Steel Rail, Hot Rolled, GB, DIN, AREMA, JIS, BS, UIC for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

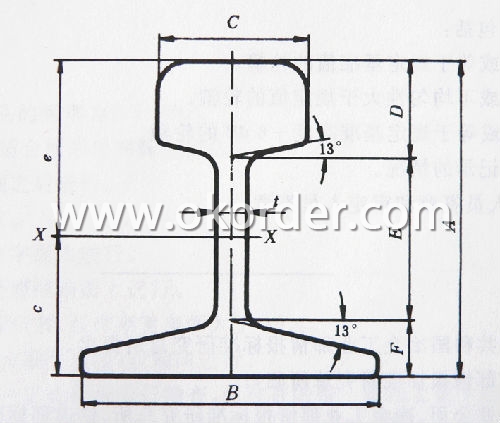

Product Description of Steel Rail, Hot Rolled, GB, DIN, AREMA, JIS, BS, UIC for Sale:

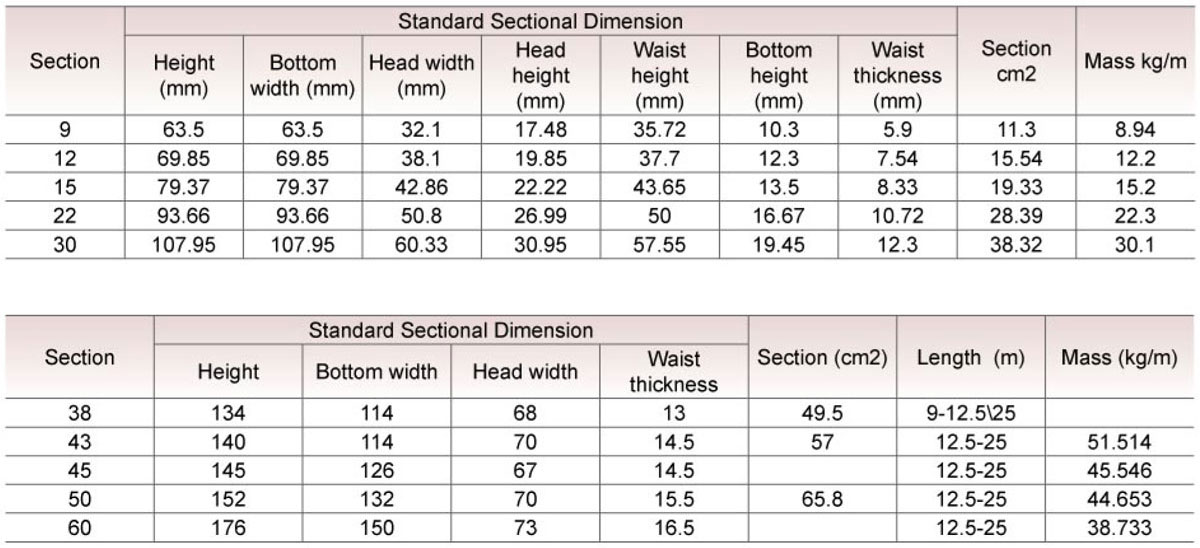

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg.

Production Standard: GB2585-81, DIN, AREMA, JIS, BS, UIC, etc.

Material: 50MN, U71MN, 900A, 110A, etc.

Length: 6m-25m according to the requriements of the clients

Usages of Steel Rail, Hot Rolled, GB, DIN, AREMA, JIS, BS, UIC for Sale:

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line. Be widely used for railway, subway, transportation track, express, curve way, tunnel way and so on.

Packaging & Delivery of Steel Rail, Hot Rolled, GB, DIN, AREMA, JIS, BS, UIC for Sale:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Steel Rail, Hot Rolled, GB, DIN, AREMA, JIS, BS, UIC for Sale:

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q3: Can stainless steel rust?

A3: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q:What are the safety measures taken during steel rail installation and maintenance?

- During steel rail installation and maintenance, several safety measures are taken to ensure the well-being of workers and the general public. These measures include proper training and certification for workers, the use of personal protective equipment (PPE) such as helmets, gloves, and safety glasses, the implementation of safety protocols and procedures, regular inspections of equipment and tools, and the establishment of clear communication channels between workers. Additionally, safety barriers and warning signs are often employed to prevent unauthorized access to work areas and to alert people of potential hazards. Regular maintenance and repairs are also crucial to maintain the integrity and safety of steel rails, preventing accidents and ensuring the smooth operation of rail systems.

- Q:What is the process of replacing damaged steel rails in emergency situations?

- In emergency situations, the process of replacing damaged steel rails typically involves a series of steps. Firstly, the damaged section of the rail is identified and marked for replacement. Next, the rail is cut and removed using specialized tools and equipment. Simultaneously, any broken or weakened rail fastenings are replaced to ensure proper stability. Once the damaged rail is removed, a new rail section is prepared and aligned with the existing track. This involves ensuring the correct length and alignment to maintain the integrity of the rail line. The new rail is then securely fastened to the track using bolts or other appropriate fastening methods. Finally, the track is inspected and tested to ensure it is safe for train operations before it is reopened for use.

- Q:How are steel rails recycled at the end of their lifespan?

- Steel rails are recycled at the end of their lifespan through a process known as rail reclamation or rail recycling. This process involves several steps to ensure that the steel rails are properly reused and do not end up in landfills. Firstly, the steel rails are carefully removed from the tracks using specialized equipment. This can involve cutting the rails into smaller sections for easier transportation. Once the rails are removed, they are inspected for any defects or damages. Rails that are in good condition can be refurbished and reused in various applications such as railroads, construction projects, or even as decorative pieces. If the rails are not suitable for reuse, they are then sent to a steel mill for recycling. At the mill, the rails are shredded into small pieces and then melted down in a furnace. This process helps to separate the steel from any impurities or contaminants. The melted steel is then formed into new steel products, such as beams, bars, or even new steel rails. This recycled steel can be used in a wide range of industries, reducing the need for raw materials and conserving energy in the production process. Overall, the recycling of steel rails at the end of their lifespan provides both environmental and economic benefits. It helps to reduce waste and conserve resources, while also supporting a sustainable and circular economy.

- Q:What are the benefits of using steel rails in high-speed train systems?

- Using steel rails in high-speed train systems offers several advantages. Firstly, steel rails are highly durable and strong, enabling them to withstand the heavy loads and stresses associated with high-speed trains. Their resistance to wear and tear ensures a longer lifespan compared to other materials, resulting in cost savings for train operators. Secondly, steel rails provide superior stability and track alignment, essential for safe and efficient train operations. The smooth surface reduces friction and resistance, allowing trains to travel at high speeds with minimal energy loss. This enhances overall speed and performance while reducing energy consumption and carbon emissions. Moreover, steel rails maintain precise alignment, providing a smooth and comfortable ride for passengers by minimizing vibrations and noise levels. They also resist deformation, preventing track irregularities that could lead to disruptions or accidents. Additionally, steel rails are compatible with advanced signaling and train control systems, facilitating precise and efficient train operations. Effective communication between trains and track infrastructure is enabled by the steel material, enhancing high-speed train control and monitoring. Lastly, the worldwide success of steel rails in high-speed train systems, seen in countries like Japan, China, and France, makes them a reliable and trusted choice for new projects. The experience gained from these systems makes steel rails essential for ensuring the safe, efficient, and reliable operation of high-speed trains. In conclusion, the benefits of using steel rails in high-speed train systems include durability, stability, energy efficiency, passenger comfort, track geometry control, and compatibility with advanced train control systems. These advantages make steel rails an essential component in ensuring the safe, efficient, and reliable operation of high-speed trains.

- Q:Can steel rails be used in curved track sections?

- Yes, steel rails can be used in curved track sections.

- Q:Can steel rails be used in railway systems with multiple tracks?

- Yes, steel rails can be used in railway systems with multiple tracks. Steel rails are commonly used in railway systems worldwide due to their durability, strength, and ability to support heavy loads. In railway systems with multiple tracks, steel rails are laid parallel to each other, providing a stable and reliable foundation for trains to travel on. The tracks are typically spaced apart to accommodate multiple tracks, allowing for the operation of multiple trains simultaneously. Steel rails are designed to withstand the weight and impact of trains, ensuring safe and efficient transportation across multiple tracks in railway systems.

- Q:How do steel rails contribute to the safety of railway tracks?

- Steel rails contribute to the safety of railway tracks by providing a sturdy and durable foundation for trains to travel on. Their strength and resilience help support the weight of trains and maintain the track alignment, reducing the risk of derailments. Additionally, steel rails offer excellent traction, allowing trains to brake and accelerate efficiently. Their smooth surface reduces friction and wear, minimizing the chances of accidents caused by excessive heat or track degradation. Overall, steel rails play a crucial role in ensuring the safe and reliable operation of railway tracks.

- Q:How are steel rails insulated for third rail electrification?

- Steel rails used for third rail electrification are insulated through a process called rail bonding. Rail bonding involves the installation of insulating materials between the steel rails and the third rail, which carries the electrical current. The insulating materials can be in the form of insulating pads or insulating boots. Insulating pads are typically made of rubber or other high-dielectric materials. They are placed between the steel rails and the third rail at regular intervals along the track. These pads prevent direct electrical contact between the third rail and the steel rails, effectively isolating the electric current. Insulating boots, on the other hand, are used at the joints between rail sections. These boots are made of insulating materials and are placed around the joint area to prevent the electrical current from flowing between the rails. In addition to insulating pads and boots, other measures are also taken to ensure proper insulation. Bonding wires are used to connect the steel rails on either side of the insulating pads or boots, creating a continuous electrical path. This helps to maintain electrical continuity and prevent the buildup of electrical potential across the insulating materials. Regular maintenance and inspection of the insulating materials are crucial to ensure their effectiveness. Any signs of wear, damage, or degradation in the insulating pads or boots should be promptly addressed to maintain the electrical insulation between the steel rails and the third rail. Overall, the insulation of steel rails for third rail electrification is vital to ensure safe and efficient operation of electric trains. Proper insulation prevents electrical leakage and minimizes the risk of electrical shocks to personnel and damage to equipment.

- Q:How do steel rails handle uneven track settlements?

- Steel rails are designed to handle uneven track settlements by flexing and adjusting to the changes in the track alignment. The flexibility of steel allows it to absorb the impact and distribute the load evenly, minimizing the effects of settlement on the train's stability and smoothness of the ride. Additionally, regular maintenance and monitoring of the tracks help identify and rectify any settlement issues promptly, ensuring safe and efficient rail operations.

- Q:Are there any alternative materials to steel for railway tracks?

- Yes, there are alternative materials to steel for railway tracks. Some of the alternatives include concrete, composite materials, and hybrid systems. These materials offer benefits such as reduced maintenance, increased durability, and improved noise reduction. However, their suitability depends on various factors such as the specific requirements of the railway system and the environmental conditions in which they will be used.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Rail, Hot Rolled, GB, DIN, AREMA, JIS, BS, UIC for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords