The Wear-Resistant Pressure Epoxy Floor Coating

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Description:

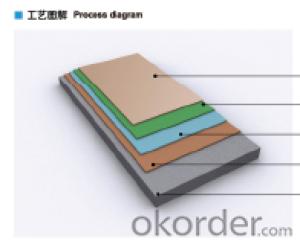

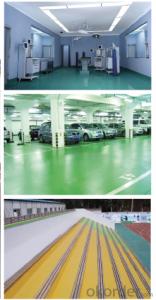

The wear-resistant weight epoxy floor coating developed adopting international advanced materials and technologies is suitable for the grounds, with high mechanical performance, and a certain impact, such as: underground garages, heavy trucks, forklifts, frequent moving rolling wheels of forklifts, accumulation of heavy cargo and large machine workshops with dustproof requirement for sophisticated technology processing and production, weight workshops of machinery and equipment, auto repair shops, electronics industry, storerooms and other places with heavy loads.

2.Main Features

* The overall ground is seamless, and is easily cleaned and will not keep hidden dust and bacteria;

* Surface wear-resistance, durable;

* Acid, alkali, salt and other corrosive chemicals resistance;

* Resistance to gasoline, oil and diesel oil erosion, not leak, easy to clean;

* The ground coating is non-toxic, and meets the health requirements;

* Rich surface colors can beautify the working environment.

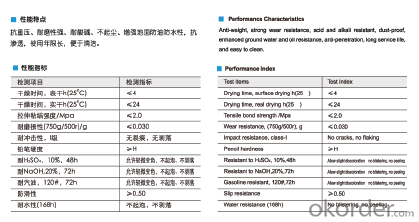

3.Technical Parameters

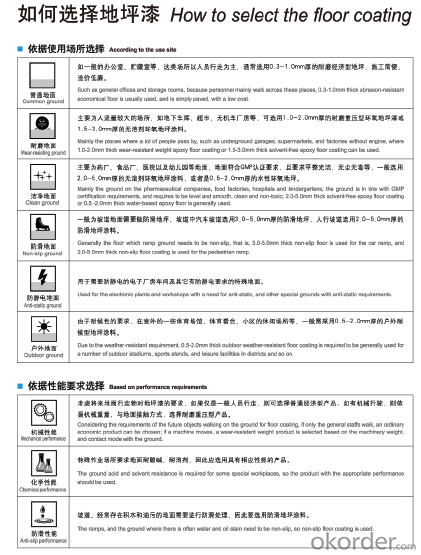

4.How to selected the floor Coating

5.Applications

What base materials is the epoxy floor coating suitable for?

Decoration of new concrete ground, and renovation of old concrete, ceramic tile, marble, terrazzo and other ground surfaces

- Q:I painted on my backpack with tempera paint, and its already started to start chipping off. Is there any way to keep the paint on more permanently?

- tempera paint with NEVER stop chipping. All paints has something called a binder, which is it's main ingredient from which it was made. Tempera is a poor quality paint whose binder is egg yolk. This is why it chips when dried. Tempera paint is common among children since they have no real talent for painting and tempera is a lot cheaper (due to chipping) so its perfect for them. No sense in wasting expensive quality paint on them unless its highschool possibly 8th grade and up. If your making quality art work try acrylic, it's more expensive but worth it

- Q:Buy paint how to buy

- look at the weight, do not sloppy, the market's packaging specifications are varied, in our, the lightest is 3 kg, the most important is 9.5 kg. You have to pay attention to the time of purchase, marked 5 kg there are two, gross weight 5 kg and net weight of 5 kg, I think the choice of which you should be very clear! 5, understand

- Q:Brush latex paint or stickers good wallpaper?

- . From the decorative effect, the wallpaper is certainly better, more rich patterns, and the film is good can be repeatedly rubbed, resistant to stains than latex paint strong!

- Q:What is the difference between ink and paint?

- Ink is an important material for printing, it is printed by the pattern, the text on the substrate. The ink contains the main ingredients and auxiliary ingredients, they are evenly mixed and repeatedly rolled into a viscous colloidal fluid. By the pigment, binder and additives and solvents and other components. For books, packaging and decoration, architectural decoration, and other printing.

- Q:Hello everyone, my home is being renovated recently, but do not know what brand of interior wall paint is better. Or how about using paint? Synthetic resin emulsion as the base material by adding pigments, fillers and various additives made of a class of water-based paint. According to the different production materials, latex paint mainly polyvinyl acetate latex paint, acrylic emulsion latex paint, pure acrylic latex paint, styrene-acrylic latex paint and other varieties; according to the product for different environments, divided into interior latex paint and exterior latex Paint two kinds; according to the decorative effect of gloss can be divided into matte, matte, semi-light, mercerizing and light and other types,

- Gas is played by advertising, in the end more environmentally friendly? We can not directly say that parameters, but you can give a conclusion, unless you buy the state of high-end products, 200, about what the fact that the domestic and 100 of the almost, paint, then we do not recommend you buy state , Nippon's paint that really is not really good, but they give the dealer's profit is high, to the painter's many rebates, so are it good! But really good or bad, only the state of its own know! I am now no longer engaged in this industry, but still hope that you can support a lot of domestic brands, such as China Resources, Bauhinia, the United States Tu disabilities, etc., is not only those famous brands can be used, There are many local brands of good quality! Hope dealers do not just see immediate benefits, you know to sell those so-called big, and denied the domestic brand! The

- Q:Chemical fiber dyes toxic

- Responsible to say, Zhejiang Longsheng, Zhejiang Runtu production of dyes are non-toxic, and passed the ISO9001 international quality management system certification and ISO14001 environment system certification.

- Q:I have seen on the introduction of the brand, the actual use of some of the situation is not very clear, said used, please talk about views, views. thank you very much!

- Hello, to paint when the best not to choose those unknown, cheap low-quality paint, choose some big brands, safety and environmental protection are more secure, the domestic paint brand is now more than the stars, substantial good paint brand But very few, but the market is more extensive, to pay attention to identify the authenticity, to find a formal channel to buy, the current domestic more environmentally friendly paint brand on the United States Tu Shi do relatively good, paint the top ten brands, but the advertising investment is not abroad Brand so much, the price will be relatively high.

- Q:1, if the use of pigment ink, will not often plug the plug after a good deal, will not lead to the printer scrapped 2, with dye ink, cold laminating film, indoor can keep how long does not fade? 2, generally sold outside the star posters and photo studio print photos are used in what kind of ink? Thank you!

- After the dye ink is printed, it is best to store it thermally. Preservation time, mainly determined by the intensity of indoor light.

- Q:When the oil paint is not enough when you can mix some gouache paint use?

- Oil paints are made from pigment powder and oil. The market for the sale of mostly tube, can also be made. The basic ingredients of oil paints and other paint pigments, such as colorants, physical pigments, vehicle and some accessories such as plastic agents, stabilizers, slow dryers or driers and other components. Ancient master paint powder used mostly from the soil and minerals. The other part comes from plants or animals.

- Q:Everyone's paint and paint are where to buy it

- Most of the people are building materials market, and some are directly recommended by the decoration company, regardless of now can also order online, choose a safe, cost-effective decoration coating is very important, Rui Peimu smart paint wish you a happy family, chicken years Big!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

The Wear-Resistant Pressure Epoxy Floor Coating

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords