High Quality Steel Rail

- Loading Port:

- Qingdao Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 600000MT Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

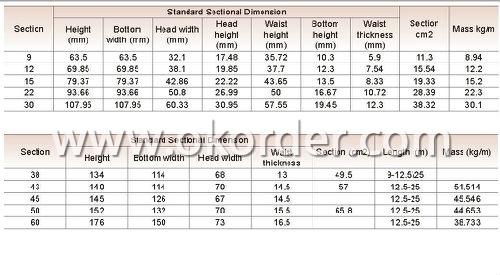

Specifications of High Quality Steel Rail

Product Name: High Quality Steel Rail

Production Standard: GB, AREMA, JIS, DIN, EN, UIC, BS, etc.

Grade: Q235B, 55Q, 900A, 1100A, 50MN, U71MN, R260.

Place of Origin: China

Length: 6M-24M according to the requriements of the customers.

Grade | Element(%) | ||||

C

| Mn | S

| P

| Si

| |

55Q

|

0.50—0.60 |

0.70—1.00 |

≤0.050 |

≤0.045

|

0.15-0.35

|

Applications of High Quality Steel Rail

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Packaging & Delivery of High Quality Steel Rail

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

7. Invoicing on theoretical weight or actual weight as customer request

8. Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Inspection of High Quality Steel Rail

We will send the MTC of the factory to the clients directly which contains the anlisis of the heat, chemiqual composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q:Can steel rails be used in railway systems with multiple signaling systems?

- Yes, steel rails can be used in railway systems with multiple signaling systems. Steel rails are commonly used in railway tracks due to their durability, strength, and reliability. They can accommodate different signaling systems, such as traditional block signaling, cab signaling, or even advanced signaling technologies like positive train control (PTC). The signaling system is typically integrated into the railway infrastructure and does not affect the compatibility of steel rails with multiple signaling systems.

- Q:What are the factors considered in determining the appropriate steel rail length for a railway line?

- The factors considered in determining the appropriate steel rail length for a railway line include the expected train speed, the weight and type of trains that will be using the line, the curvature and gradient of the track, the expected traffic volume, and the available space for the rail installation.

- Q:How do steel rails handle heavy loads and freight trains?

- Steel rails are specifically designed to handle heavy loads and freight trains. They are made from high-quality steel that has excellent strength and durability properties, enabling them to withstand the immense weight and pressure exerted by these trains. The rails are laid on a solid foundation and securely fastened to ensure stability and prevent any deformation or damage. Additionally, regular maintenance and inspections are conducted to detect any signs of wear or fatigue and promptly address them to ensure safe and efficient operation.

- Q:Can steel rails be used in coastal areas prone to saltwater exposure?

- Indeed, steel rails can be utilized in coastal regions that are susceptible to saltwater exposure; nonetheless, it is imperative to take specific precautions to guarantee their endurance and longevity in such severe surroundings. The corrosion and rusting caused by saltwater can undermine the rails and impact their performance. To alleviate the consequences of saltwater exposure, multiple measures can be implemented. One prevalent technique is the application of protective coatings onto the steel rails. These coatings act as a barrier, preventing direct contact between the steel and saltwater, thus diminishing the likelihood of corrosion. The coatings can be composed of diverse materials, including zinc, aluminum, or epoxy, and are engineered to withstand the corrosive properties of saltwater. Routine maintenance is also paramount in coastal areas prone to saltwater exposure. Periodic inspections must be conducted to identify any indications of corrosion or damage. If any issues are detected, prompt repairs or replacements should be executed to hinder further deterioration. Furthermore, suitable drainage systems should be established to minimize the accumulation of saltwater in the vicinity of the rails. This can aid in reducing the steel's exposure to saltwater and extend its lifespan. In conclusion, while steel rails can be utilized in coastal areas prone to saltwater exposure, it is crucial to implement protective measures, conduct regular maintenance, and ensure proper drainage to counteract the corrosive effects of saltwater and preserve the integrity of the rails.

- Q:What are the maintenance costs associated with steel rails?

- The maintenance costs associated with steel rails include regular inspections for wear and tear, cleaning to remove debris and prevent corrosion, lubrication to minimize friction, and occasional repairs or replacements of damaged sections.

- Q:Can steel rails be welded?

- Yes, steel rails can be welded. Welding is a commonly used method to join steel rails together, whether it is for repairs, expansion of railway tracks, or the construction of new rail lines. Welding allows for a strong and durable connection between the rails, ensuring the safety and stability of the tracks. However, it is important to note that specialized welding techniques and equipment are required for welding steel rails due to the high strength and specific requirements of the rail system.

- Q:What is the role of steel rails in providing a smooth ride for passengers?

- Steel rails play a crucial role in providing a smooth ride for passengers by providing a stable and secure track for trains to run on. The steel rails are precisely manufactured and laid to ensure they are aligned and level, minimizing any bumps or unevenness on the track. This allows the train wheels to glide smoothly along the rails, reducing vibrations and jolts that passengers may experience. Additionally, steel rails have high strength and durability, ensuring they can withstand the weight and impact of trains, further contributing to a comfortable and smooth ride for passengers.

- Q:What are the factors that can cause steel rail failure?

- There are several factors that can cause steel rail failure, including excessive wear and tear, corrosion, improper maintenance, manufacturing defects, and heavy loads. These factors can weaken the structural integrity of the rail, leading to fatigue cracks, fractures, and eventually failure.

- Q:Are steel rails resistant to wear and tear?

- Yes, steel rails are highly resistant to wear and tear.

- Q:What are the disadvantages of steel rails?

- One disadvantage of steel rails is their susceptibility to corrosion. Over time, exposure to moisture and other environmental factors can cause the steel to rust, leading to structural weakness and increased maintenance needs. Additionally, steel rails can be more expensive to manufacture and install compared to alternative materials such as concrete. They also tend to be heavier, which can result in higher transportation costs. Finally, steel rails may produce more noise and vibration, which can be disruptive to nearby residents or cause discomfort for passengers.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 1993 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Exported to Thailand, India, Brazil, Egypt, Saudi Arabia, Japan, Vietnam and many other countries and regions |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao; Rizhao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

High Quality Steel Rail

- Loading Port:

- Qingdao Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 600000MT Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords