High Quality HR Steel Rail

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25Tons m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

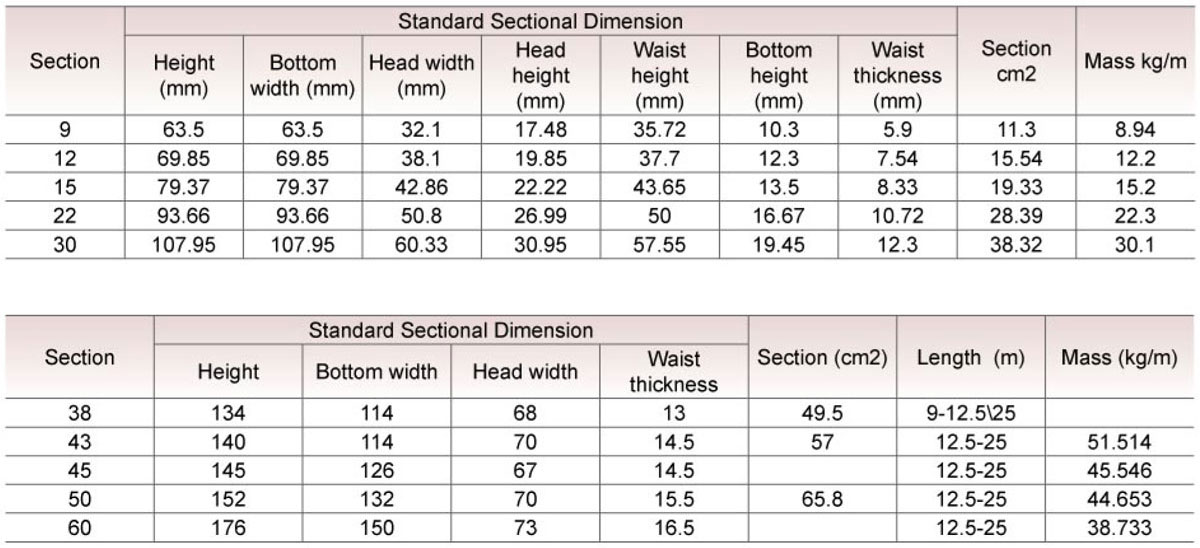

Specifications of High Quality HR Steel Rail:

Available Standard:

Light rail: GB11264-89

Heavy rail: GB2585-81

Available Material Grade:

Light rail:Q235B, 55Q

Heavy rail: 50MN, U71MN

Apllications of Steel Rail

railway

subway

transportation track

express

curve way

tunnel way

Package and Delivery of High Quality HR Steel Rail

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of High Quality HR Steel Rail

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q:Can steel rails be used for military logistics or transportation?

- Yes, steel rails can be used for military logistics or transportation. Steel rails are commonly used for the efficient movement of heavy cargo and troops over long distances, making them suitable for military purposes. The durability and strength of steel rails allow for the transportation of heavy equipment and supplies, enabling efficient military logistics operations.

- Q:Can steel rails be used in railway bridges?

- Yes, steel rails can be used in railway bridges. Steel rails are commonly used in railway tracks and bridges due to their high strength, durability, and ability to withstand heavy loads and provide stability to the structure.

- Q:What is the impact of steel rails on track alignment maintenance?

- Steel rails have a significant impact on track alignment maintenance. Due to their high strength and durability, steel rails provide stability and reduce the need for frequent realignment. Their smooth surface also ensures smoother train movements, minimizing the risk of derailments and reducing the wear and tear on the tracks. Additionally, steel rails can withstand heavy loads and harsh weather conditions, resulting in less frequent repairs and maintenance, ultimately improving the overall efficiency and safety of the railway system.

- Q:How do steel rails contribute to train noise reduction?

- There are several ways in which steel rails contribute to the reduction of train noise. Firstly, the smooth and continuous design of steel rails aids in minimizing the impact of wheels on the tracks, thereby reducing vibrations and subsequent noise. Moreover, steel rails are securely fastened to the track bed, ensuring stability and minimizing any potential rattling or shaking that may generate noise. Additionally, steel rails are often treated with various materials or coatings that absorb sound and vibrations, further decreasing noise levels. Finally, the use of steel rails allows for better control and alignment of the train, limiting unnecessary movements or disturbances that could cause increased noise. In conclusion, the design and construction of steel rails play a vital role in decreasing train noise, resulting in a more enjoyable and quieter experience for passengers and nearby residents.

- Q:How do steel rails affect train stability and balance?

- Steel rails play a crucial role in maintaining train stability and balance. The smooth and sturdy surface of steel rails allows for efficient movement of the train wheels, reducing friction and providing a stable foundation for the train to operate on. Firstly, steel rails provide a fixed path for the train to follow, ensuring that it stays on track and prevents any lateral movement. The rails are securely fastened to the sleepers or ties, which are in turn firmly anchored to the ground. This rigid structure prevents the train from swaying or derailing, especially when it encounters curves or changes in terrain. Additionally, the consistent shape and dimensions of steel rails help to distribute the weight of the train evenly across the tracks. This weight distribution is critical for maintaining balance and preventing the train from tilting or toppling over during turns or when traveling at high speeds. The rails also help to absorb and distribute the dynamic forces generated by the moving train, minimizing any oscillations or vibrations that could affect stability. Furthermore, steel rails provide a smooth and predictable surface for the train wheels to roll on. The absence of bumps or irregularities allows for a consistent contact between the wheels and the rails, reducing the risk of wheel slippage or instability. This smoothness also enables the train to maintain a steady speed and reduces the impact on passenger comfort. In conclusion, steel rails serve as a fundamental component in ensuring train stability and balance. Their strong and fixed structure, along with their ability to distribute weight and provide a smooth surface, contribute to the safe and efficient operation of trains.

- Q:What is the cost of steel rails?

- The cost of steel rails can vary depending on various factors such as the quantity, quality, market conditions, and specific requirements. It is best to consult with steel rail suppliers or manufacturers for accurate and up-to-date pricing information.

- Q:How do steel rails contribute to reducing track settlement issues?

- There are several ways in which steel rails contribute to the reduction of track settlement issues. To begin with, steel rails possess greater strength and rigidity compared to other rail track materials like wooden sleepers. This strength and rigidity assist in evenly distributing the weight of trains along the track, thereby preventing excessive pressure on specific points and decreasing the chances of settlement. Furthermore, steel rails are designed to be highly durable and resistant to wear and tear. Consequently, they can maintain their shape and structure for extended periods, even when subjected to heavy train traffic. Consequently, they are less susceptible to deformation or sinking into the ground, which can result in track settlement. Moreover, steel rails are typically installed on well-engineered ballast beds. These ballasts provide a stable and supportive foundation for the rails, aiding in the even distribution of the load and mitigating settlement. Additionally, the ballast facilitates proper drainage, reducing the risk of water accumulation and subsequent softening of the ground beneath the track. In addition, regular inspections and maintenance are conducted on steel rails to ensure their integrity. Any signs of settlement or deformation are promptly identified and addressed, preventing further track settlement issues from arising. Overall, the utilization of steel rails in rail tracks significantly reduces the likelihood of track settlement problems due to their strength, durability, and the presence of supporting ballast beds. This, in turn, guarantees the long-term stability and safety of the railway infrastructure.

- Q:What is the role of ballast in supporting steel rails?

- The role of ballast in supporting steel rails is to provide stability and distribute the weight of the rails and trains evenly across the track. It helps to prevent the rails from sinking into the ground or shifting under the weight of passing trains, ensuring a safe and reliable track structure.

- Q:What is the average density of steel rails?

- The average density of steel rails is around 7.8 grams per cubic centimeter.

- Q:Can steel rails be used in tunnels with limited ventilation?

- Yes, steel rails can be used in tunnels with limited ventilation. Steel rails are commonly used in tunnels for various transportation systems, including trains and subways. They are chosen for their durability, strength, and ability to withstand heavy loads. While tunnels with limited ventilation may pose challenges in terms of air quality and heat dissipation, proper engineering and design considerations can help mitigate these issues. For example, ventilation systems can be installed to ensure sufficient airflow and prevent the build-up of harmful gases. Additionally, heat-resistant materials can be used to minimize the impact of high temperatures. Overall, while limited ventilation may require additional measures, steel rails can still be safely and effectively used in tunnels.

1. Manufacturer Overview |

|

|---|---|

| Location | Anshan, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 650 Million |

| Main Markets | Middle East; Asia; South America; Africa; Oceania |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 50% - 70% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | Above 300,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality HR Steel Rail

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25Tons m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords