1100-H124 aluminium sheet and aluminium slab in warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series, etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

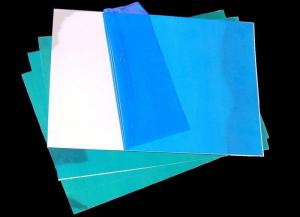

3. Image

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

- Q:Can aluminum sheets be used for roof flashing?

- Yes, aluminum sheets can be used for roof flashing. Aluminum is a popular choice for roof flashing due to its durability, corrosion resistance, and lightweight properties. It provides a reliable barrier against water penetration and helps to redirect water away from vulnerable areas on the roof, such as valleys and chimneys. Additionally, aluminum flashing is relatively easy to install and maintain, making it a practical choice for roof flashing purposes.

- Q:Are 101 aluminum sheets suitable for food-grade applications?

- No, 101 aluminum sheets are not suitable for food-grade applications.

- Q:What are the applications of aluminum sheet?

- Aluminum sheets have a wide range of applications due to their unique properties and versatility. Some of the common applications of aluminum sheets include: 1. Construction: Aluminum sheets are widely used in the construction industry for roofing, siding, and cladding purposes. Their lightweight nature makes them easy to handle and install, while their corrosion resistance ensures long-lasting durability. 2. Transportation: Aluminum sheets are extensively used in the automotive industry for manufacturing vehicle bodies, panels, and structural components. Their high strength-to-weight ratio helps reduce the overall weight of vehicles, increasing fuel efficiency and improving performance. 3. Packaging: Aluminum sheets are commonly used in the packaging industry for manufacturing cans, foils, and containers. Aluminum foils are used for food packaging, as they provide a barrier against moisture, light, and oxygen, ensuring the freshness and safety of the packaged products. 4. Electrical: Aluminum sheets are used in the electrical industry for manufacturing power transmission lines, busbars, and electrical enclosures. Their excellent electrical conductivity helps in the efficient transmission of electricity, while their corrosion resistance ensures longevity in outdoor applications. 5. Marine: Aluminum sheets are widely used in the marine industry for manufacturing boat hulls, decks, and superstructures. Their resistance to corrosion from saltwater makes them ideal for marine applications, while their lightweight nature helps reduce the overall weight of the vessel. 6. Aerospace: Aluminum sheets are extensively used in the aerospace industry for manufacturing aircraft and spacecraft components. Their high strength-to-weight ratio and excellent thermal conductivity make them suitable for applications where weight reduction and heat dissipation are critical. 7. Heat exchangers: Aluminum sheets are used in the manufacturing of heat exchangers, such as radiators and condensers. Their high thermal conductivity allows for efficient heat transfer, making them ideal for applications where heat exchange is required. 8. Decorative: Aluminum sheets are commonly used in interior design and architectural applications for decorative purposes. They can be easily shaped, bent, and formed into various designs, adding a modern and aesthetic appeal to buildings and interiors. Overall, aluminum sheets find applications in various industries due to their lightweight nature, corrosion resistance, high strength-to-weight ratio, and excellent thermal conductivity.

- Q:How does the thermal conductivity of aluminum compare to other metals?

- Compared to many other metals, aluminum boasts a relatively high thermal conductivity. It is often hailed as one of the foremost heat conductors among common metals. With a thermal conductivity of approximately 205 watts per meter kelvin (W/m·K), aluminum surpasses copper (about 401 W/m·K) and even silver (about 429 W/m·K). As a result, aluminum excels at efficiently transferring heat, making it a widely favored option for heat sinks, radiators, and various applications necessitating effective heat dissipation. Nonetheless, it is worth mentioning that certain metals, such as diamond and graphene, surpass aluminum in terms of thermal conductivity.

- Q:I have some carbon arrows for my bow but I was wondering if aluminum arrows penetrate farther into a deer because they weigh more. I read somewhere that they do but I just wanted to confirm that.

- With the speed you pick up with some light carbons, the extra mass of an aluminum is irrelevant. Carbons are also much more durable. They don't bend, but only break, where as aluminum's bend quite easily. Besides, you can get complete pass through with carbons, so you don't really need more penetration.

- Q:What is the electrical resistivity of 101 aluminum sheets?

- The electrical resistivity of 101 aluminum sheets can vary depending on the specific grade and condition of the aluminum. However, on average, aluminum has an electrical resistivity of about 2.65 x 10^-8 ohm-meters. It is important to note that this value may slightly vary due to impurities or other factors.

- Q:What are the different types of alloys used for painted aluminum sheets?

- Painted aluminum sheets commonly utilize various types of alloys. Among them, 3003 stands out as a favored option due to its exceptional corrosion resistance and high formability. This alloy finds extensive use in industries like automotive, where a smooth surface finish is preferred. Another frequently employed alloy is 5052, which provides superior strength compared to 3003. Its remarkable resistance to corrosion and ability to endure harsh environments make it suitable for marine and architectural applications. Moreover, it is renowned for its weldability and formability. 6061 is also a well-liked choice for painted aluminum sheets. Its notable attributes include high strength and excellent machinability. This alloy is often employed in structural applications, such as the production of aircraft parts and automotive components. Furthermore, painted aluminum sheets may incorporate other alloys like 2024, 5754, and 7075. These alloys possess specific properties that render them suitable for particular applications, such as elevated strength or improved corrosion resistance. In essence, the selection of the alloy for painted aluminum sheets hinges upon the specific requirements of the application, such as desired strength, corrosion resistance, and formability.

- Q:I have a specific design I'd like to cut out of thin sheet metal (aluminum or tin) and I'm wondering how to make it more sturdy. The sheet metal is a bit flimsy. Can I strengthen it by heating it up (butane torch) and cooling it quickly?

- This Site Might Help You. RE: Can you temper aluminum or tin? I have a specific design I'd like to cut out of thin sheet metal (aluminum or tin) and I'm wondering how to make it more sturdy. The sheet metal is a bit flimsy. Can I strengthen it by heating it up (butane torch) and cooling it quickly?

- Q:Can aluminum sheets be used for heat sinks in LED lighting?

- Yes, aluminum sheets can be used for heat sinks in LED lighting. Aluminum is an excellent conductor of heat, and its high thermal conductivity makes it an ideal material for dissipating heat generated by LED lights. The use of aluminum sheets as heat sinks helps to transfer the heat away from the LED chips, preventing overheating and prolonging the lifespan of the LED lighting system. Additionally, aluminum is lightweight, corrosion-resistant, and cost-effective, making it a popular choice for heat sink applications in LED lighting.

- Q:I'm about to fix the aluminum wiring in my house using Alumiconn connection, so I know that every outlet and switch plate need to be done, do the light fixtures need to be done as well? And also does anything need to be done with the main circuit breaker?

- Normally, the houses are ceiling with copper wires on the walls instead of aluminum. Because of safe secure and also cost effective. Better to replace all the things.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1100-H124 aluminium sheet and aluminium slab in warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords