All Aluminum Coil - AA1XXX Mill-Finished Aluminum Coils C.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

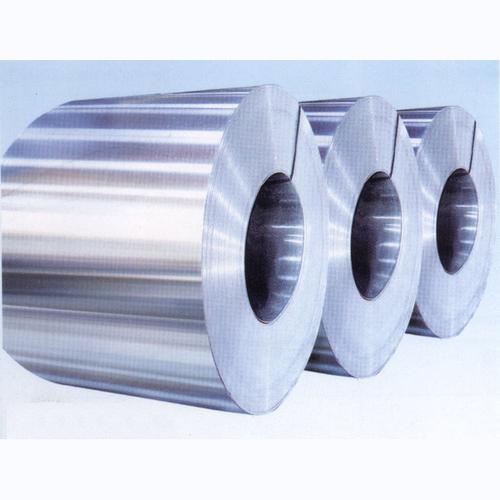

1.Structure of AA1xxx Mill-Finished Aluminum Coils C.C Quality Used for Construction Description

AA1xxx Mill-Finished Aluminum Coils C.C Quality Used for Construction is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

2.Main Features of AA1xxx Mill-Finished Aluminum Coils C.C Quality Used for Construction

1)excellent quality,good credit

2)competitive price,comfortable service

3)Samples for free

4)fast delivery,small order accepted

5)Good rust resistance

6)clean, flat, no wrinkle, no scratch, oil free.

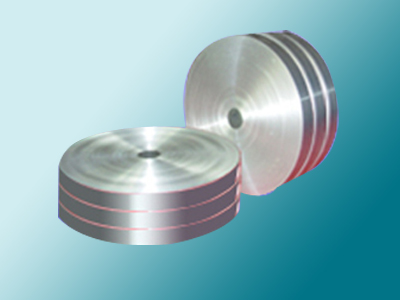

3.AA1xxx Mill-Finished Aluminum Coils C.C Quality Used for Construction Images

4.AA1xxx Mill-Finished Aluminum Coils C.C Quality Used for Construction Specification

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc. |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA1xxx Mill-Finished Aluminum Coils C.C Quality Used for Construction

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Are aluminum coils easy to bend and shape?

- Yes, aluminum coils are relatively easy to bend and shape. Aluminum is a malleable metal, which means it can be easily deformed under compression without breaking. This property makes it highly suitable for shaping and forming into various shapes and sizes. Additionally, aluminum coils can be manipulated using different techniques such as rolling, bending, or pressing, allowing for a wide range of applications in industries such as construction, automotive, and manufacturing. However, the ease of bending and shaping aluminum coils may also depend on the specific alloy and thickness of the coil. Thicker coils may require more force and specialized equipment for shaping, while certain alloys may have different levels of malleability. Overall, aluminum coils offer a versatile and relatively easy-to-work-with material for bending and shaping purposes.

- Q: Can aluminum coils be used in low-friction applications?

- Yes, aluminum coils can be used in low-friction applications. Aluminum's low coefficient of friction and excellent thermal conductivity make it a suitable material for various applications where low friction is desired, such as in sliding mechanisms, bearings, and electrical connectors.

- Q: Which is better - a steel roof or an aluminum roof?

- Steel! SteelMaster steel roofs are Energy Star rated with Galvalume Plus coating and a 30 year warranty. Our steel roofs are custom designed and engineered to meet the loads and codes required for permitting.

- Q: Can aluminum coils be used for marine applications?

- Yes, aluminum coils can be used for marine applications. Aluminum is a popular material choice for marine applications due to its excellent corrosion resistance in saltwater environments. It has a natural oxide layer that forms on its surface, providing protection against corrosion. Aluminum coils are commonly used for marine applications such as boat hulls, decks, and structures. Additionally, aluminum is lightweight, which contributes to fuel efficiency and improved performance in marine vessels. Its high strength-to-weight ratio makes it an ideal choice for constructing boats and other marine equipment. However, it is important to select the appropriate grade of aluminum alloy that is specifically designed for marine applications to ensure optimal performance and longevity.

- Q: Who knows Xingtai aluminum shutter door how much is one square meter?

- East of the ox horn, that is, the South and the junction, then ask yourself, will not be a big difference

- Q: What is the common color of aluminum coil membrane?

- The blue transparent membrane is the most common.

- Q: What industries commonly use aluminum coils?

- Several industries commonly use aluminum coils due to the many beneficial properties of aluminum. One of the largest consumers of aluminum coils is the automotive industry, where they are used in the manufacturing of various components such as radiators, condensers, and heat exchangers. The construction industry also extensively utilizes aluminum coils for applications like roofing, gutters, and siding due to their lightweight, corrosion-resistant, and durable nature. Aluminum coils are also widely used in the HVAC (heating, ventilation, and air conditioning) industry for the production of air handling units, heat pumps, and ductwork. The electrical industry utilizes aluminum coils in the production of transformers, as aluminum's high electrical conductivity makes it an excellent choice for these applications. Additionally, the packaging industry often employs aluminum coils for the production of cans, containers, and foils. Aluminum's ability to form a protective oxide layer and its excellent heat conductivity are particularly advantageous in packaging applications. Other industries that commonly use aluminum coils include aerospace, marine, and transportation, where their lightweight nature helps improve fuel efficiency and enhance performance. Overall, the versatility, durability, and excellent physical properties of aluminum make it a preferred choice of material for numerous industries that rely on aluminum coils for various applications.

- Q: How do aluminum coils contribute to the aesthetics of a building?

- The versatility, durability, and aesthetic appeal of aluminum coils significantly enhance the aesthetics of a building. Firstly, aluminum coils offer flexibility in achieving the desired aesthetic by easily shaping and forming them into various architectural designs. Whether it's a sleek modern look or a more traditional design, aluminum coils can be customized to meet specific aesthetic requirements. Additionally, architects and designers have a diverse palette of colors and finishes to choose from when using aluminum coils. This wide range of options allows for endless possibilities in creating visually appealing facades and exteriors that match the overall theme or style of the building. Moreover, aluminum's durability and resistance to corrosion make it an ideal material for architectural applications. By using aluminum coils, the exterior surfaces of a building can maintain their aesthetic appeal for an extended period with minimal maintenance required. This long-lasting beauty makes aluminum coils a cost-effective choice for maintaining the aesthetics of a building. Furthermore, aluminum coils contribute to the energy efficiency of a building. They have excellent thermal conductivity, which effectively dissipates heat and reduces energy consumption for temperature control. This energy-saving feature not only enhances the sustainability of a building but also adds to its overall aesthetic appeal by incorporating environmentally conscious design elements. In conclusion, the use of aluminum coils in a building contributes to its aesthetics through design flexibility, a wide range of color and finish options, durability, and energy efficiency. These qualities allow architects and designers to create visually appealing structures that align with the desired aesthetic vision while ensuring long-lasting beauty and sustainability.

- Q: What precautions should be taken when handling aluminum coils to ensure safety?

- <p>When using aluminum coils, safety measures include wearing appropriate personal protective equipment such as gloves and safety glasses to prevent cuts and eye injuries. Ensure the work area is well-ventilated to avoid inhaling fumes from any processes involving the coils. Keep the coils dry to prevent electrical hazards. Use proper handling equipment to avoid back injuries from heavy loads. Always follow the manufacturer's guidelines for the specific aluminum coil products being used. Regularly inspect the coils for any signs of damage or wear that could lead to accidents.</p>

- Q: Is it possible to use an electric stove with an aluminum coil heater?

- <p>Yes, you can use an electric stove with an aluminum coil heater. However, it's important to ensure that the aluminum coil heater is designed for use with an electric stove. Aluminum is a good conductor of heat and can be used in heating elements. Make sure the heater is compatible with the stove's power requirements and that it's installed correctly to avoid any safety hazards. Always follow the manufacturer's instructions for installation and use.</p>

Send your message to us

All Aluminum Coil - AA1XXX Mill-Finished Aluminum Coils C.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords