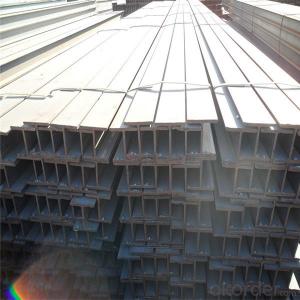

H Steel Beam from China at Good Price and Qaulity

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 100000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick Details

Place of Origin: | Tianjin, China (Mainland) | Grade: | Q235B | Technique: | High Frequency |

Application: | Building construction,Bridge construction etc. | Length: | 6.0meters,9meters,12meters | Standard: | ASTM |

Flange Width: | 100-750mm | Flange Thickness: | 3.0-10.0mm | Web Width: | 50-250mm |

Web Thickness: | 2.3-8.0mm | Brand Name: | Liye |

We can provide qualify goods,competitive price and speedy delivery.

Products Description

Description | High Frenquency Thin-walled H Beam | |

Product Name | H Beam | |

Specification | Height:75-500mm Width:50-250mm | |

Standard | GB700-1998,GB/T1591-1994 | |

Material | Q235B,Q345B | |

Application | a. Bridge and post structures in industry and civil use of steel construction. | |

Certificates | ISO,SGS,BV,TUV,Lloyd | |

MOQ | 20 tons or according to customers’ requirement. | |

Port of Delivery | Tianjin Port of China | |

Remarks | We can provide qualify goods,competitive price and speedy delivery |

Packaging & Delivery

Packaging Details: | Packed with waterproof paper and steel banding. |

Delivery Detail: | 15-25 |

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

- Q: Can steel H-beams be used in sports stadium construction?

- Yes, steel H-beams can be used in sports stadium construction. They are commonly utilized in the construction of large-scale structures like stadiums due to their strength, durability, and ability to support heavy loads. H-beams provide structural integrity and stability, making them suitable for supporting the weight of stadium roofs, seating areas, and other components.

- Q: What are steel H-beams made of?

- Steel H-beams are made primarily of carbon steel, which is an alloy of iron and carbon. The carbon content in steel gives it its strength and durability. In addition to carbon, steel H-beams may also contain small amounts of other elements such as manganese, silicon, and sulfur, which help improve its properties and enhance its performance. The manufacturing process involves heating the raw materials to high temperatures, followed by shaping the molten steel into the desired H-beam profile. The resulting product is a strong and sturdy beam that is widely used in construction, infrastructure, and various other industries.

- Q: Can steel H-beams be used for cantilever structures?

- Yes, steel H-beams can be used for cantilever structures. Cantilever structures are designed to have a projecting beam or member that is supported on only one end, with the other end free or unsupported. Steel H-beams are commonly used in construction due to their strength and load-bearing capabilities. They are well-suited for cantilever designs as they provide excellent structural support, minimizing deflection and ensuring stability. However, it is essential to consider the specific requirements of the cantilever structure and consult with a structural engineer to determine the appropriate size and strength of the H-beam needed to support the desired load and span.

- Q: How are steel H-beams transported and handled on construction sites?

- Steel H-beams are typically transported and handled on construction sites using heavy machinery and equipment. The transportation process begins with loading the H-beams onto trucks or trailers, usually using cranes or forklifts. It is important to ensure that the H-beams are properly secured during transportation to prevent any damage or accidents. Once the steel H-beams arrive at the construction site, they are unloaded from the trucks or trailers, again using cranes or forklifts. The H-beams are then moved to the designated area where they will be used in the construction process. Handling steel H-beams requires careful planning and coordination. The beams are often quite heavy and bulky, so it is crucial to have the necessary equipment and machinery to lift and maneuver them safely. Cranes are commonly used to lift the H-beams and position them into place. These cranes are often operated by trained professionals who have expertise in handling heavy loads. In some cases, steel H-beams may need to be cut or modified on site to fit specific requirements. This is typically done using specialized cutting and welding equipment. It is important to follow proper safety procedures and guidelines when performing these tasks to ensure the integrity of the H-beams and the safety of the workers. Overall, transporting and handling steel H-beams on construction sites requires careful planning, coordination, and the use of appropriate machinery and equipment. Safety should always be the top priority to prevent accidents and ensure the successful completion of the construction project.

- Q: Are steel H-beams suitable for structures with curved elements?

- No, steel H-beams are typically not suitable for structures with curved elements. They are designed to provide rigid support and stability in straight structures, and their shape does not lend well to accommodating curved elements.

- Q: What are the different methods of reinforcing steel H-beams?

- Different methods are available to reinforce steel H-beams, which are commonly used in construction to provide structural support. These methods aim to improve the strength, durability, and load-bearing capacity of H-beams, ensuring their optimal performance in various applications. 1. Welding: Welding is a widely used method to strengthen steel H-beams. By welding two or more H-beams together, a stronger and more rigid structure is created. This is achieved by melting the edges of the beams and fusing them together using heat and pressure. Welding can also be employed to attach additional steel plates or angles to the H-beam, further enhancing its overall structure. 2. Shear Connectors: Shear connectors are effective in reinforcing H-beams, especially in composite construction. These connectors, typically steel studs or bars, are welded onto the top flange of the H-beam. Their purpose is to transfer shear forces between the concrete slab and the steel beam, thereby improving the structural integrity and load-carrying capacity of the H-beam. 3. Steel Plates: Steel plates are commonly used to reinforce H-beams, particularly when dealing with heavy loads or long spans. These plates are usually bolted or welded to the web or flanges of the H-beam, providing additional strength and stiffness. The size and thickness of the steel plates can be customized based on the specific project requirements. 4. Composite Beams: Composite beams involve combining a steel H-beam with a concrete slab. This method entails placing the concrete slab on top of the H-beam and connecting them together using shear connectors like steel studs or bars. Composite beams offer numerous advantages, including increased load-carrying capacity, improved fire resistance, and enhanced overall stiffness. 5. Reinforced Concrete Encasement: Reinforcing H-beams through reinforced concrete encasement is another method. This technique involves wrapping the H-beam with reinforced concrete, which is achieved by constructing formwork around the beam and pouring concrete into it. The concrete encasement enhances the strength and stiffness of the H-beam, providing additional resistance against bending, shear, and other forces. It is important to note that the choice of reinforcing method depends on specific project requirements, such as load requirements, span length, construction constraints, and design considerations. Consulting with a structural engineer or construction professional is highly recommended to determine the most suitable method for reinforcing steel H-beams in a given application.

- Q: Can steel H-beams be used for agricultural structures?

- Yes, steel H-beams can be used for agricultural structures. Steel H-beams offer several advantages for agricultural buildings. Firstly, they are incredibly strong and durable, able to withstand heavy loads and harsh weather conditions. This makes them ideal for supporting the weight of roofs, walls, and other structural components in agricultural buildings. Additionally, steel H-beams are versatile and can be easily customized to suit the specific requirements of agricultural structures. They can be cut to different sizes and lengths, allowing for flexibility in design and construction. This flexibility also makes them suitable for various types of agricultural buildings, such as barns, storage facilities, and livestock shelters. Moreover, steel H-beams are resistant to pests, rot, and decay, which can be common issues in agricultural environments. This ensures the longevity and reliability of the structures, minimizing the need for frequent repairs or replacements. Furthermore, steel H-beams are fire-resistant, offering an added layer of safety for agricultural buildings. This can be particularly important in areas where fire hazards are a concern. Finally, steel H-beams are cost-effective in the long run. Although they may have a higher upfront cost compared to other building materials, their durability and low maintenance requirements make them a cost-efficient choice over time. Overall, steel H-beams are a suitable and practical option for agricultural structures due to their strength, versatility, durability, resistance to pests and fire, and cost-effectiveness.

- Q: How do steel H-beams perform in coastal areas with high salt content?

- If steel H-beams in coastal areas with high salt content are properly protected against corrosion, they can perform well. The corrosion process can be accelerated by the high salt content in coastal environments, but steel H-beams can still provide effective structural support if the right measures are taken. Applying protective coatings is a key factor in preventing corrosion in coastal areas. It is important to coat steel H-beams with corrosion-resistant materials like epoxy or zinc coatings. These coatings act as a barrier between the steel and the corrosive elements in the environment, preventing direct contact and reducing the risk of corrosion. Regular inspection and maintenance are crucial in coastal areas with high salt content. It is important to monitor the condition of the protective coatings and address any signs of damage or degradation promptly. This may involve touching up or reapplying the coatings to ensure continuous protection. Furthermore, proper design considerations can help mitigate the effects of salt content. For instance, engineers can incorporate drainage systems into the structure to prevent the accumulation of saltwater, which can increase the likelihood of corrosion. Adequate ventilation and airflow can also help reduce moisture levels around the steel H-beams, minimizing the risk of corrosion. It is important to note that even with these protective measures, steel H-beams in coastal areas with high salt content may still experience some degree of corrosion over time. However, with the appropriate preventive measures and regular maintenance, the performance of steel H-beams can be significantly improved, ensuring their longevity and structural integrity in these challenging environments.

- Q: Can steel H-beams be used in marine or coastal environments?

- Yes, steel H-beams can be used in marine or coastal environments. However, it is important to consider the potential challenges posed by corrosion due to saltwater exposure. Proper protective coatings or materials like stainless steel should be used to prevent corrosion and ensure the longevity of the H-beams in such environments. Regular maintenance and inspections are also crucial to identify any signs of corrosion and address them promptly.

- Q: Can steel H-beams be used for industrial storage facilities?

- Yes, steel H-beams are commonly used in industrial storage facilities due to their high strength, durability, and ability to support heavy loads.

Send your message to us

H Steel Beam from China at Good Price and Qaulity

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 100000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords