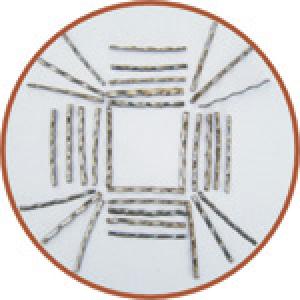

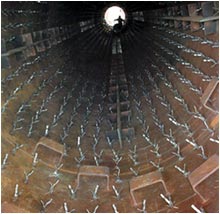

Refractory Anchor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Refractory Anchor

|

- Q: How are steel products used in the railway industry?

- Steel products are extensively used in the railway industry for various applications. Steel is commonly used for manufacturing railway tracks, train wheels, and various structural components of the railway infrastructure. Additionally, steel is used in the construction of railway cars, locomotives, and various equipment such as bridges, tunnels, and signaling systems. Its high strength, durability, and ability to withstand heavy loads make steel an ideal material for ensuring the safety and efficiency of the railway system.

- Q: How can steel products be recycled and reused?

- Steel products can be recycled and reused through a process called steel recycling. This involves collecting and sorting steel items, such as cans, appliances, and construction materials, and then processing them to remove impurities. The steel is then melted down and reshaped into new products, reducing the need for raw materials and saving energy. Additionally, steel can be reused by refurbishing or repurposing old steel items, extending their lifespan and reducing waste.

- Q: What are the uses of steel grating in walkways and platforms?

- Steel grating is commonly used in walkways and platforms due to its numerous benefits. Its primary purpose is to provide a secure and slip-resistant surface, ensuring the safety of individuals walking or standing on it. Additionally, steel grating offers excellent durability, withstanding heavy loads and extreme weather conditions. Its open design allows for efficient drainage of water, debris, and other substances, preventing the accumulation of slippery or hazardous materials. Moreover, steel grating is highly versatile, suitable for various applications such as industrial plants, commercial buildings, and public areas, making it an ideal choice for creating sturdy and functional walkways and platforms.

- Q: What is the role of steel in the manufacturing of furniture?

- Steel plays a crucial role in the manufacturing of furniture due to its strength, durability, and versatility. It is commonly used in the construction of the frame and structure of furniture pieces, providing stability and support. Steel can be formed into various shapes and sizes, allowing for creative and intricate designs. Additionally, it can be coated or finished in different ways to enhance its appearance and protect it from wear and tear. Overall, steel enhances the overall quality and longevity of furniture, making it an essential material in the manufacturing process.

- Q: How is steel billet produced?

- Steel billet is produced through a process called continuous casting, which involves melting scrap steel in an electric arc furnace and then pouring the molten steel into a water-cooled mold. As the steel cools, it solidifies into a semi-finished rectangular shape called a billet, which can be further processed into various steel products.

- Q: What are the uses of steel in the construction of airports?

- Steel is widely used in the construction of airports due to its strength, durability, and versatility. It is used for various purposes such as structural framing, roofing, cladding, and reinforcement. Steel provides the necessary strength to support the weight of the airport's infrastructure, including runways, terminals, hangars, and control towers. It also offers resistance against extreme weather conditions and can be easily fabricated and customized to meet the specific design requirements of an airport. Overall, steel plays a crucial role in ensuring the safety, longevity, and functionality of airport structures.

- Q: How is steel wire rope inspected for safety?

- Steel wire rope is inspected for safety through a comprehensive process that includes visual examination, non-destructive testing techniques, and load testing. Trained inspectors carefully examine the rope for any visible signs of wear, corrosion, or damage. Non-destructive testing methods such as magnetic particle inspection or ultrasonic testing are used to detect any internal flaws or defects that may not be visible. Additionally, load testing is conducted to determine the rope's ability to withstand its specified working load. Through these rigorous inspections, the safety of steel wire rope is ensured, reducing the risk of failure and promoting safe operations.

- Q: How do steel products contribute to the water and wastewater treatment sector?

- Steel products play a crucial role in the water and wastewater treatment sector due to their durability, strength, and corrosion resistance. They are used extensively in the construction of various infrastructure and equipment, such as pipes, tanks, pumps, and valves, which are essential for transporting, storing, and treating water and wastewater. These steel products ensure the reliability and longevity of the systems, minimizing leaks, failures, and maintenance requirements. Additionally, steel's recyclability and sustainability make it an environmentally friendly choice for the water and wastewater treatment industry.

- Q: What are the different types of steel wire mesh products?

- There are several types of steel wire mesh products, including welded wire mesh, woven wire mesh, expanded metal mesh, and perforated metal mesh. Each type has its own unique characteristics and is used for various applications such as fencing, construction, filtration, and reinforcement.

- Q: How is steel plate formed into complex shapes?

- Steel plate can be formed into complex shapes through various processes such as hot rolling, cold rolling, pressing, or bending. These methods involve applying heat or pressure to the steel plate, allowing it to be molded into the desired shape. Additionally, techniques like laser cutting or CNC machining can be used to precisely cut and shape the steel plate into intricate designs.

Send your message to us

Refractory Anchor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords