Steel Heavy Rail

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Steel Heavy Rail

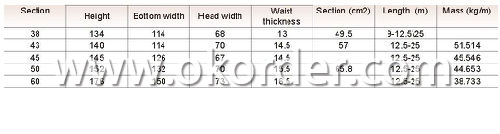

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg.

Production Standard: GB2585-81, DIN, AREMA, JIS, BS, UIC, etc.

Material: 50MN, U71MN, 900A, 110A, etc.

Length: 6m-25m according to the requriements of the clients

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Applications of Steel Heavy Rail

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Tunnel way, curve way, railway, subway, transportation track, express, etc.

Package & Delivery of Steel Heavy Rail

1. Package: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, size, length, grade, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Steel Heavy Rail

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

Production flow of Steel Heavy Rail

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q:What is the impact of steel rails on train suspension systems?

- Steel rails have a significant impact on train suspension systems. The smooth surface and high strength of steel rails allow for efficient and stable movement of trains, reducing vibrations and providing a smoother ride for passengers. Additionally, steel rails distribute the weight of the train evenly, minimizing stress on the suspension components and enhancing overall safety and durability of the system.

- Q:Can steel rails be used in urban metro systems?

- Yes, steel rails can be used in urban metro systems. Steel rails are commonly used in metro systems due to their durability, strength, and ability to withstand heavy loads and high-speed trains. They provide a stable and reliable track for the metro trains, ensuring safe and efficient transportation within urban areas.

- Q:How are steel rails protected against chemical exposures?

- Steel rails are protected against chemical exposures through the application of protective coatings. These coatings act as a barrier, preventing chemical substances from coming into direct contact with the steel surface. This helps to minimize the risk of corrosion and deterioration, ensuring the longevity and durability of the steel rails.

- Q:What are the different types of steel rail switches?

- There are several types of steel rail switches, including the common single-point switch, double slip switch, movable point frog, and three-way switch. Each type has its own design and functionality, allowing for efficient and safe switching of trains onto different tracks.

- Q:What is the role of ballast in steel rail tracks?

- The role of ballast in steel rail tracks is to provide stability and support to the tracks by distributing the weight of the trains evenly. It helps to prevent shifting and settling of the tracks, reduces vibrations and noise, and improves the overall performance and lifespan of the railway infrastructure.

- Q:What is the difference between steel rails and other rail materials?

- Steel rails, widely used in various industries, especially construction and transportation, stand out from other rail materials in terms of their composition, durability, and performance. Firstly, steel rails are composed of a combination of iron and carbon, along with additional elements like manganese, silicon, and trace metals, which enhance their strength, hardness, and resistance to wear. This differs from materials such as wood, concrete, or composites, which have varying compositions and properties that may not be suitable for heavy-duty purposes. Secondly, the durability of steel rails is noteworthy. Their robust construction allows them to endure heavy loads, frequent usage, and adverse weather conditions without significant damage. They resist bending, cracking, and warping, resulting in a longer lifespan compared to other materials. Conversely, wood may rot, concrete may crack, and composites may degrade over time, requiring more frequent maintenance and replacement. Additionally, steel rails offer excellent performance characteristics. They provide a smooth and stable track, ensuring dimensional accuracy for trains, trams, and other vehicles. With a low friction coefficient, they enable efficient movement and reduced energy consumption. Steel rails also minimize vibrations and noise, providing a smoother and quieter ride for passengers. Other rail materials may not possess these performance qualities to the same extent. Moreover, steel rails seamlessly integrate with various track systems and can be easily adapted to existing infrastructure. Their versatility allows for customization and adaptation to different track layouts, making them the preferred choice for railways, subways, and other transportation networks. To summarize, steel rails differ from other rail materials due to their composition, durability, and performance characteristics. Their robust construction, long lifespan, and excellent performance make them a reliable and cost-effective option for heavy-duty rail applications.

- Q:What are the common challenges in replacing steel rails?

- Some common challenges in replacing steel rails include the high cost of materials and labor, the need for specialized equipment and expertise, the disruption to train schedules and transportation systems during the replacement process, and the potential for logistical issues such as limited access to rail lines and the coordination of multiple stakeholders involved in the replacement project.

- Q:Do steel rails require regular lubrication?

- No, steel rails do not require regular lubrication.

- Q:How are rail fractures repaired?

- Rail fractures are repaired by cutting out the damaged section of the rail and replacing it with a new piece. The process involves grinding the ends of the remaining rail to ensure a smooth fit, welding the new piece in place, and conducting thorough inspections to ensure the repair is sturdy and safe for train operations.

- Q:How do steel rails handle electromagnetic interference?

- Steel rails are effective at handling electromagnetic interference due to their high electrical conductivity. The steel material acts as a shield, dissipating and redirecting electromagnetic waves away from the rail system, thus minimizing the potential for interference with signals or communication systems.

1. Manufacturer Overview |

|

|---|---|

| Location | Anshan, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 650 Million |

| Main Markets | Middle East; Asia; South America; Africa; Oceania |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 50% - 70% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | Above 300,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Steel Heavy Rail

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords