Ic Grade Solar Silicon Wafer Supplier - 6 inch 3bb Monocrystalline Best Solar Cell Price 17.6%

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: | China (Mainland) | Brand Name: | xrsolar | Model Number: | ERC-156M-3BB |

Material: | Monocrystalline Silicon | Size: | 6 inch | Number of Cells: | 1 |

Max. Power: | 4.3W | Material:: | monocrystalline Silicon | Size:: | 156mmx156mm or 6 inch |

Max. Power:: | 4.3 watts | efficiency:: | 16%-17.8% | busbar:: | 3 |

Color: | Dark Blue | Voltage:: | 0.508V-0.53V | Thickness:: | 190um±20um |

Packaging & Delivery

Packaging Details: | 100pcs in one box,1000pcs per carton, standard export carton |

Delivery Detail: | 5-7 days after received the payment |

Specifications

3BB Monocrystallin Best Solar Cell Price

1.Size: 6*6 solar cell

2. Efficiency:4.3WMonocrystallin Best Solar Cell Price

6 Inch 3BB Monocrystallin Best Solar Cell Price

Dimension: 156mm x 156mm

Diagonal: 200mm (round chamfers)

Front: Anisotropically texturized surface and dark silicon nitride

anti-reflection coating

1.9mm silver busbars

Back: Full-surface aluminum back-surface field

4.0mm (silver / aluminum) continuous soldering pads

Features

1.High conversion efficiencies resulting in superior power output performance.

2.Outstanding power output even in low light or high temperature conditions

3.Optimized design for ease of soldering and lamination

4.Long-term stability,reliability and performance

5.Low breakage rate

6.Color uniformaity

Packaging & Shipping

1. Item are only shipped after PAYMENT is received.

2.Originally our solar cells are 100 pieces per box, 10 boxes per carton.

2. Please check out your ADDRESS carefully when processing order.

3. Please CONTACT us ASAP if you haven't received the parcel.

Shipping will be made via EMS, DHL, Fedex, UPS , TNT etc

FAQ:

FAQ:

1. Q: Do you have your own factory?

A: Yes, we have. Our factory located in Jiangsu

2. Q: How can I visit your factory?

A: Before you visit,please contact us.We will show you the route or arrange a car to pick you up.

3. Q: Do you provide free sample?

A: Commenly we provide paid sample.

4. Q: Could you print our company LOGO on the nameplate and package?

A: Yes, we accept it.And need an Authorization Letter from you.

- Q: How does the efficiency of a solar silicon wafer vary with different angles of sunlight?

- The efficiency of a solar silicon wafer typically varies with different angles of sunlight. As the angle of sunlight changes, the amount of solar energy reaching the surface of the wafer also changes. Generally, the efficiency tends to decrease as the angle of sunlight deviates from perpendicular (90 degrees) to the wafer's surface. This decrease occurs because the solar energy is spread over a larger area, reducing the intensity of the light absorbed by the silicon material. Therefore, it is important to optimize the orientation and tilt of solar panels to maximize their efficiency by capturing sunlight at the most favorable angles throughout the day.

- Q: Can solar silicon wafers be used in solar-powered irrigation systems?

- Yes, solar silicon wafers can be used in solar-powered irrigation systems. These wafers are commonly used in solar panels to convert sunlight into electricity, which can then be utilized to power irrigation systems. By harnessing solar energy, these systems provide a sustainable and renewable source of power for irrigation, reducing reliance on traditional electricity sources and promoting eco-friendly farming practices.

- Q: What is a silicon wafer for unidirectional and bidirectional cutting? What is the difference between the two?

- The cutting line is cut in one direction, and the wire is cut into the waste wire wheel from the discharge wheel

- Q: How are solar silicon wafers cleaned and maintained?

- Solar silicon wafers are cleaned and maintained through a combination of mechanical and chemical processes. The cleaning process typically involves removing dust, dirt, and other contaminants that accumulate on the surface of the wafers. This is done using brushes, deionized water, and mild cleaning solutions. Additionally, regular maintenance includes monitoring the performance of the solar panels, inspecting for any damages or defects, and ensuring proper functioning of the electrical connections.

- Q: How is the silicon chip integrated circuit?

- Description: the above process is only an example. The name of the process, in the name of different manufacturers have different. But roughly so. There are some differences between the process of MOS circuit and.

- Q: Can solar silicon wafers be used in solar-powered desalination plants?

- Yes, solar silicon wafers can be used in solar-powered desalination plants. These wafers are commonly used in photovoltaic (solar) panels to convert sunlight into electricity. By integrating solar silicon wafers into the desalination process, solar energy can be harnessed to power the plant's operations, reducing reliance on traditional energy sources and making the desalination process more sustainable.

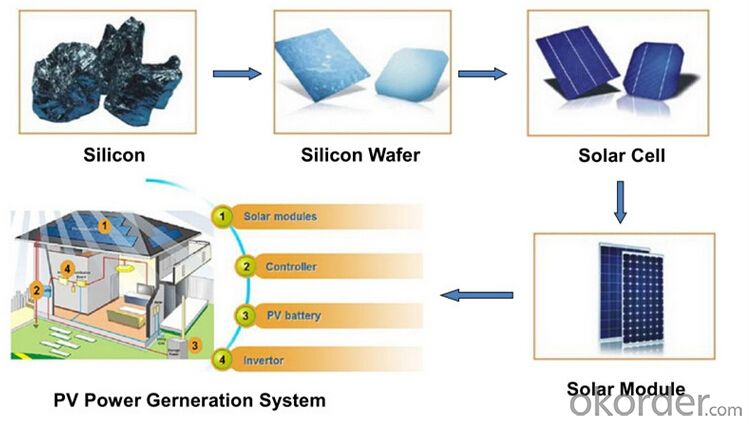

- Q: What is a silicon wafer

- Is usually used in high-end IC and special IC, such as Si on insulator (SOI) wafer. In the production process of IC, need some wafer to test the status of the production process, such as the level of particle, the etching rate, defect rate and so on, these are often called wafer control chip, the control plate is also used with normal production batch process together to test the quality condition of a process, such as the CVD film thickness. In the production equipment maintenance or repair, immediately production batch of wafer, easy to cause the scrap, and usually use some very low cost wafer to run the process to determine the quality of maintenance or repair work, which is usually called wafer dummy wafer, of course, sometimes dummy wafer also can be used in the normal production process, such as machine must wafer to process a number of problems with dummy wafer complement, and some machines must be in the process of a certain number of wafer A form of dummy run, otherwise the process can not guarantee the quality and so on many wafer and so on can be called dummy. block basically can be regarded as a kind of.Dummy wafer dummy, wafer control chip, a guard sheet usually can be recycled.

- Q: What is the purpose of an anti-reflective coating on a solar silicon wafer?

- The purpose of an anti-reflective coating on a solar silicon wafer is to minimize the amount of light that is reflected off the surface of the wafer. By reducing reflection, more light can be absorbed by the solar cells, resulting in increased efficiency and energy production.

- Q: How is the surface of a solar silicon wafer treated?

- The surface of a solar silicon wafer is treated through a combination of cleaning and texturization processes. Initially, the wafer is cleaned to remove any impurities or contaminants. This is typically done using a combination of chemical and mechanical cleaning methods. After cleaning, the surface is texturized to increase its light absorption capability. One common method is to etch the surface using a mixture of chemicals, creating a rough texture. This textured surface helps to trap and scatter light, enhancing the efficiency of the solar cell. Once treated, the surface is typically coated with a thin layer of anti-reflective material to further improve light absorption. The treated wafer is then ready to be used in the fabrication of solar cells.

- Q: How are solar silicon wafers handled during installation?

- During installation, solar silicon wafers are carefully handled to ensure their safety and efficiency. They are typically packaged and transported in protective trays or boxes to prevent any damage or contamination. During the installation process, technicians use specialized tools and equipment to handle the wafers with care, minimizing any physical contact that could potentially harm or scratch their delicate surfaces. Additionally, safety protocols are followed to avoid exposure to dust, moisture, or other harmful elements that could negatively impact the wafers' performance.

Send your message to us

Ic Grade Solar Silicon Wafer Supplier - 6 inch 3bb Monocrystalline Best Solar Cell Price 17.6%

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords