Hot Rolled Light Steel Rail with High Quality 55Q

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Hot Rolled Light Steel Rail with High Quality 55Q at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Light Steel Rail with High Quality 55Q is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Product Advantages:

OKorder's Hot Rolled Light Steel Rail with High Quality 55Q are durable, strong, and with competitive price

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 25m, as per customer request

Packaging: Export packing, nude packing, bundled

Production Standard: GB 11264-89, GB2585-81, AREMA2008, JIS, DIN536, EN13674-1-2003, etc.

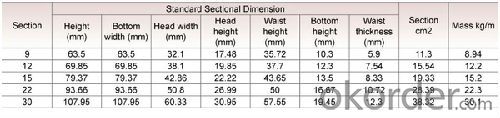

Sizes: 9kg-60kg

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4:What is the package

A4: Standard seaworthy packing or as customer required; all goods are packed in bundle with steel strips and shipped by break bulk vessel or container

Images:

.

- Q:Are steel rails used in tram tracks?

- Yes, steel rails are commonly used in tram tracks due to their durability and ability to withstand heavy loads and frequent use.

- Q:How are steel rails replaced when they wear out?

- Steel rails are typically replaced when they wear out by first detaching the old rails from the railway track. This is done by unbolting them from the sleepers or ties that support them. Once the old rails are removed, new rails are installed in their place. The new rails are carefully aligned and bolted securely to the sleepers/ties, ensuring proper alignment and stability. The process may involve using heavy machinery, such as cranes and rail installation equipment, to lift and position the new rails accurately.

- Q:What are the factors that determine the lifespan of steel rails?

- The lifespan of steel rails is determined by several factors, including the quality of the steel used in their construction, the level of maintenance and inspection they receive, the operating conditions and loads they are subjected to, and the presence of any environmental factors that can accelerate deterioration. Firstly, the quality of the steel used in manufacturing the rails plays a crucial role in determining their lifespan. High-quality steel with the right composition and properties will generally have better resistance to wear, fatigue, and corrosion, ensuring a longer lifespan. Secondly, the level of maintenance and inspection that the steel rails receive is essential. Regular inspection and maintenance can help detect and address any issues promptly, such as cracks, deformations, or corrosion. Timely repairs and replacements can significantly extend the lifespan of the rails by preventing further damage and ensuring their structural integrity. Thirdly, the operating conditions and loads to which the steel rails are exposed greatly impact their lifespan. Heavy traffic volumes, high-speed trains, and heavy loads can accelerate wear and fatigue on the rails, leading to a shorter lifespan. Proper design and construction of the rail infrastructure, such as using appropriate rail profiles and ensuring adequate support and alignment, can help mitigate these factors and increase the lifespan of the rails. Lastly, environmental factors can also influence the lifespan of steel rails. Exposure to harsh weather conditions, such as extreme temperatures, moisture, or chemical pollutants, can lead to corrosion and accelerated deterioration. Proper protective coatings, regular cleaning, and appropriate drainage systems can help mitigate these environmental factors and prolong the lifespan of the rails. In conclusion, the lifespan of steel rails is determined by the quality of the steel, the level of maintenance and inspection, the operating conditions and loads, and environmental factors. By addressing these factors appropriately, railway operators can ensure the longevity and safety of their steel rail infrastructure.

- Q:What is the impact of heavy traffic on steel rails?

- Steel rails can be significantly affected by heavy traffic. Firstly, the constant weight and pressure exerted by heavy vehicles passing over the rails can result in excessive wear and tear. This can lead to the formation of ruts, which in turn can cause train wheels to become misaligned and raise the risk of derailments. Moreover, vibrations and shocks caused by heavy traffic can exacerbate the deterioration of the steel rails. These vibrations can gradually weaken the rails over time, leading to the development of cracks or fractures that compromise their structural integrity. Consequently, this poses a serious safety hazard for trains and necessitates frequent maintenance and repairs. Additionally, heavy traffic can contribute to noise pollution and vibrations in nearby residential areas, thereby impacting the quality of life for those residing near rail tracks. In summary, heavy traffic speeds up the degradation of steel rails, escalating safety risks, maintenance expenses, and inconveniences for both rail operators and neighboring communities.

- Q:What are the average installation timelines for steel rails?

- The average installation timelines for steel rails can vary depending on various factors such as the length of the rail track, the complexity of the terrain, the availability of resources, and the efficiency of the construction team. Generally, for a straightforward installation of steel rails on a relatively flat terrain, the process can take anywhere from a few days to a couple of weeks. This includes activities such as marking out the track, preparing the site, laying the foundation, and finally installing the rails. However, for more complex rail projects that involve challenging terrains or require extensive earthwork, the installation timelines can be significantly longer. In such cases, it may take several weeks or even months to complete the installation process. It is important to note that the installation timelines can also be affected by external factors such as weather conditions, permits and approvals, and any unforeseen challenges that may arise during the construction process. Therefore, it is recommended to consult with experienced professionals and project managers who can assess the specific requirements of the rail installation project and provide a more accurate timeline based on the specific circumstances.

- Q:How are steel rails protected against warping?

- Steel rails are protected against warping through a process called stress relieving. This involves heating the rails to a specific temperature and then slowly cooling them, which helps to relieve any internal stresses and prevent warping. Additionally, proper installation and maintenance practices such as correct alignment and regular inspections also contribute to ensuring that steel rails remain resistant to warping.

- Q:How are steel rails protected from damage caused by rockslides?

- Steel rails are protected from damage caused by rockslides through various measures, including the use of protective barriers and rock catchment systems. These barriers are designed to deflect or absorb the impact of falling rocks, preventing them from directly hitting the rails. Additionally, rock catchment systems are installed to divert falling rocks away from the track, ensuring that they do not cause any harm. Regular maintenance and inspection of the tracks also play a crucial role in identifying and addressing any potential damage caused by rockslides in a timely manner.

- Q:What are the different types of rail fastening clips used with steel rails?

- There are several types of rail fastening clips used with steel rails, including elastic rail clips, SKL clips, PR clips, and KPO clips. These clips are designed to secure the rails to the sleepers or ties, providing stability and ensuring proper alignment of the track. Each type of clip has its own unique design and features, but they all serve the same purpose of holding the rails firmly in place to maintain the integrity of the railway system.

- Q:How do steel rails contribute to the overall cost of a railway project?

- Steel rails contribute significantly to the overall cost of a railway project due to their high material and manufacturing costs, as well as the extensive amount of rails required for the entire track. Additionally, ongoing maintenance and replacement costs for steel rails throughout the lifespan of the railway further add to the project's overall expenses.

- Q:Can steel rails be customized for specific track requirements?

- Yes, steel rails can be customized for specific track requirements. Different tracks may have varying needs such as weight capacity, durability, and resistance to wear and tear. Steel rails can be modified in terms of size, shape, and composition to meet these specific requirements and ensure optimal performance and safety for the track.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Light Steel Rail with High Quality 55Q

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords