Pigment Powder TiO2 Price for Raw Material of Paint

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

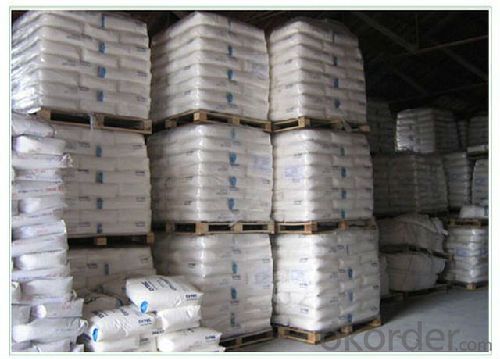

- Supply Capability:

- 140000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Titanium dioxide pigment (TiO2) is a white powder with high opacity, brilliant whiteness, excellent covering power and resistanc .

1, White powder

2, Molecular Formula: TiO2

3, CAS NO.: 13463-67-7

4, Type: Titanium Dioxide Anatase 98.5%, Rutile 93%

5. Color: Super white

Properties of Pigment Powder TiO2 Price for Raw Material of Paint

White powder, insoluble in water, soluble in hot and concentrated strong acid and alkali, having the good chemical stability; It has strong achromatic power, covering power, with excellent properties of pigment.

Application of Pigment Powder TiO2 Price for Raw Material of Paint

1) In paint industry, It is used as white pigment and glaze of porcelain.

2) It can also be used as coating and filling in paper-making industry to help paper to be printable and opaque.

3) In metallurgical industry, it can be used to make spongy titanium, alloy of titanium and iron and hard alloy.

4) It can also be used to make nonconductor, electric welding rod and porcelain enamel.

5) It can also be used in synthetic fibre, plastic, rubber, printing, dying, cosmetics, medicine fillings and food additives.

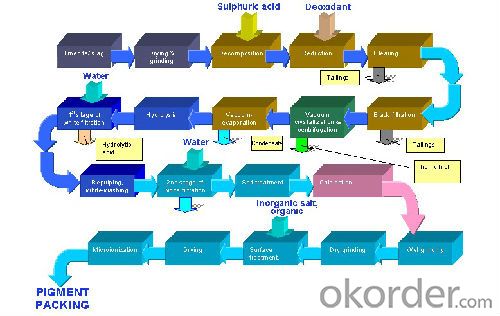

Analysis of Pigment Powder TiO2 Price for Raw Material of Paint

item | titanium dioxide rutile | titanium dioxide anatase |

TiO2 | 93.0min | 98.0min |

Whiteness, | 98.0 min | 98.0min |

Tint strength, | 180min | 100 min. |

L. O. I, | 0.1max | 0.2 max |

PH | 6.5-8.0 | 6.5-8.0 |

Residue on Sieve 45μ m, | 0.05max | 0.05 max |

Oil absorption (g/100g) | 26max | 22 max |

Water Soluble Matter, | 0.5max | 0.2 max |

Solution of acid, | 0.5max | 0.5 max |

- Q:Plastic paint and metal paint the difference? I use metal paint spray plastic will play from the skin Will you master how is it? Thank you!

- Big job for example: just as sick to see a doctor, the doctor open the wrong medicine, and the patient has a side effect after taking medicine.

- Q:Does the company lay off the painter?

- Need to carry out occupational examination, because the painters are special types of work, need to do pre-job examination, post in the physical examination and physical examination.

- Q:Bought a cell phone, but also want to buy a mobile power. Looked at the Internet, mobile power in the battery there are three, but also check the investigation do not know which battery is better. The recent explosion of mobile power has occurred, so it is also more worried about this. If there is a good mobile power recommended. Thank you first.

- Soft lithium-ion battery (polymer battery) has a higher energy density, better performance and performance of any shape and other characteristics, as the majority of mainstream digital products, the preferred cell, but compared to steel lithium-ion battery , The price is still high.

- Q:Is there a website for reference? Thank you

- Not the same, each have their own role.

- Q:What is the difference between latex paint and whitening? What is the difference between the surface and the surface?

- Scraping is actually in the roller brush wall paint before the wall on the grass-roots treatment behavior, is matched with the brush latex paint. Scraping white is used as a putty to the wall leveling, until the dry after the sanding with a smooth, and then you can brush the latex paint - latex paint is the whole process of finishing the wall of a final process.

- Q:I have a question about paint!?So whats the deal with magnetic paint and dry eraser paint. Like, what is it? So its like paint and you paint it on like ordinary paint let it dry and it is magnetic or dry eraser?

- I think it's like blackboard paint. Once it dries, you can write on/ stick metal to it. That, or it's a fake and probably some super-expensive, super-ugly paint.

- Q:Kansai Paint of West Coatings

- Kansai Coatings owns the Asian markets (China, Thailand, Singapore, Malaysia, Taiwan, Hong Kong, Philippines and India), as well as the US and Mexican markets. In 2005, the company established a PPG joint venture for automotive coatings to serve the North American and European markets. In Osaka and the Tokyo Stock Exchange, listed companies announced sales of Kansai Y19.6 billion ($ 1,840,000 in 2005). 1918 years: wins yang rock well founds in the city of Nisaki, Japan Kansai paint.

- Q:Is it harmful to the body at the paint factory?

- Second, the workers should wear a mask and gloves during construction, to avoid direct contact with the skin paint; in the construction of all the windows open ventilation. In addition, usually eat more high vitamin content of food, drink plenty of water.

- Q:Want to know if the ink of L351 and L353 is pigment ink or dye ink

- Hello, L351 and L353 ink is dye ink.

- Q:How is paint made today without lead?

- Artists paints are made in much the same way they always have been: by grinding coloured powders (pigments) very finely, and mixing them with a liquid (a medium) that sets, so as to glue the colour to a surface. That's what a paint is. In the past it was done by hand (it was the one of the first jobs an artist's studio assistant would be set to work doing), now it's done by machine. Lead oxides are still used as pigments, mainly in Flake White. Safety regulations banning lead paints only apply to house paints, not artists' paints (at least in the UK), though they may have to be sold in childproof tins. Alternatives to lead include zinc and titanium, which may be mixed to give a white paint that looks similar to Flake White.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 100 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% North America 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao PORT |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 700,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Pigment Powder TiO2 Price for Raw Material of Paint

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 140000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords