Aluminum Siding Profiles - AA3XXX Mill-Finished Aluminum Coils D.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

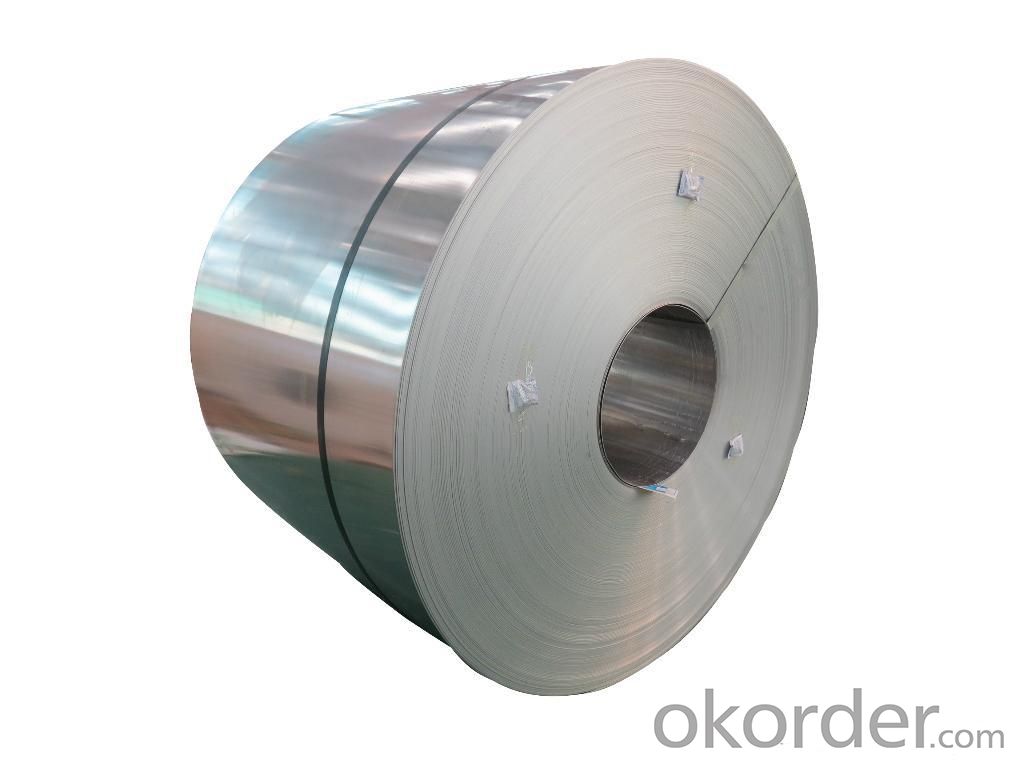

1.Structure of AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction Description

AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

3.AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction Images

4.AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction Specification

Alloy | AA3xxx (AA3003, AA3105 etc.) |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction.

B.When will you deliver the products?

AA3xxx Mill-Finished Aluminum Coils D.C Quality Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: Can aluminum profiles be used in window and door manufacturing?

- Window and door manufacturing can utilize aluminum profiles. Aluminum is a favored material for window and door frames because of its numerous advantages. It is light in weight, long-lasting, resistant to corrosion, and offers a superb strength-to-weight ratio. Aluminum profiles can be easily molded and tailored to fit various window and door designs, enabling flexibility in the manufacturing process. Moreover, aluminum frames require minimal maintenance throughout their lifespan. They also possess exceptional thermal and sound insulation properties, making them energy-efficient and capable of reducing noise transmission. In conclusion, the versatility, durability, and performance benefits of aluminum profiles make them extensively employed in window and door manufacturing.

- Q: Can aluminum profiles be used for greenhouse construction?

- Indeed, greenhouse construction can make use of aluminum profiles. The durability, lightweight characteristics, and corrosion resistance of aluminum make it a favored selection for greenhouse frames. Moreover, aluminum proves to be easily manageable, enabling flexibility in design and construction. The utilization of aluminum profiles yields a robust and steady structure capable of enduring severe weather conditions and providing enduring support for greenhouse coverings. Furthermore, aluminum frames necessitate minimal upkeep and possess a lengthier lifespan in comparison to alternative materials, rendering them a cost-efficient choice for greenhouse construction.

- Q: Are aluminum profiles suitable for use in automotive body structures?

- Yes, aluminum profiles are suitable for use in automotive body structures. Aluminum is a lightweight and durable material that offers several advantages in the automotive industry. Its high strength-to-weight ratio makes it an ideal choice for constructing body frames, panels, and other structural components. Using aluminum profiles in automotive body structures offers benefits such as improved fuel efficiency, as the lighter weight of the material reduces the overall weight of the vehicle. This, in turn, allows for better acceleration and handling. Additionally, aluminum possesses excellent corrosion resistance, which is crucial for withstanding harsh environmental conditions and extending the lifespan of the vehicle. Furthermore, aluminum profiles can be easily shaped and formed into complex designs, allowing for greater design flexibility in automotive body structures. This versatility enables manufacturers to create more aerodynamic and visually appealing vehicles. While aluminum profiles offer numerous advantages, there are also some considerations to be aware of. Aluminum can be more expensive than traditional steel, which may impact the overall cost of the vehicle. Additionally, the repair and maintenance of aluminum structures may require specialized equipment and expertise. However, these factors are outweighed by the benefits aluminum profiles bring to the automotive industry. In conclusion, aluminum profiles are indeed suitable for use in automotive body structures. Their lightweight, durable, and corrosion-resistant properties, along with their design flexibility, make them an excellent choice for constructing modern vehicles.

- Q: Can aluminum profiles be used in outdoor applications?

- Indeed, outdoor applications can make use of aluminum profiles. Aluminum proves to be a versatile and sturdy substance, exhibiting resistance against corrosion and weathering, thus rendering it apt for outdoor purposes. In the realm of construction, aluminum is frequently employed in the creation of outdoor structures such as fences, railings, pergolas, and outdoor furniture. Furthermore, aluminum profiles can undergo treatments involving diverse coatings or finishes to augment their endurance against UV rays, moisture, and other elements of the environment. In conclusion, aluminum profiles provide a dependable and enduring resolution for outdoor applications.

- Q: Can aluminum profiles be customized?

- Yes, aluminum profiles can be customized. Aluminum is a versatile material that can be easily shaped and modified to meet specific requirements. Customization of aluminum profiles can include various processes such as cutting, drilling, bending, welding, and surface treatments like anodizing or powder coating. These customization options allow for the creation of unique shapes, sizes, and finishes to suit specific applications and design needs. Whether it is for architectural, industrial, or decorative purposes, aluminum profiles can be tailored to meet individual specifications, making them a popular choice in various industries.

- Q: Can aluminum profiles be used for exhibition stands or booths?

- Yes, aluminum profiles can be used for exhibition stands or booths. Aluminum is a popular choice for building exhibition stands and booths due to its lightweight yet durable nature. It provides structural stability while being easy to transport and assemble. Aluminum profiles can be easily customized and incorporated into various designs and configurations, making them versatile for different exhibition requirements. Additionally, aluminum is a highly recyclable material, aligning with sustainable practices often sought after in exhibition and event industries. Overall, aluminum profiles offer a cost-effective and practical solution for creating exhibition stands or booths.

- Q: What are the differences between the 6005 and 6003 aluminum profiles?Yangmingxg3

- 6003 of the magnesium content is higher than 6005, and the strengthening of magnesium to aluminum is remarkable. With the addition of 1% mg, the tensile strength increases by about 34MPa.

- Q: This question asks for guidance on ensuring a safe and efficient installation process for aluminum profiles.

- <p>To ensure a safe and efficient installation process for aluminum profiles, follow these steps: Use appropriate safety gear such as gloves and goggles. Ensure the profiles are of high quality and fit for purpose. Plan the installation carefully, marking out the positions accurately. Use the correct tools for cutting and drilling, and ensure they are sharp and well-maintained. Install the profiles in a clean, dry environment to prevent damage. Follow the manufacturer's guidelines for assembly and use the correct fasteners. Regularly inspect the installation for any signs of wear or damage. By adhering to these practices, you can ensure a safe and efficient installation process.</p>

- Q: Can aluminum profiles be used for signage?

- Signage can indeed utilize aluminum profiles. Aluminum, a material known for its versatility and durability, is commonly utilized in various signage applications. It boasts numerous advantages, including its lightweight nature, resistance to corrosion, and ease of manipulation. Aluminum profiles can be effortlessly shaped into diverse forms and sizes, rendering them suitable for a vast array of signage needs. Furthermore, these profiles can be powder coated or painted to attain the desired color and finish, thereby enhancing the signage's overall appearance. Notably, aluminum is an environmentally friendly option for signage projects as it is highly recyclable, contributing to its sustainability. All in all, due to their durability, versatility, and aesthetic appeal, aluminum profiles remain a favored choice for signage projects.

- Q: What are the different surface embossing options for aluminum profiles?

- There are several surface embossing options available for aluminum profiles, each offering unique textures and patterns. Some of the most commonly used options include: 1. Diamond pattern: This embossing option creates a diamond-shaped pattern on the surface of the aluminum profile. It provides a visually appealing texture and enhances the grip of the profile, making it suitable for applications that require slip resistance. 2. Stucco pattern: Stucco embossing creates a textured surface with small, raised bumps. This pattern is commonly used in applications where aesthetics are important, such as architectural facades or interior design elements. 3. Hammer tone pattern: This embossing option creates a hammered texture on the surface of the aluminum profile. It gives a unique and rustic appearance, making it popular for decorative applications like furniture or light fixtures. 4. Wood grain pattern: Wood grain embossing mimics the texture and appearance of natural wood. This option is often chosen to achieve a more traditional or natural look in applications like window frames or doors. 5. Linen pattern: Linen embossing creates a subtle, fabric-like texture on the surface of the aluminum profile. This pattern is commonly used in applications that require a sophisticated and elegant finish, such as interior decorative panels or cabinet doors. It's important to note that these embossing options can be combined or customized to suit specific design requirements. Manufacturers may offer additional embossing options, allowing customers to choose from a wide range of patterns and textures to achieve their desired aesthetic and functional goals.

Send your message to us

Aluminum Siding Profiles - AA3XXX Mill-Finished Aluminum Coils D.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords