Heavy Steel with High Quality for Structure Prefabricated House

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Heavy Steel with High Quality for Structure Prefabricated House:

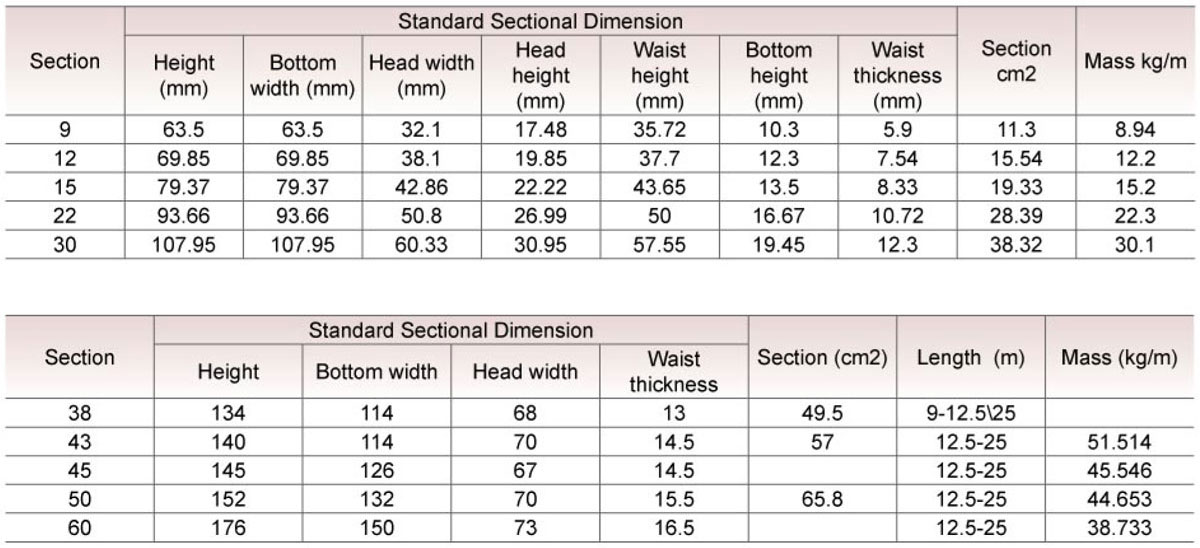

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg.

Production Standard: GB2585-81, DIN, AREMA, JIS, BS, UIC, etc.

Material: 50MN, U71MN, 900A, 110A, etc.

Length: 6m-25m according to the requriements of the clients

Usages of Heavy Steel with High Quality for Structure Prefabricated House:

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line. Be widely used for railway, subway, transportation track, express, curve way, tunnel way and so on.

Packaging & Delivery of Heavy Steel with High Quality for Structure Prefabricated House:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Heavy Steel with High Quality for Structure Prefabricated House:

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ:

Q1: What makes stainless steel stainless?

A1: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q2: Can stainless steel rust?

A2: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Q3: Why buy Materials & Equipment from OKorder.com?

A3: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Images:

- Q:How are steel rails tested for durability?

- Steel rails are tested for durability through a rigorous process that involves various methods and techniques. One common testing method is the use of ultrasonic technology. Ultrasonic waves are transmitted through the rail, and any defects or abnormalities in the rail's structure can be detected based on the reflection and absorption of these waves. This allows engineers to identify any potential weaknesses or flaws in the rail that could lead to premature failure. Another testing method used is known as the fatigue testing. This involves subjecting the steel rail to repeated loading and unloading cycles, simulating the stress and strain that the rail would experience over its expected lifespan. By monitoring the rail's response to these cycles, engineers can determine its resistance to fatigue and estimate its durability. In addition to these methods, there are also visual inspections conducted regularly. This involves visually examining the rail for any visible signs of damage, such as cracks, fractures, or corrosion. Any abnormalities observed during these inspections are further investigated and, if necessary, repaired or replaced to ensure the rail's durability. Overall, the testing of steel rails for durability is a comprehensive process involving both non-destructive testing techniques like ultrasonic testing and physical testing such as fatigue testing. These tests help to ensure that the steel rails can withstand the demanding conditions of railway operations and maintain their integrity and safety over time.

- Q:How do steel rails handle heavy axle loads?

- Steel rails are able to handle heavy axle loads due to their high strength and durability. The steel used in rail construction is specifically designed to withstand the immense pressure and weight exerted by heavy trains. Additionally, steel rails have a smooth surface and excellent dimensional stability, allowing them to distribute the weight evenly and reduce wear and tear. This enables steel rails to provide a stable and reliable track structure for heavy axle loads, ensuring safe and efficient transportation.

- Q:What is the role of rail clips in steel rail installation?

- The role of rail clips in steel rail installation is to securely fasten the rails to the sleepers or ties, ensuring stability and preventing movement or displacement under the weight of passing trains. Rail clips provide a tight grip on the rail, reducing the risk of track misalignment and maintaining the overall integrity and safety of the railway track system.

- Q:What are the different types of rail profiles used in steel rails?

- There are several different types of rail profiles used in steel rails, including the flat-bottomed rail (also known as the Vignole rail), the bullhead rail, the grooved rail, and the conductor rail. These profiles vary in shape and design to accommodate different types of railway systems and their specific requirements.

- Q:What are the safety measures for working with steel rails?

- When working with steel rails, some important safety measures to follow include wearing proper personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots. It is also essential to ensure that the work area is well-lit and free from any tripping hazards. Additionally, workers should receive proper training on handling and lifting heavy rails to prevent injuries. Regular inspections of the rails for any signs of damage or wear should also be conducted to maintain a safe working environment.

- Q:Are steel rails affected by electromagnetic interference?

- Yes, steel rails can be affected by electromagnetic interference. Electromagnetic interference can disrupt the signals and communications transmitted through the rails, potentially causing issues in railway operations. To minimize such interference, measures like grounding and shielding are often employed in rail systems.

- Q:Can steel rails be used in high-speed train systems?

- Yes, steel rails can be used in high-speed train systems. Steel rails are commonly used in high-speed train tracks due to their durability, strength, and ability to handle heavy loads. They provide a stable and reliable track foundation, ensuring smooth and safe travel at high speeds.

- Q:What are the main types of steel rails?

- The main types of steel rails are classified into three categories: light rails, heavy rails, and crane rails. Light rails are typically used in light-duty applications such as tramways and light industrial tracks. Heavy rails, on the other hand, are used for heavy-duty applications like mainline railways and high-speed tracks. Crane rails are specifically designed to withstand the heavy loads and constant movement of cranes in industrial environments.

- Q:Can steel rails be used in areas with high saline content in the soil?

- Yes, steel rails can be used in areas with high saline content in the soil. However, special precautions need to be taken to protect the steel rails from corrosion caused by the salt. This can include applying protective coatings or using corrosion-resistant materials in the construction of the rails. Regular maintenance and inspections are also necessary to ensure the longevity and safety of the steel rails in such environments.

- Q:What is the impact of steel rails on track maintenance costs?

- The impact of steel rails on track maintenance costs is significant. Steel rails are commonly used in railway tracks due to their durability and strength. They can withstand heavy loads and provide a smooth surface for trains to travel on. However, steel rails are not immune to wear and tear. Over time, steel rails can experience various forms of deterioration, such as corrosion, fatigue, and rail head wear. These issues can lead to the need for regular maintenance and eventually replacement of the rails. The cost of maintaining steel rails includes activities like rail grinding, lubrication, and periodic inspections to identify and address any defects. One of the main factors impacting track maintenance costs is the frequency of rail replacements. Steel rails have a finite lifespan, and the heavier the traffic on a railway line, the more quickly they will wear out. High-speed and heavy freight trains can put significant stress on the rails, accelerating their deterioration. Additionally, the geographic location and weather conditions can also impact maintenance costs. Areas with high humidity or proximity to the sea are prone to accelerated corrosion, requiring more frequent maintenance. Similarly, extreme temperatures and temperature fluctuations can cause rail expansion and contraction, leading to rail buckling and requiring additional maintenance efforts. Investing in high-quality steel rails with better resistance to wear and corrosion can help reduce maintenance costs in the long run. However, these rails often come at a higher upfront cost. Balancing the initial investment with the expected lifespan and maintenance requirements is crucial in determining the overall impact on track maintenance costs. Overall, while steel rails offer numerous advantages in terms of strength and durability, their maintenance costs can be significant. Regular inspections, repairs, and replacements are necessary to ensure safe and efficient railway operations. Therefore, it is crucial for railway operators to carefully consider the selection of steel rails and implement effective maintenance strategies to mitigate these costs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Heavy Steel with High Quality for Structure Prefabricated House

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords