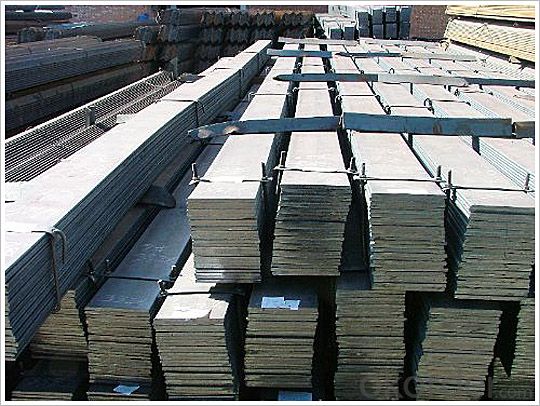

Steel Flat Bar Hot Roll 5160 Medium Carbon Round Edge Spring

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Steel Flat Bar Hot Roll 5160 Medium Carbon Round Edge Spring at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel Flat Bar Hot Roll 5160 Medium Carbon Round Edge Spring are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Flat Bar Hot Roll 5160 Medium Carbon Round Edge Spring are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Production Manufacturer | DAQIANG |

Product Name | Spring Steel Flat Bar |

Steel Type | Spring Steel |

Material | 5160 |

Others Available Material | 60Si2Mn, 5160H, SUP9, SUP9A, 55Cr3 etc. |

Thickness Range (mm) | 6-50 |

Width Range (mm) | 40-135 |

Usual length (mm) | 5800 |

Daily Capacity (Metric Ton) | 1000 |

Certificate | ISO9001: 2008 |

Edge | Round Edge / Right Angle |

Surface | None / Oil Protection |

Usage | Leaf Springs, Cultivator Blades, Garden Tools, Knifes etc. |

Samples | Free of Charge |

Chemical Composition (Common Material) | |||||||

C | Si | Mn | P | S | Cr | Cu | |

60Si2Mn | 0.56-0.64 | 1.5-2.0 | 0.7-1.0 | ≤0.035 | ≤0.035 | ≤0.35 | |

5160 | 0.56-0.64 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.04 | 0.7-0.9 | |

5160H | 0.55-0.65 | 0.15-0.35 | 0.65-1.1 | 0.6-1.0 | |||

SUP9 | 0.52-0.6 | 0.15-0.35 | 0.65-0.95 | ≤0.03 | ≤0.03 | 0.65-0.95 | ≤0.3 |

SUP9A | 0.56-0.64 | 0.15-0.35 | 0.7-1.0 | ≤0.03 | ≤0.03 | 0.7-1.0 | ≤0.3 |

55Cr3 | 0.52-0.59 | ≤0.4 | 0.7-1.0 | ≤0.025 | ≤0.025 | 0.7-1.0 | |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q:Are steel flat bars suitable for high-temperature applications?

- No, steel flat bars are generally not suitable for high-temperature applications. Steel has a relatively low melting point compared to other high-temperature materials such as stainless steel or refractory metals. When exposed to high temperatures, steel flat bars can experience dimensional changes, loss of strength, and even deformation or failure. For high-temperature applications, it is recommended to use materials specifically designed and engineered to withstand elevated temperatures, ensuring safety and performance.

- Q:How do you determine the fatigue strength of a steel flat bar?

- There are multiple steps and tests available to determine the fatigue strength of a steel flat bar. First and foremost, it is crucial to grasp the concept of fatigue strength. Fatigue strength refers to the maximum stress level that a material can endure cyclic loading without failure or damage. For a steel flat bar, determining its fatigue strength is essential to ensure its durability and reliability in applications that involve repeated or cyclic loading. One prevalent method to determine fatigue strength is through a fatigue test. This test entails subjecting the steel flat bar to cyclic loading, typically in the form of alternating tensile and compressive stresses. The test is commonly conducted using a fatigue testing machine or a universal testing machine equipped with a fatigue testing rig. During the fatigue test, the steel flat bar is loaded with a specific stress level known as the stress amplitude. The stress amplitude represents the difference between the maximum and minimum stress levels experienced by the material during each loading cycle. The test is typically carried out at a constant stress amplitude, and the number of cycles until failure is recorded. By plotting the stress amplitude against the number of cycles until failure on a graph, engineers and researchers can obtain a fatigue curve or S-N curve. This curve provides valuable information about the fatigue strength of the steel flat bar. It depicts the relationship between the stress amplitude and the number of cycles until failure, enabling the determination of the material's fatigue limit or endurance limit. The fatigue limit represents the maximum stress amplitude that the steel flat bar can withstand without experiencing failure after an infinite number of cycles. It serves as the threshold below which the material will not fail due to fatigue. Consequently, it is a critical parameter to consider in design and engineering applications. Aside from fatigue testing, other factors also impact the fatigue strength of a steel flat bar. These factors include surface finish, material composition, heat treatment, and residual stresses. If necessary, these factors can be analyzed and adjusted to enhance the material's fatigue strength. Overall, determining the fatigue strength of a steel flat bar involves conducting fatigue tests, analyzing fatigue curves, and considering various factors that influence the material's endurance limit. This information is vital to ensure the safe and reliable performance of the steel flat bar in applications subjected to cyclic loading.

- Q:Are steel flat bars suitable for fabrication of brackets or supports?

- Yes, steel flat bars are indeed suitable for the fabrication of brackets or supports. Steel flat bars are known for their strength, durability, and versatility, making them an excellent choice for various applications, including the construction of brackets and supports. The flat shape of steel bars allows for easy fabrication and manipulation, making it easier to create brackets or supports of different shapes and sizes. Additionally, steel is highly resistant to deformation, which ensures that the brackets or supports will remain sturdy and reliable over time. Moreover, steel flat bars have excellent load-bearing capabilities, making them suitable for supporting heavy loads or providing structural stability. This is particularly important in applications where brackets or supports need to withstand significant pressure or weight. Furthermore, steel flat bars can be easily welded, bolted, or otherwise attached to other structures, providing a secure and reliable connection. This allows for the fabrication of brackets or supports that can be easily integrated into existing frameworks or structures. Overall, steel flat bars are a suitable and popular choice for the fabrication of brackets or supports due to their strength, durability, versatility, and ease of fabrication. Whether it is for industrial, commercial, or residential applications, steel flat bars provide a reliable and long-lasting solution for various bracket or support needs.

- Q:Can steel flat bars be used for manufacturing storage racks?

- Yes, steel flat bars can be used for manufacturing storage racks. Steel flat bars are strong, durable, and have a high load-bearing capacity, making them suitable for supporting heavy loads in storage racks. Additionally, their flat shape allows for easy attachment of shelves and other storage components.

- Q:What are the advantages of using steel flat bars?

- There are several advantages of using steel flat bars in various applications. Firstly, steel flat bars offer exceptional strength and durability. Steel is known for its high tensile strength, making it a reliable choice for structural applications. Whether used in construction, manufacturing, or fabrication, steel flat bars can withstand heavy loads and provide long-lasting performance. Additionally, steel flat bars are highly versatile. They can be easily shaped, bent, or cut to suit specific project requirements. This adaptability makes steel flat bars suitable for various applications, including support beams, frames, braces, and brackets. Furthermore, steel flat bars have excellent corrosion resistance. When properly treated and finished, such as with galvanization or painting, steel flat bars can withstand harsh environmental conditions, including exposure to moisture, chemicals, and extreme temperatures. This corrosion resistance ensures the longevity and reliability of steel flat bars, reducing maintenance and replacement costs in the long run. Moreover, steel flat bars offer cost-effectiveness. Steel is a widely available and affordable material, making it a cost-effective option for many industries. Additionally, the durability and long lifespan of steel flat bars result in reduced maintenance and replacement expenses, providing significant cost savings over time. Lastly, steel flat bars are eco-friendly. Steel is a highly recyclable material, allowing for sustainable use and reducing the overall environmental impact. By utilizing steel flat bars in construction and manufacturing processes, companies can contribute to a more sustainable future by reducing waste and conserving natural resources. In summary, the advantages of using steel flat bars include exceptional strength, versatility, corrosion resistance, cost-effectiveness, and eco-friendliness. These characteristics make steel flat bars a preferred choice for a wide range of applications across different industries.

- Q:How is a steel flat bar different from other types of steel bars?

- A steel flat bar is different from other types of steel bars primarily due to its shape and dimensions. Unlike round or square steel bars, a flat bar has a rectangular cross-section with straight and flat edges. This unique shape makes it ideal for various applications where a flat, even surface is required. Additionally, the dimensions of a steel flat bar are generally wider and thicker compared to other types of bars. This provides enhanced strength, stability, and durability, making it suitable for heavy-duty applications. The wider surface area also allows for better load distribution and increased rigidity, making it a versatile choice for structural support. Moreover, the flat shape of the bar allows for easy and precise fabrication, welding, and machining. This makes it a popular choice for construction, manufacturing, and engineering purposes. It can be easily cut, shaped, and manipulated to fit specific requirements, making it a valuable material in various industries. Overall, the key differences between a steel flat bar and other types of steel bars lie in its shape, dimensions, and versatility. The flat profile, wider surface area, and thicker dimensions give it unique properties, making it a preferred choice for many applications.

- Q:Can steel flat bars be used in construction projects?

- Yes, steel flat bars can be used in construction projects. Steel flat bars are versatile and widely used in various construction applications due to their strength and durability. They are commonly used in the construction of buildings, bridges, highways, and other infrastructure projects. Steel flat bars are often used as structural support elements, such as in beams, columns, and braces, due to their ability to bear heavy loads and resist bending. They can also be used as reinforcement in concrete structures, such as slabs and foundations, to enhance the overall strength and stability of the construction. Additionally, steel flat bars can be easily welded, bent, and fabricated to meet specific project requirements, making them a popular choice in construction.

- Q:How do steel flat bars compare to other types of steel sections?

- Steel flat bars are different from other types of steel sections in terms of their shape and dimensions. Unlike beams or channels that have a more complex cross-section, flat bars have a simple rectangular shape with a uniform thickness. This makes them versatile and suitable for various applications such as construction, manufacturing, and fabrication. Flat bars are commonly used for structural support, as well as for creating frameworks, brackets, and supports. They are also easily weldable and can be bent or cut to meet specific project requirements. Overall, steel flat bars offer a practical and cost-effective solution for many structural and industrial applications.

- Q:Are steel flat bars suitable for making architectural elements?

- Indeed, steel flat bars are well-suited for the creation of architectural elements. Steel, being a robust and long-lasting material, can be effortlessly molded and manipulated into a variety of designs and forms. The sleek and modern appearance of steel flat bars makes them highly sought-after for architectural elements like railings, handrails, door frames, and decorative features. Architectural applications benefit greatly from the advantages offered by steel flat bars. Firstly, their high tensile strength enables them to withstand heavy loads and provide structural stability, thus making them perfect for supporting and securing architectural elements. Secondly, steel flat bars possess remarkable versatility, as they can be easily cut, bent, and welded to create intricate designs and shapes. This flexibility empowers architects and designers to fabricate unique and customized elements that perfectly match the specific requirements and aesthetic preferences of a project. Moreover, steel flat bars exhibit corrosion resistance, rendering them suitable for both indoor and outdoor applications. This durability ensures that architectural elements crafted from steel flat bars will have an extended lifespan and require minimal maintenance. Aside from their functional properties, steel flat bars also possess an aesthetic appeal. The clean lines and sleek finish of steel flat bars can elevate the overall appearance of architectural elements, infusing a modern and contemporary touch into the design of a building. All in all, steel flat bars are an appropriate choice for the creation of architectural elements, owing to their strength, versatility, durability, and aesthetic appeal. Whether utilized for structural support, decorative features, or functional elements, steel flat bars provide a reliable and visually captivating solution for a multitude of architectural projects.

- Q:What are the common methods of joining steel flat bars together?

- The common methods of joining steel flat bars together include welding, bolting, riveting, and using adhesive bonding.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Flat Bar Hot Roll 5160 Medium Carbon Round Edge Spring

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords