Carbon fiber composite core conductor

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 meters m

- Supply Capability:

- 200000km m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon fiber composite core conductors(hereafter called CFCC for short) consists of composite core and annealed aluminum formed wires outer layer. The annealed aluminum formed wires out layer and its adjacent layer are trapezoidal cross-section. CFCC is a kind of carbon fiber products with high performance. Compared with the traditional aluminum conductors steels-reinforced(hereafter called ACSR for short), it has series of advantages including light weight, high tensile strength, high heat resistance, corrosion resistance, high current carrying capacity etc.

In the case of the same weight, CFCC has higher current carrying capacity, which will be twice of the conventional ACSR. The tensile strength of the ACSR is 1240MPa, and high strength steel conductors is 1410MPa, however CFCC can b up to 2400MPa which increase the safety.

CFCC has good anti-aging performance and long operating life. It avoids the trouble that the ACSR’ electrochemical corrosion between the aluminum and galvanized steel core, compared with the ACSR, CFCC resist acid rain corrosion.

CFCC has good resistance to wind load. With its high strength, light weight, cross section covered by aluminum formed wire, small diameter.

CFCC has the ability of melting snow and ice. The outer layer has no gaps and is compacted smoothly. Snow and ice is not easy to be freezed. The conductor will melt snow and ice by itself when it is running under high temperature also.

CFCC has high current carrying capacity to reducing electricity generation cost and saving energy. It will reduce the ling loss by 28% in the case of same transmission capacity.

CFCC represent the technical development tide of overhead conductors. It has obvious economic and social benefits. It conduce to building safe, environmentally-friendly, efficient electricity grid.

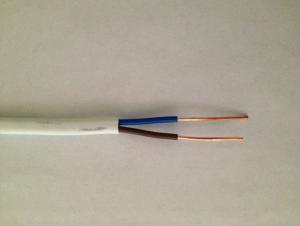

- Q: Install the socket wire is black and green to how to correspond. Rush!

- This is not an accurate answer, because the thickness of the blinds used in different aluminum, corners of different ways, very different.

- Q: Hydropower transformation with a few square of the wire is good? Recommend a good brand?

- The middle of the partition with the inside there may be weak electrical cable, and strong electric cable separate.

- Q: I will be installing spray in foam in the wall cavities and am wondering if I should have all of the wiring replaced (electrical outlets and the such) before. I've read it's difficult to replace wiring once the foam has become rigid. My fear is that a wire will short and the electrical outlet will become useless (due to previously stated problem). Any information is greatly appreciated.

- this is one of those scratch your head questions. on one hand if your electrical works fine now, in theory it should continue to work fine, but if you ever did have a problem it would be a nightmare to replace wiring in those spray foam walls but not impossible. i would say if you have gutted the walls to the bare studs and have the money to replace the wiring in those walls that are going to be insulated it wouldn't be a bad thing. far as that goes you could run a piece of pvc conduit for the outlets or switches stub just above the wall, then if you ever had a problem in the future it would be no problem to pull the wire out and replace it. if they are spraying the insulation in the wall with sheet rock in place then that's going to get kinda expensive replacing the wiring in the walls, will be very labor intensive fishing wires down the walls. i guess you have to decide to either roll the dice or not.

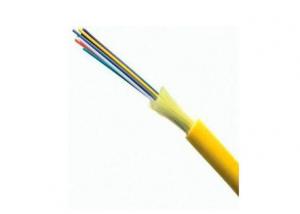

- Q: I am wiring a new screened-in porch, and i need to run wires to a switch box through conduit. I plan to run conduit from the basement out to the box and then into the ceiling, where i will then change the wire into reqular Romex when it is in the enclosed ceiling. I need to know how many wires will fit in the conduit. I was planning on using 1 inch conduit from and to the switch box. I am using 14-2 wire through a 1 conduit. thanks

- you can fit 14/2 into 3/8 conduit although not recommended. What I suggest for a pro looking job (assuming you're bending) is get 1/2 conduit and run a string/cable for pulling, and either pull the wires, or pre pull or route your pull string before you bend. If you're going with the easier don't pre pull, just fit up and cut first, then run everything you can before you connect the conduit (unless you're going steam proof) In my mind, the best way to do conduit wiring (which is great) is to have the fewest joins possible (remember, i'm industrial) so you have the fewest breaks, the fewest chances of corrosion, and the least chances of pinching in threaded joints. The trick is when bending by the way, is normal conduit has a 32% spring back, so take it a little further than you want to bend it, and low and behold, it will be darn close to exactly what you want that and bending tubing, expecially conduit, is not an exact science.

- Q: Can I spice into a near by electrical outlet to run electricty to my new range vent? Is it difficult? Seems like it would not be, but I am looking for picutures or easy steps and list of materials I will need.

- Yes. You can tie into a nearby receptacle. IF it is not a kitchen receptacle.

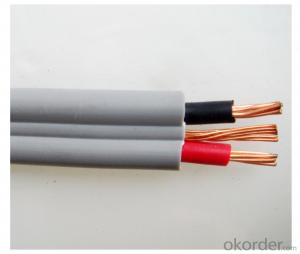

- Q: Home appliances used in the wire. To the market to buy copper wire and a copper wire and copper wire which two of them a good point? How to identify the authenticity? More

- The cable tray will heat up, and it will do so because the disk will lead to heat accumulation, which will affect the heat dissipation and will burn the wire in a serious way. Especially when the maximum current carrying capacity of the wire is more obvious, the wire tray is used up Can not exceed the rated capacity of more than 1/2 "inside the two lines of the current direction at any time can be offset each other to produce the electromagnetic effect" This is very right, the use of wire tray will not increase the wire impedance, But can not be a single wire, must be the same circuit with two at the same time disk up

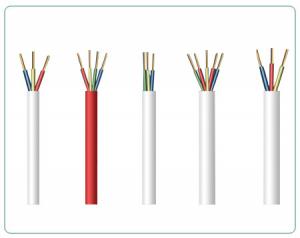

- Q: How many square wires are used for home wires? It is best to have a detailed answer

- ZR: flame retardant K: control cable code VV: recording ethylene insulation and sheath R: soft structure conductor (multi-strand wire) P: copper wire braid shield 1: 1 to 2 * 1.5: two 1.5 square single Twisted pair Full name is: flame retardant type recording ethylene insulated and sheathed copper wire braided shielded flexible cable. If it is 10 pairs of 2 by 1.5 square control cable, that is 10 * 2 * 1.5. In addition, the control cable, the conductor is the largest square: 4 square.

- Q: I come across electrical wire connectors often and they are varied.I find it difficult and sometime impossible to remove a wire from a connector without damaging the wire or the connector. Is there anyone who know how to handle these?

- cut off power first. if they are pluged in the back instead of screwed to the side then its hard not to break them. realy nuthing good that will help. try a pair of pliers and twist and pull.

- Q: I see military shoes, painted and then thrown on a telephone or electrical wire when people leave the Army, just wondering if other posts or military instalations around the US see this. I won't say were I am at, I don't want a MySpace thing happening to me, lets just say I am in the south. Does this happen anywhere elseanyone?

- Happens at every post I've ever been to. Glad to know some things even as silly as that still seem to be traditional

- Q: I never had this happen before. I had pre cooked bacon in the microwave, on a paper towel and cooked it for 135 sec. This is what I do all the time and never smelled like wires burning. It usually smelled good.

- maybe wires burning get it checked micro draw a lot of current if it is an older house the wiring may not be up to the load have someone check it for you

Send your message to us

Carbon fiber composite core conductor

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 meters m

- Supply Capability:

- 200000km m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords