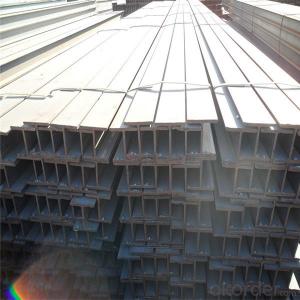

Wide Flange H Steel Beam Sizes Good Price

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 120000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick Details

OKorder is offering H BEAM at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

We can provide qualify goods,competitive price and speedy delivery.

Products Description

H Type Steel Size and Theoretical Weight | |||||

Size | Theoretical Weight | Size | Theoretical Weight | Size | Theoretical Weight |

|

|

|

|

|

|

(mm) | (kg/m) | (mm) | (kg/m) | (mm) | (kg/m) |

100*50*5*7 | 9.3 | 250*125*6*9 | 29 | 446*199*8*12 | 65.1 |

100*100*6*8 | 16.9 | 250*250*9*14 | 71.8 | 450*200*9*14 | 74.9 |

125*60*6*8 | 13.1 | 294*200*8*12 | 55.8 | 482*300*11*15 | 110.8 |

125*125*6.5*9 | 23.6 | 298*149*5.5*8 | 32 | 488*300*11*18 | 124.9 |

148*100*6*9 | 31.1 | 340*250*9*14 | 36.7 | 496*199*9*14 | 77.9 |

150*75*5*7 | 14 | 300*150*6.5*9 | 93 | 500*200*10*16 | 88.1 |

150*150*7*10 | 20.7 | 300*300*10*15 | 78.1 | 582*300*12*17 | 132.8 |

175*90*5*8 | 18 | 346*174*6*9 | 41.2 | 588*300*12*20 | 147 |

175*175*7.5*11 | 40.4 | 350*175*7*11 | 49.4 | 596*199*10*15 | 92.4 |

194*150*6*9 | 29.9 | 350*350*12*19 | 134.9 | 600*200*11*17 | 103.4 |

198*99*4.5*7 | 17.8 | 390*300*10*16 | 104.6 | 700*300*13*24 | 181.8 |

200*100*5.5*8 | 20.9 | 396*199*7*11 | 56.1 | 800*300*14*26 | 206.8 |

200*200*8*12 | 49.9 | 400*200*8*13 | 65.4 | 900*300*16*28 | 240.1 |

244*175*7*11 | 43.6 | 400*400*13*21 | 171.7 |

|

|

248*124*5*8 | 25.1 | 440*300*11*18 | 120.8 |

|

|

Length=6------12meters | |||||

Packaging & Delivery

Packaging Details: | Packed with waterproof paper and steel banding. |

Delivery Detail: | 15-25 |

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

- Q: Can steel H-beams be used in sports stadium construction?

- Yes, steel H-beams can be used in sports stadium construction. They are commonly utilized in the construction of large-scale structures like stadiums due to their strength, durability, and ability to support heavy loads. H-beams provide structural integrity and stability, making them suitable for supporting the weight of stadium roofs, seating areas, and other components.

- Q: What is the theoretical weight of welded H - section steel 900*350*20*30?

- H steel is mainly used in engineering, plant, equipment, machinery and equipment, bridges, highways, houses, etc., with good mechanical and physical properties, firm and energy-saving and environmental protection. H steel is an economical section steel, widely used in industry, construction, bridge, oil drilling and so on

- Q: Can steel H-beams be used in the construction of healthcare facilities?

- Certainly, healthcare facilities can indeed utilize steel H-beams for their construction needs. The reason behind their widespread usage in structural applications lies in their impressive strength and durability. Thanks to these qualities, steel H-beams offer exceptional support and stability, rendering them highly suitable for constructing various components of healthcare facilities, including walls, floors, and roofs. Furthermore, steel H-beams can be easily fabricated and tailored to meet specific design requirements, thereby enabling flexible and efficient construction processes. Additionally, it's worth noting that steel, being a non-combustible material, significantly enhances the fire safety of healthcare facilities. All in all, opting for steel H-beams in the construction of healthcare facilities guarantees the creation of a robust, secure, and long-lasting structure.

- Q: Can steel H-beams be used for stadium construction?

- Certainly! Stadium construction can indeed utilize steel H-beams. These H-beams are commonly employed in construction as they possess remarkable strength and versatility. Their ability to bear heavy loads and offer stability to colossal structures like stadiums makes them highly sought-after. Furthermore, steel H-beams present numerous advantages, including durability, fire resistance, and the capacity to endure extreme weather conditions. By employing these H-beams in stadium construction, it becomes possible to create vast open spaces without the necessity of intermediate columns, thereby providing unobstructed views for spectators. In summary, due to their structural integrity and suitability in supporting the specific requirements of such extensive projects, steel H-beams are an exceptional choice for stadium construction.

- Q: How are steel H-beams manufactured?

- Hot rolling is the process used to manufacture steel H-beams. It begins with the selection of high-quality steel, usually in the form of a large billet. This billet is then heated to a temperature above its recrystallization point, typically around 1200 to 1300 degrees Celsius. Once the billet reaches the desired temperature, it is fed into a rolling mill. The mill consists of a series of rollers that gradually shape the heated billet into the H-beam profile. The rollers apply pressure to the billet, causing it to elongate and take on the desired shape. This is known as hot rolling because the steel is rolled while it is still hot and malleable. Throughout the rolling process, the billet is continuously passed through the rollers, undergoing multiple passes until it achieves the required dimensions and shape. The final profile of the H-beam is determined by the shape of the rollers, with each roller gradually shaping the steel. Once the rolling process is completed, the newly formed H-beams are cooled using either air or water. This cooling process is crucial to maintaining the steel's strength and structural integrity. After cooling, the H-beams are cut to the desired lengths and undergo any necessary further processing, such as surface treatment or galvanization. Finally, they are packaged and shipped to customers. In summary, the manufacturing of steel H-beams involves heating a billet to a high temperature, rolling it through a series of rollers to shape it, cooling it, and then further processing it. This process ensures the production of high-quality and structurally sound H-beams that are used in construction and engineering projects.

- Q: Can steel H-beams be used for airport terminals?

- Indeed, airport terminals can utilize steel H-beams. Renowned for their robustness and endurance, steel H-beams find extensive employment within the construction sector. Their remarkable load-bearing capacity and ability to confer structural stability render them highly suitable for colossal edifices such as airport terminals. Furthermore, steel H-beams can be tailor-made to diverse dimensions and lengths, facilitating personalized designs that align precisely with the unique prerequisites of an airport terminal. In essence, the reliability and adaptability of steel H-beams make them an esteemed preference when erecting airport terminals.

- Q: Can steel H-beams be customized to specific lengths?

- Yes, steel H-beams can be customized to specific lengths. Steel H-beams are commonly used in construction and are available in various standard lengths. However, if the standard lengths do not meet the specific requirements of a project, they can be customized to the desired length. This can be done by cutting the beams to the required length and then welding or bolting the ends together to create the desired length. Customizing the length of steel H-beams allows for more flexibility in construction projects and ensures that the beams fit perfectly for a specific application.

- Q: Can steel H-beams be used for industrial storage facilities?

- Yes, steel H-beams are commonly used in industrial storage facilities due to their high strength, durability, and ability to support heavy loads.

- Q: Can steel H-beams be used in the construction of telecommunications infrastructure?

- Certainly! Steel H-beams are indeed suitable for the construction of telecommunications infrastructure. Their high strength-to-weight ratio makes them an excellent choice for supporting heavy loads, which is why they are commonly used in construction. In addition to this, H-beams offer exceptional structural integrity and stability, making them an ideal option for various applications such as telecommunications towers, antennas, and equipment shelters. Furthermore, steel H-beams can endure extreme weather conditions and provide the necessary support for the installation and maintenance of telecommunications equipment. Moreover, they can be easily fabricated and assembled, allowing for efficient construction and flexibility in design. All in all, steel H-beams are a dependable and long-lasting choice for the construction of telecommunications infrastructure.

- Q: What are the different grades of steel used in H-beam manufacturing?

- There are various grades of steel used in H-beam manufacturing, including ASTM A36, ASTM A572, and ASTM A992. Each grade offers different properties and strengths, allowing manufacturers to choose the most suitable grade based on the specific requirements of the H-beam application.

Send your message to us

Wide Flange H Steel Beam Sizes Good Price

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 120000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords