Glass Fiber Chopped Strand Mat (CSM) for Boat

- Loading Port:

- SHANGHAI

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1300 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Introduction

Chopped strand mats are made of chopped strands of 50mm in length, which are randomly dispersed and bonded together by the polyester binder in powder or emulsion.

Chopped strand mats are mainly used in FRP fields, such as hand lay-up, filament winding and molding process. The typical products are panels,tanks,boats,automotive parts, cooling towers, pipes and so on!

2.Technical data

| Model No.: | EMC100 | |

| Weight: | 100 grams per sq/m | |

| Width: | up to 3300mm | |

| Loss on Ignition: | 2-7.5 | |

| Moistrure: | ≤0.5% | |

3.Advantages

1.Excellent compatibility with resin,the surface of the product is smooth,the sealing is good,and the water and chemical resistance are strong.

2.Excellent heating resisitance.

3.Good overmolding performance,easy to cut,easy to operate,suitable for making various shapes and complex product.

4.Good resin permeability,fast soaking speed,faster curing speed and higher production efficiency.

4.Application

5.Storage:

Unless otherwise specified, fiberglass products should be stored in a dry, cool and moistureproof area. Room temperature and humidity should always be maintained at 15°C - 35°C, 35% - 65% respectively. Best used within 12 months after production date. Fiberglass products should remain in their original packaging until just prior to use.

6.Serial parameter:

| Model No. | Weight | Width | Loss on Ignition | Moistrure | Use And Craftwork | |

| (grams per sq/m) | (inch) | (mm) | (%) | (%) | ||

| AEMC | 100/150/200/220 | 41-130 | 1040-3300 | 4-10 | ≤0.2 | Specialized for Automotive |

| EMC-E | 300/450/600 | 41-130 | 1040-3300 | 2-6 | ≤0.2 | Specialized for Transformer |

| EMC-R | 200/300/450 | 41-130 | 1040-3300 | 2-5 | ≤0.2 | Hand Lay-up / FRP |

| EMC-M | 200-900 | 41-130 | 1040-3300 | 2-5 | ≤0.2 | Mode |

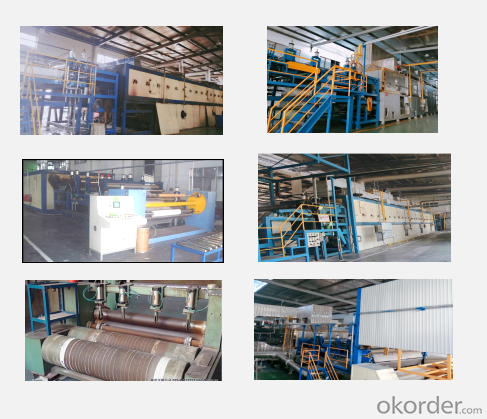

7.Our company:

Our Advantages:

1. Provide the high quality and low price product;

2. 24 hours online reply(English, Spanish and Chinese);

3. The most satisfying service Offered;

4. The safest package and transportation Offered;

5. Good after-sale service offered;

6.Your business relationship with us will be confidential to any third party.

FAQ:

Question 1: Are you a factory or a trade company?

Answer: We are a factory and have our top sales for the trade service.

Question 2: Can I try to get a SAMPLE before the order?

Answer: Sure. You can ask for the samples. Usually they're free.

Question 3: How about the lead time?

Answer: Within15-20 days after getting the prepayment.

Question 4: Where is your factory located? How can I visit there?

Answer: Our factory is located in Nanjing, Jiangsu, China. You can fly to Nanjing airport directly.

Welcome to your visit!

Question 5:Can you customize the product according to our needs?

Answer:Of course,Our company has more than ten years of experienced R & D design team, can customize products according to your needs.

- Q:Can fiberglass mat tissue be used for reinforcing concrete?

- Indeed, reinforcing concrete is possible with the utilization of fiberglass mat tissue. This lightweight and flexible material is frequently employed in construction endeavors to augment the sturdiness and endurance of concrete structures. By embedding it within the concrete, additional reinforcement is provided, which aids in averting the formation of cracks over time. Typically crafted from top-notch glass fibers that are interwoven to form a robust and steady substance, fiberglass mat tissue showcases exceptional tensile strength and corrosion resistance, rendering it an optimal selection for enhancing the performance of concrete. Whether employed in sidewalks, driveways, or other concrete formations, the presence of fiberglass mat tissue can substantially heighten the potency and lifespan of the concrete in question.

- Q:Can fiberglass mat tissue be used for HVAC ducting?

- Yes, fiberglass mat tissue can be used for HVAC ducting. Fiberglass mat tissue is a lightweight material made from glass fibers that are bonded together with a resin. It has excellent thermal insulation properties, which makes it suitable for use in HVAC systems where temperature control is important. Additionally, fiberglass mat tissue is resistant to moisture and chemicals, ensuring durability and longevity in ducting applications. It is also easy to install and can be customized to fit different duct sizes and shapes. Overall, fiberglass mat tissue is a reliable and efficient choice for HVAC ducting.

- Q:What is the chemical resistance of fiberglass mat tissue?

- Fiberglass mat tissue has excellent chemical resistance due to its composition, which includes a high percentage of glass fibers. These fibers provide a barrier against various chemicals, making the fiberglass mat tissue highly resistant to corrosion and degradation when exposed to acids, alkalis, solvents, and other harsh chemicals.

- Q:What is the dimensional stability of fiberglass mat tissue?

- The dimensional stability of fiberglass mat tissue refers to its ability to maintain its shape and size even when exposed to changes in temperature, humidity, or mechanical stress. Due to its high strength and stiffness, fiberglass mat tissue is known for its excellent dimensional stability, making it suitable for various applications such as insulation, reinforcement, and composite materials.

- Q:Is fiberglass mat tissue suitable for insulation in HVAC ducts?

- Yes, fiberglass mat tissue is suitable for insulation in HVAC ducts. It is a common and effective choice for providing thermal insulation, as it helps to reduce heat loss or gain in the ductwork. Additionally, fiberglass mat tissue is also resistant to mold and moisture, making it a reliable option for HVAC systems.

- Q:How does the fiber orientation of fiberglass mat tissue affect its strength?

- The fiber orientation of fiberglass mat tissue greatly affects its strength. When the fibers are aligned in a specific direction, they provide maximum strength in that direction. However, if the fibers are randomly oriented, the overall strength of the material is reduced as the load may not be evenly distributed among the fibers. Therefore, proper fiber orientation is crucial in maximizing the strength of fiberglass mat tissue.

- Q:Is fiberglass mat tissue suitable for wind energy applications?

- Yes, fiberglass mat tissue is suitable for wind energy applications. It is commonly used as a reinforcement material in wind turbine blades due to its high strength-to-weight ratio, excellent fatigue resistance, and ability to withstand harsh environmental conditions. The fiberglass mat tissue enhances the structural integrity and durability of the blades, enabling them to efficiently capture wind energy and sustain long-term operation.

- Q:How thick is fiberglass mat tissue typically?

- Fiberglass mat tissue typically has a thickness ranging from 0.3 to 0.6 millimeters.

- Q:What is the thermal stability of fiberglass mat tissue?

- The ability of fiberglass mat tissue to endure high temperatures without significant degradation or loss of physical properties is referred to as its thermal stability. Fiberglass mat tissue is typically crafted from woven or non-woven glass fibers, renowned for their exceptional resistance to heat. Depending on the specific type and composition, fiberglass mat tissue can generally withstand temperatures ranging from approximately 100°C (212°F) to 500°C (932°F). At these temperatures, the glass fibers retain their strength, dimensional stability, and insulation properties. The thermal stability of fiberglass mat tissue holds great importance in diverse applications where exposure to high temperatures is anticipated. For instance, it is commonly employed in the construction industry for insulation purposes in buildings. This is because it has the capability to endure the heat generated by HVAC systems or fire. Furthermore, the thermal stability of fiberglass mat tissue is also vital in industries such as automotive, aerospace, and marine. In these industries, it is utilized for heat shielding, fire protection, and insulation in engine compartments, exhaust systems, and other environments with elevated temperatures. In conclusion, the thermal stability of fiberglass mat tissue establishes it as a dependable and long-lasting material choice for applications necessitating resistance to high temperatures. Its capacity to preserve its properties under extreme heat conditions guarantees enduring performance and safety across various industries.

- Q:Can fiberglass mat tissue be used for repairing fiberglass fenders?

- Yes, fiberglass mat tissue can be used for repairing fiberglass fenders. It is commonly used in fiberglass repair work to reinforce and strengthen damaged areas.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Glass Fiber Chopped Strand Mat (CSM) for Boat

- Loading Port:

- SHANGHAI

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1300 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords