HD200 High quality portable bailey steel bridge components

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

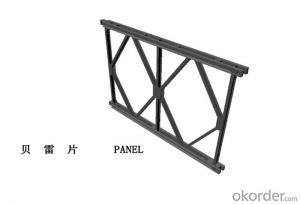

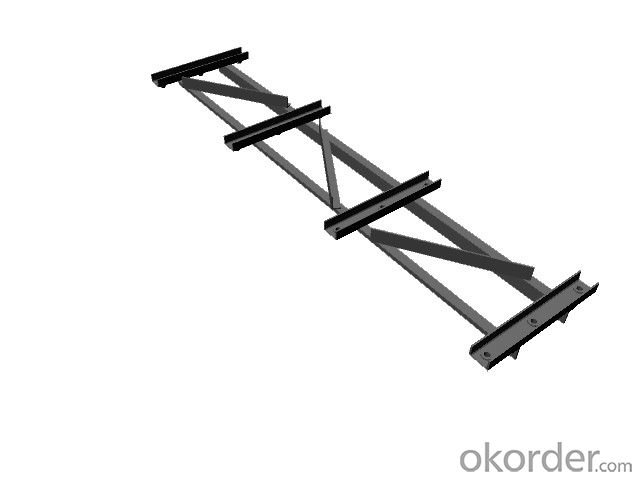

The compact 200 panel bridge is similar to the compact 100 panel bridge from their appearance. The difference is its increased panel height to 2.134m. It employed the method of alternating joints between Reinforcement Chords and the joints between panels. This method can decrease inelastic deformation caused by the oversized pinholes. Pre-arch method is used to additionally cut down mid-span and vertical deflection to a larger degree. Bolt-connected components use the orienting sleeve- fixing method to increase accuracy of connections. Shear is created in orienting sleeves and tension is developed in bolts, which increase the usage life of the bolts and ensure the safety of panel bridges. Wind resistant brace is made to be composite type and is connected to transom/girders to improve overall stability of panel bridges.

The part between braced frame and panels is fixed through bridging so as to prevent the whole bridge from side bending. After the erection, there will be a pre-arched degree over the span of the bridge. Besides it can be assembled into single-lane bridges. The compact 200 panel bridge can also be assembled into double lane bridge, hence it broadens its application range. It is suitable for the load designs of HS-15, HS-20, HS-25 and pedrail-50 etc.

- Q: How are steel structures designed for seismic zones?

- Steel structures designed for seismic zones are constructed to endure the immense forces generated during an earthquake. These structures are specifically engineered to minimize the potential damage caused by seismic activity and ensure the safety of the individuals inside. The design procedure for steel structures in seismic zones entails several crucial factors. First and foremost, the selection of suitable materials is of utmost importance. Typically, high-strength steel with excellent ductility is used as it is capable of effectively absorbing and dissipating seismic energy. The steel components are also designed to possess adequate stiffness and flexibility in order to resist lateral forces and deform under seismic loads. Another significant aspect is the structural arrangement. Buildings in seismic zones are frequently designed with lateral load-resisting systems, such as moment frames, braced frames, or shear walls. These systems provide stability and distribute seismic forces throughout the structure, thereby reducing the concentration of stress on specific elements. Furthermore, the connections between steel members are meticulously designed to ensure their ability to withstand seismic forces. Special attention is given to the detailing of connections to guarantee that they possess sufficient strength, ductility, and energy dissipation capacity. Properly designed connections can enhance the overall performance of the steel structure during an earthquake. In addition to material selection and structural arrangement, engineers also take into account the site-specific conditions and ground motion characteristics. Seismic hazard assessments are conducted to determine the expected level of ground shaking in a particular area. This information aids in establishing the design parameters and ensuring that the steel structure can safely withstand the anticipated seismic forces. Computer simulations and advanced analysis techniques, such as nonlinear dynamic analysis, are frequently employed to evaluate the behavior of steel structures under seismic loads. These tools enable engineers to assess the performance of the structure, identify potential vulnerabilities, and make necessary design modifications to enhance its seismic resistance. In summary, the design of steel structures for seismic zones is a complex process that requires a thorough comprehension of the seismic forces and their impacts. By incorporating suitable materials, structural arrangements, connection designs, and site-specific considerations, engineers can create steel structures capable of enduring seismic events and safeguarding lives and property.

- Q: What are the design considerations for steel theme parks?

- Design considerations for steel theme parks are crucial in ensuring the safety, functionality, and overall experience for park visitors. Some key considerations include: 1. Structural Integrity: Steel is a popular material choice for theme parks due to its strength and durability. Designers must ensure that the steel structures, such as roller coasters, rides, and buildings, are designed to withstand the forces they will experience during operation, including weight, wind, and vibrations. 2. Safety Measures: Safety is of utmost importance in theme parks. Designers must incorporate safety features such as guardrails, barriers, and restraints to prevent accidents and ensure the well-being of visitors. Additionally, emergency evacuation plans and systems should be integrated into the park's design to handle any unforeseen circumstances. 3. Accessibility: Theme parks should be designed with accessibility in mind to accommodate visitors with disabilities. This includes providing ramps, elevators, and accessible seating options on rides, as well as ensuring that pathways and queue lines are wide enough for wheelchair users. 4. Theme Integration: Steel theme parks often have a specific theme or storyline that is incorporated throughout the park's design. Designers must consider how to integrate steel structures in a way that complements and enhances the overall theme, creating a cohesive and immersive experience for visitors. 5. Aesthetics: Steel structures can be visually appealing and contribute to the overall ambiance of the park. Design considerations should include selecting the appropriate finishes, colors, and coatings to enhance the aesthetic appeal of the steel elements while also ensuring their longevity. 6. Maintenance and Lifespan: Steel theme parks require regular maintenance to ensure their continued operation and safety. Designers must consider accessibility for maintenance personnel, as well as the ease of replacing or repairing steel components when necessary. Additionally, considering the lifespan of steel structures is essential, as proper corrosion protection measures must be taken to prevent premature deterioration. 7. Environmental Impact: Designers should also take into account the environmental impact of steel theme parks. This includes considerations such as energy-efficient lighting, sustainable materials, and waste management practices to minimize the park's carbon footprint and promote sustainability. By carefully considering these design considerations, steel theme parks can provide a safe, enjoyable, and immersive experience for visitors while ensuring the long-term durability and success of the park.

- Q: How does steel perform in terms of vibration control?

- Steel performs well in terms of vibration control. Its high density and stiffness help to absorb and dampen vibrations, making it an effective material for applications where vibration control is important, such as in construction and machinery. Additionally, steel's ability to withstand high loads and maintain structural integrity further enhances its performance in controlling vibrations.

- Q: How are steel structures used in shopping malls and retail centers?

- Steel structures are commonly used in shopping malls and retail centers for their strength, durability, and versatility. They provide the framework for the buildings, supporting large spans and heavy loads, allowing for open and flexible floor plans. Steel also allows for quick and efficient construction, reducing costs and construction time. Additionally, steel structures can be easily modified or expanded as per the changing needs of the shopping mall or retail center, making them a popular choice in this industry.

- Q: What are the design considerations for steel water treatment plants?

- Some key design considerations for steel water treatment plants include: 1. Corrosion resistance: Steel structures must be designed with appropriate coatings or materials to resist corrosion caused by the presence of water and chemicals used in the treatment process. 2. Structural integrity: Steel structures should be designed to withstand the loads imposed by the equipment, piping, and water storage tanks within the treatment plant. 3. Expandability: The design should allow for future expansion or modifications to accommodate changing water treatment needs. 4. Accessibility and maintenance: Adequate access should be provided for inspection, maintenance, and repairs of equipment and piping systems. 5. Environmental impact: The design should incorporate measures to minimize the environmental impact of the treatment plant, such as proper waste management and energy-efficient systems. 6. Safety and security: The design should include appropriate safety features, such as fire protection systems, emergency exits, and security measures to protect the facility and its personnel. 7. Compliance with regulations: The design should adhere to applicable codes, regulations, and standards related to water treatment plants, ensuring the facility meets all legal requirements and guidelines.

- Q: How are steel structures used in the construction of food processing facilities?

- Steel structures are commonly used in the construction of food processing facilities due to their durability, strength, and ability to withstand harsh environmental conditions. These structures provide a stable framework for the facility, supporting heavy machinery and equipment, as well as ensuring the safety of workers and the integrity of the food processing operations. Additionally, steel structures can be easily customized and expanded to accommodate future growth and changes in the facility's layout, making them a cost-effective and flexible choice for food processing construction.

- Q: How are steel structures designed for efficient waste management systems?

- Steel structures are designed for efficient waste management systems by incorporating features such as proper spacing for waste storage, durable materials to withstand heavy loads, and flexible layouts to accommodate different waste disposal processes. Additionally, steel structures can be easily modified or expanded to adapt to changing waste management needs, ensuring long-term efficiency and sustainability.

- Q: What are the common challenges in the fabrication and erection of steel structures?

- To ensure successful completion of projects, it is essential to address several common challenges that arise in the fabrication and erection of steel structures. Accurate detailing and design present one of the main challenges. Precise detailing and design are crucial for proper fit and functionality of steel structures. Any errors or inaccuracies during the design phase can result in difficulties during fabrication and erection, potentially leading to structural issues or construction delays. Therefore, it is imperative to engage experienced and skilled engineers and designers who can produce accurate and detailed plans. Transportation and handling of steel components pose another challenge. Steel structures often consist of large and heavy components that need to be transported to the construction site. This requires careful planning and logistics to ensure safe and timely delivery. Additionally, proper handling equipment and techniques must be employed to prevent damage to the steel components during transportation and erection. Fabrication challenges also arise during the manufacturing process. Steel fabrication involves cutting, welding, and shaping the components according to design specifications. Skilled and experienced fabricators are essential for accurate execution of these tasks. Challenges such as material distortion, welding defects, or improper fitting can occur during fabrication, resulting in subpar quality or the need for rework. Erection challenges are common during the construction phase. Steel structures often require heavy lifting equipment and specialized techniques for assembly. Safety is a major concern during erection, as workers must operate at heights and handle heavy components. Therefore, comprehensive planning and coordination, along with adherence to safety regulations, are necessary for a smooth and safe erection process. Lastly, the coordination of different trades and subcontractors can be challenging. Steel structures often involve various subcontractors, including foundation contractors, mechanical, electrical, and plumbing contractors, and others. Coordinating these different trades and ensuring smooth communication and workflow can be a complex task. Effective project management and regular communication among all stakeholders are vital for overcoming this challenge. In conclusion, meticulous planning, skilled labor, and effective coordination are essential for the fabrication and erection of steel structures. By addressing these common challenges, projects can be completed successfully within the designated timeframe, budget, and quality requirements.

- Q: Can steel structures be easily modified or expanded?

- Yes, steel structures can be easily modified or expanded due to their inherent strength, flexibility, and modularity. Steel components can be easily added, removed, or repositioned, allowing for modifications or expansions to be made efficiently and without compromising the structural integrity of the overall building. This adaptability makes steel structures a popular choice in construction projects that may require future modifications or expansions.

- Q: How are steel structures used in the construction of recreational facilities?

- Steel structures are commonly used in the construction of recreational facilities due to their durability, versatility, and cost-effectiveness. They provide a strong and stable framework that can support various architectural designs, allowing for the creation of wide open spaces and unique shapes. Steel is also resistant to environmental factors such as corrosion and fire, making it ideal for outdoor facilities like stadiums, sports arenas, and amusement parks. Additionally, steel structures can be easily assembled and disassembled, facilitating faster construction times and minimizing disruption to ongoing recreational activities.

Send your message to us

HD200 High quality portable bailey steel bridge components

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords