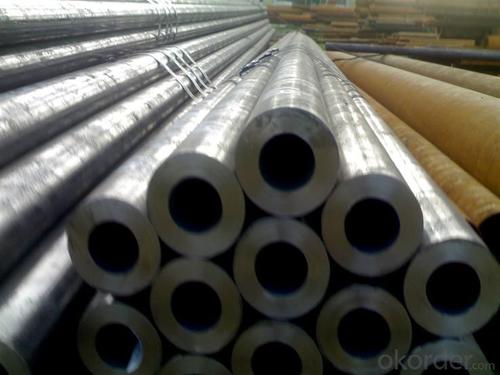

SA335/SA335M Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ASTM A335 Seamless Alloy-Steel Pipe

Standard: BS 1139, BS 3059-2, JIS G3454-2007

Grade: 10#-45#, 15NiCuMoNb5, 10Cr9Mo1VNb

Detailed introduction to ASTM A335 seamless alloy steel pipe:

ASTM A335 seamless alloy steel pipe

FAQ:

1) why you chose us ?

Professional Manufacturer and supplier of Steel pipe

More than 14 years’ professional producing experience

We can get the lowest ex-factory prices. The price are quite reasonable and it is lower than our commercial peers. also, we can guarantee the qualities of our products.

BV, ISO certificates and SGS test can be provided to assure the quality of our products.

2) Our minimum order quantity:

10 Metric Tons or one 20ft or 40ft Container.

3) How about the Delivery Time?

The steel pipe will be produced since we getting your deposit by T/T or Your original L/C. For normal size, some stocks in our factory now, we can supply once you need.

4)What kind of payment does your company support?

T/T, 100% L/C at sight, Cash, Western Union are all accepted.

5) Do you charge for the samples?

According to our company principle, we just charge for samples, you pay for the freight /courier charge.

6) Main market:

Mid East, South America, Africa, Southeast Asia, India etc

FAQ:

1) why you chose us ?

Professional Manufacturer and supplier of Steel pipe

More than 14 years’ professional producing experience

We can get the lowest ex-factory prices. The price are quite reasonable and it is lower than our commercial peers. also, we can guarantee the qualities of our products.

BV, ISO certificates and SGS test can be provided to assure the quality of our products.

2) Our minimum order quantity:

10 Metric Tons or one 20ft or 40ft Container.

3) How about the Delivery Time?

The steel pipe will be produced since we getting your deposit by T/T or Your original L/C. For normal size, some stocks in our factory now, we can supply once you need.

4)What kind of payment does your company support?

T/T, 100% L/C at sight, Cash, Western Union are all accepted.

5) Do you charge for the samples?

According to our company principle, we just charge for samples, you pay for the freight /courier charge.

6) Main market:

Mid East, South America, Africa, Southeast Asia, India etc

- Q:How do you prevent galvanic corrosion in stainless steel pipes?

- To prevent galvanic corrosion in stainless steel pipes, one can take several measures: 1. Ensure compatibility of materials: It is crucial to use compatible materials near stainless steel pipes to avoid galvanic corrosion. Avoid direct contact between stainless steel pipes and dissimilar metals like carbon steel, copper, or aluminum. 2. Insulate dissimilar metals: If it is necessary to have dissimilar metals in close proximity to stainless steel pipes, one can use electrical insulation. By electrically isolating the metals, the flow of electric current and subsequent galvanic corrosion can be minimized. 3. Apply protective coatings: Protective coatings like paint or epoxy can be applied to the external surface of stainless steel pipes. These coatings act as a barrier against galvanic corrosion by preventing direct contact between stainless steel and other metals that may cause galvanic reactions. 4. Use dielectric unions: When connecting stainless steel pipes to dissimilar metals, dielectric unions can be used to separate the metals and prevent galvanic corrosion. These unions incorporate insulating materials such as plastic or rubber to avoid direct contact between the metals. 5. Implement cathodic protection: Cathodic protection is an effective method to prevent galvanic corrosion in stainless steel pipes. By introducing a sacrificial anode like zinc or magnesium into the system, the anode corrodes instead of the stainless steel. Periodic replacement of the sacrificial anode ensures continuous protection. 6. Install corrosion-resistant alloys: If the application allows, using corrosion-resistant alloys like duplex stainless steel or titanium can provide enhanced protection against galvanic corrosion. These alloys have better resistance to galvanic reactions and are less prone to corrosion in various environments. Overall, a combination of these preventive measures can significantly reduce the risk of galvanic corrosion in stainless steel pipes, ensuring their longevity and performance. It is important to assess the specific application and environment to determine the most suitable preventive measures to be implemented.

- Q:Are stainless steel pipes suitable for industrial applications?

- Stainless steel pipes excel in industrial settings due to their exceptional corrosion resistance, rendering them a favored option across various industries such as chemical, petrochemical, oil and gas, pharmaceutical, food and beverage, and more. These pipes can endure elevated temperatures and pressures, making them perfect for transporting fluids and gases in industrial procedures. Moreover, their durability, strength, and prolonged lifespan become pivotal in heavy-duty industrial scenarios. Furthermore, stainless steel pipes necessitate effortless maintenance and cleaning, mitigating the risk of contamination in industries that mandate stringent hygiene standards. In summary, stainless steel pipes present myriad advantages that render them highly suitable and extensively employed in industrial applications.

- Q:What is the difference between duplex and super duplex stainless steel pipes?

- The main difference between duplex and super duplex stainless steel pipes lies in their chemical composition and mechanical properties. Duplex stainless steel pipes have a mixed microstructure of austenite and ferrite, offering a good balance of corrosion resistance and strength. On the other hand, super duplex stainless steel pipes have a higher content of chromium, molybdenum, and nitrogen, providing exceptional resistance to corrosion, especially in harsh environments. Super duplex stainless steel pipes also possess superior mechanical properties, such as increased tensile strength and improved resistance to stress corrosion cracking.

- Q:Are stainless steel pipes fire-resistant?

- Yes, stainless steel pipes are fire-resistant. Due to their high melting point and excellent heat resistance, stainless steel pipes can withstand extreme temperatures and prevent the spread of fire, making them a reliable choice for fire protection systems.

- Q:What is the difference between 304 and 304L stainless steel pipes?

- The carbon content is the primary distinguishing factor between 304 and 304L stainless steel pipes. 304 pipes contain a maximum of 0.08% carbon, while 304L pipes have a maximum of 0.03% carbon. The reduced carbon content in 304L pipes helps prevent carbide precipitation during welding, which can cause intergranular corrosion. 304L stainless steel pipes are more resistant to sensitization, a process where chromium carbides form at grain boundaries, leading to decreased corrosion resistance. This makes 304L pipes ideal for applications in high-temperature and corrosive environments, such as the food processing industry or chemical plants. Both 304 and 304L stainless steel pipes exhibit similar mechanical properties in terms of strength and hardness. However, the lower carbon content in 304L pipes may result in slightly higher tensile and yield strength compared to 304 pipes. Additionally, 304L pipes possess improved welding and forming characteristics, making them more manageable during fabrication. To summarize, the principal distinction between 304 and 304L stainless steel pipes lies in their carbon content. The lower carbon content in 304L pipes reduces the risk of sensitization and carbide precipitation during welding, making them better suited for applications in high-temperature and corrosive environments.

- Q:Can stainless steel pipes be used for oil and gas transportation?

- Yes, stainless steel pipes can be used for oil and gas transportation. Stainless steel is a popular material choice for pipes in the oil and gas industry due to its high corrosion resistance and durability. These pipes are able to withstand harsh conditions, such as high pressure, extreme temperatures, and corrosive environments, making them suitable for transporting oil and gas. Additionally, stainless steel pipes are known for their ability to maintain the purity of the transported fluids, as they do not react with or contaminate the substances being transported. Overall, stainless steel pipes are a reliable and efficient option for oil and gas transportation.

- Q:Can stainless steel pipes be used for swimming pool systems?

- Indeed, swimming pool systems can utilize stainless steel pipes. The reason why stainless steel is a favored option for swimming pool piping lies in its remarkable ability to resist corrosion and its durability. It is impervious to rust and can endure exposure to chlorine, saltwater, and other chemicals frequently employed in pool systems. Moreover, stainless steel pipes possess considerable strength, rendering them apt for managing the pressure and water flow within swimming pool systems. Furthermore, stainless steel pipes are simple to clean and maintain, guaranteeing a prolonged lifespan for the pool system.

- Q:Can stainless steel pipes be used in the renewable energy industry?

- Yes, stainless steel pipes can definitely be used in the renewable energy industry. Stainless steel is a highly versatile and durable material that offers numerous advantages for various applications in renewable energy systems. One of the key benefits of stainless steel pipes is their exceptional corrosion resistance. This makes them ideal for use in environments where exposure to moisture, chemicals, and other corrosive elements is common, such as in solar power plants, geothermal energy systems, and offshore wind farms. Stainless steel pipes can withstand these harsh conditions and maintain their structural integrity over long periods, reducing the need for frequent repairs and replacements. Another advantage of stainless steel pipes is their high strength-to-weight ratio, which allows for the design of lightweight and efficient renewable energy structures. Stainless steel pipes can be used in the construction of support frames, structures, and pipelines for wind turbines, solar thermal collectors, and biomass power plants, among others. Their strength and durability contribute to the overall reliability and longevity of the renewable energy systems. Furthermore, stainless steel pipes are resistant to extreme temperatures, making them suitable for use in high-temperature applications like concentrated solar power systems. These pipes can handle the intense heat generated by solar receivers without undergoing deformation or degradation, ensuring the efficient transfer of heat in the system. In addition to their mechanical properties, stainless steel pipes are also hygienic and environmentally friendly. They are easy to clean and maintain, reducing the risk of contamination and ensuring the purity of fluids in renewable energy processes. Stainless steel is also a recyclable material, aligning with the sustainability principles of the renewable energy industry. Overall, stainless steel pipes offer a reliable, long-lasting, and cost-effective solution for various applications in the renewable energy industry. Their corrosion resistance, strength, temperature resistance, and environmental benefits make them an excellent choice for transporting fluids, supporting structures, and withstanding the demanding conditions of renewable energy systems.

- Q:Can stainless steel pipes withstand high temperatures?

- Yes, stainless steel pipes can withstand high temperatures due to their excellent heat resistance properties.

- Q:How do stainless steel pipes compare to galvanized steel pipes?

- Stainless steel pipes have a higher resistance to corrosion, making them more durable and suitable for various applications. On the other hand, galvanized steel pipes are coated with zinc to prevent rust, but they are prone to corrosion over time. Additionally, stainless steel pipes are generally more expensive than galvanized steel pipes but offer superior longevity and better overall performance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SA335/SA335M Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords