Hot Rolled Steel Rail

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 10000MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Hot Rolled Steel Rail

Production Standard: GB Standard, AREMA, BS, UIC860, JIS, DIN, etc

Grade: Q235B, 55Q, 900A, 50Mn, U71Mn

| Alloy No. | Grade | C | Mn | S | P | Si |

| Q235 | B | 0.12%-0.20 | 0.3%-0.7% | <=0.045% | <=0.045% | <=0.3% |

Length: 6M, 8M, 9M, 10M, 12M, 12.5M, 24M or as the requriements of the client

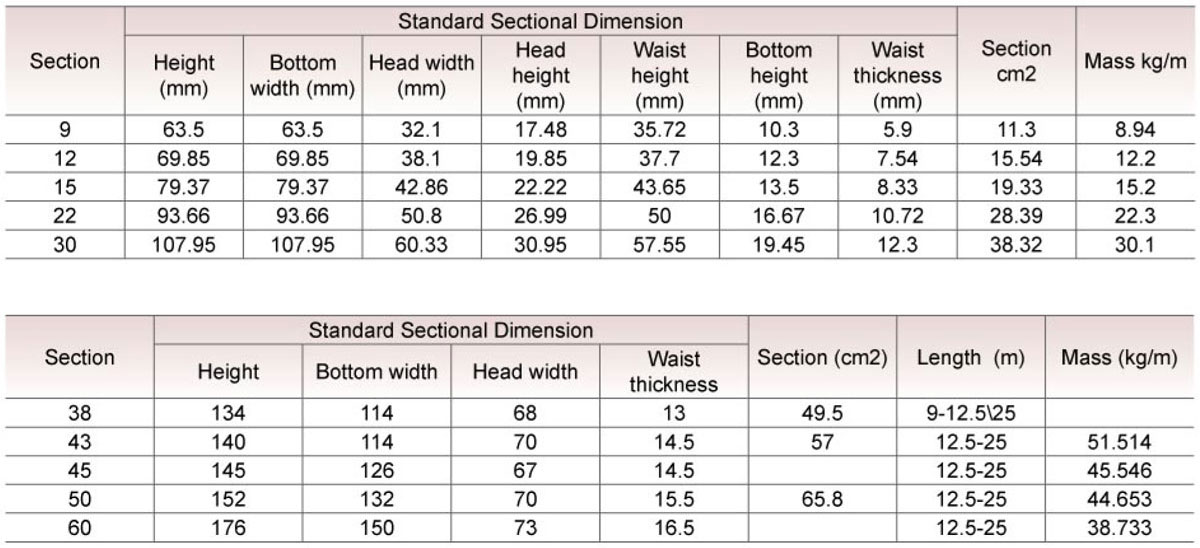

Sizes: 9kg-60kg

Usages of Hot Rolled Steel Rail

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Packaging & Delivery of Hot Rolled Steel Rail

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

7. Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Inspection of Hot Rolled Steel Rail

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q:How do steel rails contribute to the overall capacity of railway tracks?

- Steel rails contribute to the overall capacity of railway tracks in several ways. Firstly, steel rails provide a smooth and durable surface for trains to travel on, minimizing friction and allowing for efficient movement of trains. This enables trains to maintain higher speeds and reduce travel time, thus increasing the overall capacity of the railway track. Moreover, steel rails have high strength and can withstand heavy loads, allowing trains to carry more passengers or freight. This increases the capacity of the railway track by enabling trains to carry larger volumes of goods or accommodate a greater number of passengers. Additionally, steel rails are resistant to wear and tear, ensuring their longevity and reducing the need for frequent maintenance and repairs. This enhances the reliability of the railway track, minimizing downtime and maximizing the capacity of the track by allowing for uninterrupted train operations. Furthermore, steel rails provide stability and support to the train, preventing derailments and ensuring safe and secure transportation. By reducing the risk of accidents, steel rails contribute to the overall capacity of railway tracks by maintaining a continuous flow of trains without interruptions caused by accidents or derailments. Overall, the use of steel rails in railway tracks significantly enhances their capacity by facilitating efficient train movement, enabling the transportation of heavy loads, ensuring durability and reliability, and promoting safe operations.

- Q:Can steel rails be used in extreme cold temperatures?

- Yes, steel rails can be used in extreme cold temperatures. Steel is known for its durability and strength, making it suitable for various environments, including extreme cold temperatures. Steel rails are commonly used in railways all over the world, even in regions with freezing temperatures. However, it is important to note that appropriate maintenance practices should be implemented to ensure the rails' longevity and performance in extreme cold conditions. This may include regular inspections, lubrication of the rails, and prompt removal of ice or snow build-up. Additionally, steel rails are often made with specific alloys that enhance their resistance to cold temperatures, preventing cracking or brittleness. Overall, steel rails are designed to withstand extreme weather conditions, including cold temperatures, and are a reliable choice for railways operating in such environments.

- Q:How are steel rails replaced when they become worn out?

- Steel rails are typically replaced when they become worn out by a process called rail replacement or rail renewal. This involves removing the old, worn-out rail sections and replacing them with new ones. The replacement process can vary depending on the specific circumstances, but it usually involves cutting the rail sections, removing the old rails using heavy machinery, and then installing new rails in their place. The new rails are typically secured to the track bed using fasteners such as spikes or clips, ensuring that they are firmly in place and ready for use.

- Q:Are steel rails used in other applications besides railways?

- Steel rails have diverse applications in addition to their use in railways. One notable use is in the construction industry, where they serve as a structural element for building bridges, highways, and other infrastructure projects. Due to their durability and strength, steel rails are well-suited for supporting heavy loads and enduring harsh weather conditions. Furthermore, the mining industry extensively employs steel rails, especially in underground mines. They function as tracks for mining carts, providing a dependable and efficient mode of transportation for extracting and moving minerals. Moreover, steel rails are employed in industrial settings like factories and warehouses. They can serve as tracks for overhead cranes, enabling the smooth and precise movement of heavy materials and equipment. Additionally, steel rails can occasionally be found in amusement parks, where they are utilized for rides such as roller coasters and water slides. Their robustness and ability to withstand high speeds and heavy loads make them suitable for guaranteeing the safety and stability of these attractions. In conclusion, steel rails possess a wide array of applications beyond their traditional role in railways. Their strength, durability, and dependability make them invaluable components in the construction, mining, industrial, and amusement park sectors.

- Q:What is a shaped rail?

- The rail section size adopted by railway track is different. Our country now uses four types of 75kg/m, 60kg/m, 50kg/m, 43kg/m and two types of 45kg/m and 38kg/m that have been eliminated.

- Q:How are steel rails transported to their destination?

- Steel rails are typically transported to their destination through various means such as trucks, trains, and sometimes even ships. These transportation methods ensure efficient and timely delivery of the steel rails to their desired location, whether it's a construction site or a railway station.

- Q:What are the specifications for steel rails used in high-speed rail networks?

- The specifications for steel rails used in high-speed rail networks typically include factors such as the rail's weight per unit length, its profile design, the type of steel used, and its mechanical properties. These specifications ensure that the steel rails are strong, durable, and capable of withstanding the high speeds and heavy loads associated with high-speed trains.

- Q:Can steel rails be used in areas with high temperature variations?

- Areas with high temperature variations can indeed make use of steel rails. Steel is a widely favored material for railway tracks due to its exceptional strength, durability, and ability to withstand diverse weather conditions. Steel rails possess a high melting point, enabling them to endure both scorching heat and freezing cold. They possess the remarkable capability to expand and contract according to temperature fluctuations, effectively preventing the tracks from warping or buckling. Furthermore, contemporary steel rails are often specially designed to accommodate thermal expansion and contraction, thereby enabling them to preserve their shape and structural integrity even in regions with substantial temperature variations. However, it is crucial to acknowledge that extreme temperature changes may still impact the performance of steel rails, necessitating regular maintenance and track monitoring to ensure their safe operation.

- Q:Can steel rails be used in underground or subway systems?

- Yes, steel rails can be used in underground or subway systems. In fact, steel rails are commonly used in these transportation systems due to their durability, strength, and ability to withstand heavy loads and frequent use. Additionally, steel rails provide stability and ensure smooth train movement, making them an ideal choice for underground or subway networks.

- Q:Can steel rails be used in coastal or marine environments?

- Yes, steel rails can be used in coastal or marine environments, but they require specific maintenance and protection measures to prevent corrosion. The presence of saltwater and high levels of humidity in these environments makes them susceptible to corrosion, which can weaken the rails and compromise their structural integrity. To combat this, various protective coatings are applied to steel rails in coastal or marine areas. One common method is hot-dip galvanizing, where the steel is coated with a layer of zinc that acts as a barrier against corrosive elements. This process creates a durable and long-lasting protective coating that extends the lifespan of the rails. Regular inspections and maintenance are also crucial to ensure the longevity of steel rails in coastal or marine environments. Any signs of corrosion or damage should be promptly addressed and repaired to prevent further deterioration. Additionally, the proper drainage system should be in place to minimize the accumulation of saltwater and other corrosive materials on the rails. Overall, with appropriate protective coatings, regular maintenance, and proper drainage systems, steel rails can be effectively used in coastal or marine environments, providing reliable transportation infrastructure for these areas.

1. Manufacturer Overview |

|

|---|---|

| Location | Anshan, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 650 Million |

| Main Markets | Middle East; Asia; South America; Africa; Oceania |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 50% - 70% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | Above 300,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Hot Rolled Steel Rail

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 10000MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords