Ms Light Steel Rail Q235, 55Q

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25Tons m.t.

- Supply Capability:

- 10000Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Ms Light Steel Rail Q235, 55Q

Production Standard: GB11264-89

Material: Q235, 55Q

Grade | Element(%) | ||||

C | Mn | S

| P

| Si

| |

Q235 |

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045

|

≤0.3

|

55Q | 0.50—0.60 | 0.70—1.00 | ≤0.050 | ≤0.045 | 0.15-0.35 |

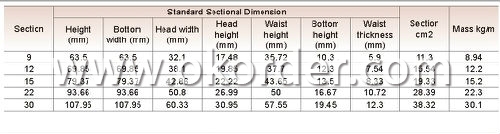

Sizes: 9kg, 12kg, 15kg, 22kg, 30kg

Length: 6M, 8M, 10M, 12M or as the requriement

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Applications of Ms Light Steel Rail Q235, 55Q

Light Steel Rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line, for example:

railway, subway, transportation track, express, curve way, tunnel way.

Package & Delivery of Ms Light Steel Rail Q235, 55Q

1. Package: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Production flow of Ms Light Steel Rail Q235, 55Q

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

Inspection of Ms Light Steel Rail Q235, 55Q

We will send the MTC of the factory to the clients directly which contains the anlisis of the heat, chemiqual composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q:What are the requirements for steel rail storage and handling?

- The requirements for steel rail storage and handling can vary depending on the specific circumstances and industry standards. However, there are some general requirements that are typically followed to ensure the safety and proper handling of steel rails. 1. Storage Space: Adequate storage space is required for steel rail storage. The area should be clear of any debris or obstructions and should have a solid, flat surface to prevent any bending or damage to the rails. The rails should be properly stacked with sufficient clearance between each layer to prevent any distortion or bending. 2. Environmental Conditions: Steel rails should be stored in a dry, well-ventilated area to protect them from moisture and humidity. Excessive exposure to moisture can lead to rust and corrosion, which can weaken the rails over time. It is also important to protect the rails from extreme temperatures and direct sunlight, as this can cause expansion or contraction and affect their structural integrity. 3. Handling Equipment: The use of appropriate handling equipment is essential to ensure the safe transportation and storage of steel rails. This may include cranes, forklifts, or railcar movers, depending on the size and weight of the rails. The equipment should be properly maintained and operated by trained personnel to prevent accidents and damage to the rails. 4. Handling Techniques: When handling steel rails, it is important to use proper lifting techniques to prevent any bending or distortion. The rails should be lifted evenly and supported throughout their length to avoid any stress concentration points. Additionally, sharp or pointed objects should be kept away from the rails to prevent scratching or gouging. 5. Marking and Identification: Each steel rail should be properly marked and identified to ensure traceability and easy identification. This may include markings such as the rail type, size, and manufacturer's information. Proper labeling and documentation are essential for inventory management and quality control purposes. 6. Inspection and Maintenance: Regular inspection and maintenance of steel rails are crucial to identify any signs of damage, wear, or corrosion. Any rails that do not meet the required standards or show signs of defect should be removed from service and replaced promptly. Overall, the requirements for steel rail storage and handling involve creating a safe and suitable environment, using proper equipment and techniques, and ensuring regular inspection and maintenance. Following these requirements helps to prolong the lifespan of the rails, maintain their structural integrity, and prevent accidents or damage during storage and transportation.

- Q:How do steel rails handle the weight distribution of trains?

- Steel rails are designed to handle the weight distribution of trains by providing a strong and durable surface for the wheels to roll on. The rails are made from high-strength steel that can withstand the heavy loads of trains and distribute the weight evenly across the track. Additionally, the rails are laid on a stable foundation to ensure proper weight distribution and prevent any deformities or failures.

- Q:How are steel rails affected by extreme weather conditions?

- Steel rails can be affected by extreme weather conditions in various ways. For instance, during hot weather, steel rails can expand, causing them to buckle or warp. In cold weather, they can contract and become more brittle, potentially leading to cracks or fractures. Additionally, extreme weather conditions such as heavy rain, snow, or ice can corrode the rails, compromising their strength and integrity. Thus, it is crucial to regularly inspect and maintain steel rails to ensure safe and efficient railway operations in all weather conditions.

- Q:How are steel rails inspected for fatigue cracks?

- Steel rails are inspected for fatigue cracks using a variety of non-destructive testing methods such as ultrasonic testing, magnetic particle inspection, and visual inspection. These techniques allow for a thorough examination of the rail's surface and subsurface, enabling early detection and prevention of potential cracks that could compromise safety.

- Q:How do steel rails contribute to the smoothness of train rides?

- Steel rails contribute to the smoothness of train rides primarily by providing a stable and durable track structure. The high strength and stiffness of steel rails help to distribute the weight of the train evenly, reducing vibrations and minimizing the impact on passengers. Additionally, the precision manufacturing of steel rails ensures a consistent and level track surface, allowing trains to travel smoothly without jolts or bumps.

- Q:Are steel rails affected by changes in track gauge or width?

- Yes, steel rails are affected by changes in track gauge or width. The gauge or width of a track refers to the distance between the inner sides of the rails. Steel rails are designed to fit specific track gauges and widths, so any changes in these dimensions can impact the compatibility and functionality of the rails.

- Q:How are steel rails protected from theft and vandalism?

- Steel rails are protected from theft and vandalism through various security measures and precautions. These include regular patrols and surveillance of railway tracks by security personnel, installation of CCTV cameras at vulnerable points, fencing and secure enclosures around rail yards, and the use of tamper-proof fasteners and locks. Additionally, marking and tracking systems are often employed to deter theft and aid in the recovery of stolen rails.

- Q:What is the impact of high-speed trains on steel rails?

- Steel rails are greatly affected by high-speed trains because of the immense forces and stresses they generate. The high speeds at which these trains operate result in increased wear and tear on the steel rails, requiring regular maintenance and replacement. The main impact of high-speed trains on steel rails is the occurrence of wear and fatigue. The weight and speed of these trains exert tremendous pressure on the rails, causing them to gradually wear down over time. This wear is typically seen in metal loss, surface deformation, and rail head damage. The constant friction between the train's wheels and the rails generates heat, further contributing to the degradation of the steel rails. To reduce the impact of high-speed trains, steel rails are made from materials that are strong and resistant to wear. These materials are specifically designed to withstand the immense forces exerted by the trains and have a longer service life. Additionally, the rails are regularly inspected and maintained to identify any signs of wear or damage and prevent potential accidents. The impact of high-speed trains on steel rails also affects the design and construction of the railway infrastructure. The tracks need to be built in a way that can accommodate higher speeds, with reinforced foundations and specialized rail fastening systems. This additional investment in infrastructure is necessary to ensure the safety and reliability of the railway system. Despite the challenges posed by high-speed trains, they also bring certain advantages to steel rails. The increased use of railways for high-speed transportation leads to a higher demand for steel rails, which stimulates the steel industry and supports economic growth. Furthermore, the technological advancements in rail engineering driven by high-speed trains can result in improvements in rail materials and designs, benefiting not only high-speed rail systems but also conventional rail networks. In conclusion, the impact of high-speed trains on steel rails is significant. The wear and fatigue caused by the immense forces and speeds of these trains require regular maintenance and replacement of the rails. However, this impact also drives advancements in rail engineering and stimulates the steel industry, contributing to economic growth and improved rail infrastructure.

- Q:What are the advantages of continuous welded steel rails?

- Continuous welded steel rails offer several advantages over traditional jointed rails. Firstly, they provide a smoother and more comfortable ride for trains, as there are no gaps or bumps caused by rail joints. This leads to increased safety and reduced wear and tear on both the train and the tracks. Secondly, continuous welded steel rails have higher strength and durability compared to jointed rails. They are less prone to cracking, breaking, or becoming misaligned, resulting in reduced maintenance costs and longer lifespan of the tracks. Additionally, these rails improve the efficiency and speed of trains. The absence of rail joints eliminates the need for slow-downs or speed restrictions during transitions, allowing trains to maintain higher speeds and operate more efficiently. Moreover, continuous welded steel rails contribute to noise reduction as they minimize the noise generated by the wheels passing over rail joints, resulting in a quieter environment for both passengers and nearby communities. In conclusion, continuous welded steel rails enhance safety, provide a smoother ride, increase durability, improve efficiency, and reduce noise, making them a preferred choice for modern railway systems.

- Q:What is the maximum speed that can be achieved on steel rails?

- The maximum speed that can be achieved on steel rails depends on various factors such as the design and condition of the rail, train technology, and safety regulations. However, in general, high-speed trains can reach speeds of up to 300 to 350 kilometers per hour (186 to 217 miles per hour) on steel rails.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 1993 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Exported to Thailand, India, Brazil, Egypt, Saudi Arabia, Japan, Vietnam and many other countries and regions |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao; Rizhao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Ms Light Steel Rail Q235, 55Q

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25Tons m.t.

- Supply Capability:

- 10000Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords