipe away any residue. 8. Allow the profiles to fully cure according to the manufacturer's instructions before applying any additional finishes or utilizing the area. Always consult the manufacturer's instructions for specific installation guidelines and recommendations.

- Q: This question asks if there are any health hazards linked to handling aluminum profiles.

- <p>Generally, working with aluminum profiles does not pose significant health risks. Aluminum is a lightweight, corrosion-resistant metal that is widely used in various industries. However, inhalation of aluminum dust or fumes over long periods may cause respiratory issues. Workers should use appropriate personal protective equipment (PPE) such as masks and gloves to minimize exposure. Additionally, aluminum can cause skin irritation in some individuals, so skin contact should be avoided. It's important to follow safety guidelines and maintain good hygiene practices when working with aluminum profiles.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing aluminum profiles within the construction industry.

- <p>Aluminum profiles offer several advantages in construction, including high strength-to-weight ratio, corrosion resistance, and ease of fabrication. They are lightweight, which reduces the load on structures and facilitates easier installation. Their resistance to corrosion means they require less maintenance and have a longer lifespan compared to steel. Additionally, aluminum profiles can be easily cut, bent, and joined, making them versatile for various applications. However, they have some disadvantages, such as lower thermal conductivity, which can be a concern in temperature-sensitive environments. They are also more expensive than some traditional materials like steel. Lastly, aluminum profiles can dent or deform under heavy loads, which may limit their use in certain structural applications.</p>

- Q: What unique considerations or criteria must be met when installing aluminum profiles to ensure they are correctly installed?

- <p>Yes, there are special requirements for installing aluminum profiles correctly. These include ensuring the profiles are of the correct size and specifications for the intended application, proper alignment to maintain structural integrity, and secure fastening to prevent movement or damage. Additionally, it's crucial to follow the manufacturer's guidelines for installation, which may include specific torque settings for screws or bolts, and to consider environmental factors such as temperature and humidity that could affect the profile's performance over time. Proper installation also involves checking for any damage or defects in the profiles before installation and ensuring that all components are compatible with each other.</p>

- Q: Are aluminum profiles suitable for use in food processing environments?

- Aluminum profiles are well-suited for application in food processing environments. The food industry widely utilizes aluminum due to its exceptional properties. Its lightweight, durable, and corrosion-resistant nature makes it an ideal material for use in food processing, where cleanliness and hygiene are paramount. Cleaning and sanitizing aluminum profiles is a breeze, which is crucial for preventing contamination and ensuring food safety. Their smooth and non-porous surface inhibits bacterial growth and simplifies maintenance. Moreover, aluminum boasts excellent thermal conductivity, enabling efficient heat transfer and temperature control during food processing. This characteristic proves particularly valuable in food packaging, cooking, and chilling applications. In addition to its physical attributes, aluminum is non-toxic and does not react with food or beverages. As an inert material, it does not release any harmful substances that could contaminate the processed food. Overall, aluminum profiles are a reliable and suitable choice for food processing environments. They meet the industry's stringent requirements for hygiene, durability, and safety, making them a popular option in the food processing and packaging sectors.

- Q: This question asks about the various types of aluminum profiles that are utilized for the purpose of exterior wall cladding.

- <p>Aluminum profiles for exterior wall cladding come in various types, each serving specific design and structural needs. Common types include: 1. Flat Profiles, which are simple and versatile for basic cladding. 2. Box Profiles, offering a sleek, modern look and are often used for commercial buildings. 3. L-Profiles, used for corner sections and providing structural support. 4. U-Channels, which are used for concealing fasteners and creating a clean appearance. 5. Angle Profiles, used for creating corners and edges. 6. Special Profiles, designed for specific architectural features. Each type is chosen based on the aesthetic, structural integrity, and weather resistance required for the project.</p>

- Q: This question asks for a comparison between aluminum profiles and other building materials regarding their cost and performance.

- <p>Aluminum profiles are often more cost-effective than materials like steel or wood in the long run due to their durability and low maintenance requirements. They offer high strength-to-weight ratios, making them ideal for structures where weight is a concern. Additionally, aluminum profiles have excellent resistance to corrosion and weathering, which reduces the need for repainting or replacement over time. They are also energy-efficient, as they can help in reducing heat transfer, thus lowering energy costs for heating and cooling. However, the initial cost of aluminum profiles can be higher than some alternatives, but their long-term performance and low maintenance can offset this initial expense.</p>

- Q: What are the benefits of using aluminum profiles in interior design?

- Aluminum profiles offer numerous advantages when incorporated into interior design. To begin, their versatility allows for a wide range of applications. They can be easily customized and fabricated to meet various design requirements, whether it be for a modern or traditional interior. This flexibility makes aluminum profiles an ideal solution. Furthermore, despite their lightweight nature, aluminum profiles are remarkably durable. They resist corrosion, moisture, and temperature changes, ensuring a long lifespan. This durability also translates into minimal maintenance, saving time and money in the long term. Another benefit lies in the aesthetic appeal of aluminum profiles. With various finishes, colors, and textures available, designers can achieve their desired look and feel. Aluminum profiles can be anodized, powder-coated, or polished, resulting in a sleek and contemporary appearance. Additionally, they can mimic other materials like wood or stainless steel while retaining the advantages aluminum offers. Moreover, aluminum profiles possess excellent thermal and acoustic insulation properties. They regulate temperature and reduce noise levels, creating a more comfortable and serene environment. This proves especially advantageous in spaces where soundproofing or energy efficiency is essential, such as offices, hotels, or residential areas. Lastly, aluminum profiles contribute to eco-friendliness and sustainability. Aluminum is highly recyclable, and incorporating it into interior design helps reduce waste and minimize environmental impact. Furthermore, these profiles enhance energy efficiency by allowing natural light to enter a space, minimizing the need for artificial lighting during daylight hours. In conclusion, the advantages of aluminum profiles in interior design encompass versatility, durability, aesthetic appeal, thermal and acoustic insulation, and sustainability. These qualities make aluminum profiles a favored choice for designers and architects seeking to create functional and visually captivating spaces.

- Q: Can aluminum profiles be used in sports equipment manufacturing?

- Yes, aluminum profiles can be used in sports equipment manufacturing. Aluminum is a popular choice in the manufacturing of sports equipment due to its lightweight yet durable properties. It allows for the creation of strong and sturdy equipment that is also easy to handle and maneuver. Aluminum profiles can be used in various sports equipment such as bicycles, tennis rackets, golf clubs, ski poles, and even lightweight frames for sports wheelchairs. The versatility and strength of aluminum make it an ideal material for sports equipment manufacturing, providing athletes with reliable and high-performance gear.

- Q: How do you ensure proper electrical grounding with aluminum profiles?

- To ensure proper electrical grounding with aluminum profiles, it is important to follow a few steps. Firstly, it is crucial to clean the surface of the aluminum profiles thoroughly to remove any dirt, oil, or oxidation. This can be done using a suitable cleaning agent or abrasive pad. Next, make sure that the electrical connections are securely fastened to the aluminum profiles using appropriate connectors. Additionally, using conductive paste or gel can help improve the conductivity between the electrical connections and the aluminum profiles. Finally, regularly inspect the grounding system to check for any signs of damage or deterioration, and promptly address any issues that may arise.

Send your message to us

Aluminum Construction Profiles - AA1050 Mill-Finished Aluminum Coils C.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords