Light Rail

- Loading Port:

- Qingdao Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Light Rail

Production Standard: GB 11264-89, DIN, AREMA, JIS, BS, UIC, etc.

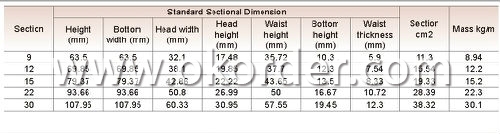

Sizes: 9kg, 12kg, 15kg, 22kg, 30kg

Length: 6m-25m according to the requriements of the clients

Material: Q235B, 55Q, 900A, etc.

Alloy No | Grade | Element(%) | ||||

C

| Mn | S

| P

| Si

| ||

Q235 |

B

|

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045

|

≤0.3

|

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Usages of Light Rail

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line. Be widely used for railway, subway, transportation track, express, curve way, tunnel way and so on.

Packaging & Delivery of Light Rail

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Light Rail

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q:What are the different types of rail sleepers used with steel rails?

- There exist various rail sleepers utilized alongside steel rails, each possessing unique characteristics and advantages. 1. Wooden Sleepers: Known as timber sleepers, wooden sleepers have enjoyed widespread usage in rail construction for numerous years. Crafted from treated hardwood or softwood, they offer commendable insulation and resistance to decay. Wooden sleepers are relatively cost-effective and simple to install, making them a favored option in many railway systems. 2. Concrete Sleepers: Also referred to as concrete ties, concrete sleepers represent another commonly employed type of sleeper. Created from pre-stressed concrete, they boast exceptional durability and long-lasting performance. Although pricier than wooden sleepers, concrete sleepers provide heightened stability and load-bearing capacity, rendering them suitable for high-speed and heavy traffic railways. 3. Steel Sleepers: Sometimes called steel ties, steel sleepers consist entirely of steel. They possess incredible strength and durability, capable of withstanding heavy loads and high-speed train operations. Steel sleepers are often utilized in regions with extreme weather conditions or concerns about vandalism, as they resist rot, fire, and theft. 4. Composite Sleepers: Also known as plastic sleepers or synthetic sleepers, composite sleepers represent a more recent advancement in rail sleeper technology. Comprising a blend of plastic materials, such as recycled plastics or fiberglass, they offer a lightweight and environmentally friendly substitute for traditional sleepers. Composite sleepers provide commendable insulation, corrosion resistance, and low maintenance requirements. 5. Prestressed Concrete Sleepers: Prestressed concrete sleepers represent a specialized variation of concrete sleepers that incorporate steel wires or rods within the concrete structure. These steel reinforcements enhance the sleeper's strength and flexibility, minimizing the risk of cracking or deformation under heavy loads. Prestressed concrete sleepers are commonly employed in high-speed railways and regions with challenging terrain. Each type of rail sleeper possesses its own set of advantages and disadvantages. The choice of sleeper will depend on factors such as the requirements of the railway system, budget constraints, and environmental conditions.

- Q:How are steel rails insulated for electrical safety?

- Steel rails are not typically insulated for electrical safety. Instead, electrical safety measures are implemented through the use of other components such as insulators, bonding wires, and grounding systems. These elements are designed to prevent electrical currents from flowing through the steel rails, thus ensuring the safety of railway operations.

- Q:What are the challenges faced in maintaining steel rails in extreme weather conditions?

- One of the main challenges in maintaining steel rails in extreme weather conditions is the susceptibility to corrosion. In extremely cold weather, for example, the expansion and contraction of the rail can lead to cracks and breaks, while in hot weather, the rails can expand and buckle. Heavy rainfall and snowfall can also cause erosion and damage to the rails, making them more prone to wear and tear. Additionally, extreme temperatures can affect the integrity of the rail bed and the stability of the track, requiring frequent inspections and repairs to ensure safe and efficient train operations.

- Q:Are steel rails susceptible to warping or bending?

- Yes, steel rails can be susceptible to warping or bending under certain conditions such as extreme heat, heavy loads, or improper maintenance. However, proper design, quality control, and regular maintenance can help minimize these risks.

- Q:How do steel rails handle wear and tear?

- Steel rails are designed to handle wear and tear efficiently. The high strength and durability of steel allow rails to withstand heavy loads, constant train traffic, and environmental factors without significant degradation. Regular maintenance and inspections help to identify and address any wear and tear, ensuring the long-term performance and safety of steel rails.

- Q:What are the different sizes of steel rails available?

- The different sizes of steel rails available vary depending on the specific requirements and applications. Common sizes range from 30 pounds per yard (15 kg/m) to 175 pounds per yard (87 kg/m) or even higher for specialized applications. These sizes are determined by factors such as the weight-bearing capacity, track gauge, and intended usage of the rail.

- Q:What are the safety regulations and standards for steel rail manufacturing and installation?

- The safety regulations and standards for steel rail manufacturing and installation vary depending on the country and specific industry guidelines. However, some common safety measures include adherence to established manufacturing processes, quality control checks, and compliance with international standards such as ISO 9001. Installation safety regulations involve proper alignment, secure fastening, and regular inspections to identify any defects or potential hazards. Additionally, safety protocols may also include employee training, personal protective equipment requirements, and adherence to local occupational health and safety regulations.

- Q:How are steel rails tested for strength?

- Steel rails are tested for strength through a process called rail fatigue testing. This involves subjecting the rails to repeated loading and unloading cycles to simulate the stress they experience during train operations. The rails are typically placed on a testing machine that applies varying loads and measures the resulting deflection and stress. By analyzing this data, engineers can determine the strength and durability of the steel rails.

- Q:Are steel rails recyclable?

- Yes, steel rails are recyclable. Steel is a highly recyclable material, and steel rails can be melted down and reused to produce new steel products. Recycling steel rails not only helps conserve natural resources but also reduces the environmental impact associated with the production of new steel.

- Q:How do steel rails handle electromagnetic interference?

- Steel rails are effective at handling electromagnetic interference due to their high electrical conductivity. The steel material acts as a shield, dissipating and redirecting electromagnetic waves away from the rail system, thus minimizing the potential for interference with signals or communication systems.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 1993 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Exported to Thailand, India, Brazil, Egypt, Saudi Arabia, Japan, Vietnam and many other countries and regions |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao; Rizhao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Light Rail

- Loading Port:

- Qingdao Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords