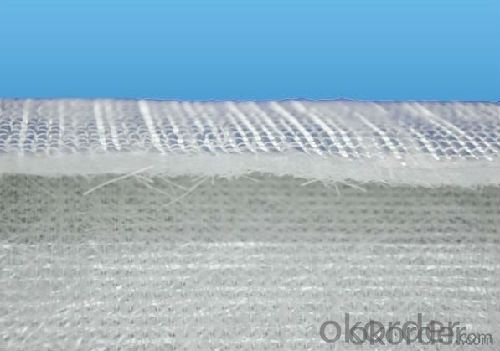

FIBERGLASS WOVEN ROVING COMNO MAT, DENSITY 900g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description & application | |||||||||||||||||||||||||||||||||||||||

Fiberglass Stitch Combo Mat is a mat made by stitching together with woven roving and a layer of evenly distributed chopped strands.

It consists of two or more layers of fiber glass rovings which are stitch-bonded. one layer of rovings and differene layers of rovings can be oriented differently and have different linear density. the roving specification, number of roving layers, mat width and roll diameter can be customized as per requirement.

This product is widely used in hand lay-up and RTM processes. It is mostly widely used in boat industry, typical end-use application include FRP boat hulls, automotive shell and door, laminates, cooling apparatus and structural shapes. | |||||||||||||||||||||||||||||||||||||||

Product Traits: | |||||||||||||||||||||||||||||||||||||||

◎ Increase strength, reduce product weight and better surface finish. | |||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers.

FAQ

1. How can you guarantee the quality? We only provide the materials that have been approved by many customers and little claim or no claim on it. We have signed the obligation contract with the manufacturer. If the few quality issue happened, we can work with the manufacturer to solve it and customer’s benefit can be guaranteed.

2. Which delivery term will you usually offer? We usually offer FOB Chongqing, FOB Shenzhen, FOB Shanghai or CIF port (defined by the customer).

| |||||||||||||||||||||||||||||||||||||||

- Q:What is the fire rating of fiberglass mat tissue?

- The fire rating of fiberglass mat tissue differs based on its specific composition and the standards it has been tested against. Typically, fiberglass mat tissue is engineered to possess fire-resistant qualities, but the actual fire rating relies on variables like the tissue's thickness and any supplementary fire retardant coatings or treatments. To ascertain the fire rating of a particular fiberglass mat tissue product, it is advisable to refer to the manufacturer's specifications or test reports, as they offer the most precise and current information available.

- Q:Can fiberglass mat tissue be used in marine applications?

- Yes, fiberglass mat tissue can be used in marine applications. It is commonly used in boat building and repair due to its excellent strength, corrosion resistance, and durability in marine environments.

- Q:What is the lifespan of fiberglass mat tissue?

- The lifespan of fiberglass mat tissue can vary depending on factors such as the quality of the material, environmental conditions, and proper maintenance. However, on average, fiberglass mat tissue can last anywhere from 20 to 30 years.

- Q:How is fiberglass mat tissue used in the production of sports equipment?

- Fiberglass mat tissue is used in the production of sports equipment as it provides strength, flexibility, and durability to the final product. It is commonly used as a reinforcement material in the manufacturing of sports equipment such as snowboards, surfboards, hockey sticks, and tennis rackets. The fiberglass mat tissue is typically layered with resin and other materials, forming a composite structure that enhances the overall performance and longevity of the sports equipment.

- Q:Can fiberglass mat tissue be used for insulation in underground pipelines?

- Indeed, insulation in underground pipelines can be achieved using fiberglass mat tissue. Renowned for its outstanding thermal insulation characteristics, fiberglass mat tissue is widely employed across diverse industrial sectors, including underground pipeline installations. By impeding heat transfer between the pipeline and its surroundings, it effectively sustains the desired temperature within the pipeline, thereby providing insulation. Furthermore, fiberglass mat tissue exhibits resistance against moisture, chemicals, and corrosion, rendering it an optimal selection for underground scenarios where pipelines face harsh conditions. Consequently, fiberglass mat tissue emerges as a dependable and efficacious insulation material for underground pipelines.

- Q:How does the density of fiberglass mat tissue affect its performance?

- The performance of fiberglass mat tissue is significantly impacted by its density. Fiberglass mat tissue finds its use in various applications such as insulation, construction materials, and composite materials. The strength, durability, flexibility, and thermal insulation properties of the fiberglass mat tissue are determined by its density. A higher density fiberglass mat tissue generally offers improved strength and durability. This is because a higher density means that more fiberglass strands are densely packed together, resulting in a denser and stronger material. It can withstand higher loads and impacts, making it suitable for applications that require structural integrity, like the construction or automotive industries. Furthermore, the flexibility of fiberglass mat tissue is also influenced by its density. A lower density fiberglass mat tissue tends to be more pliable and easier to shape. It can be molded into intricate shapes and contours, making it suitable for applications where flexibility is crucial, such as boat manufacturing or automotive body parts. The density of fiberglass mat tissue also affects its thermal insulation properties. Higher density fiberglass mat tissue provides better insulation against heat transfer. It effectively prevents the transfer of heat through conduction, making it ideal for insulation purposes in buildings or piping systems. However, it is important to consider that the choice of fiberglass mat tissue density should be based on the specific requirements of the application. While higher density may offer better strength and durability, it also increases the weight and cost of the material. Therefore, a balance needs to be achieved between the desired performance characteristics and the practicality of the specific application.

- Q:How does the width of fiberglass mat tissue affect its conformability?

- The width of fiberglass mat tissue can have a significant impact on its conformability. Generally, a wider width of fiberglass mat tissue allows for greater flexibility and adaptability to different surfaces and shapes. This is because a wider mat tissue can cover larger areas, allowing for smoother transitions and better conformability to irregular surfaces. On the other hand, a narrower width of fiberglass mat tissue may be more rigid and less able to conform to complex shapes or contours. It might struggle to properly adhere to uneven surfaces, resulting in potential gaps or imperfections. Additionally, a narrower width may limit the flexibility and maneuverability of the mat tissue during installation or application. Therefore, the width of fiberglass mat tissue is an important factor to consider when determining its conformability. A wider width generally offers better conformability and the ability to cover larger areas, while a narrower width may have limitations in adapting to complex surfaces.

- Q:Is fiberglass mat tissue suitable for electrical insulation applications?

- Yes, fiberglass mat tissue is suitable for electrical insulation applications. It possesses excellent dielectric properties, high tensile strength, and thermal resistance, making it an ideal material for insulating electrical components and preventing electrical current leakage.

- Q:How is fiberglass mat tissue manufactured?

- Fiberglass mat tissue is manufactured through a multi-step process that involves the use of glass fibers and a binder material. The first step in the manufacturing process is the production of glass fibers. This is typically done by melting raw materials such as silica sand, limestone, and soda ash in a furnace. The molten glass is then forced through tiny holes in a spinneret, which creates fine strands of glass fibers. Once the glass fibers are produced, they are pulled together to form a continuous mat. This is achieved by passing the fibers through a series of rollers or air jets that align and compress the fibers into a uniform sheet. At this stage, the mat is still loose and fragile. To give the fiberglass mat tissue its strength and stability, a binder material is added. This binder can be a resin or a combination of resins and additives. The binder is typically sprayed onto the mat, allowing it to penetrate and bond with the glass fibers. This process is known as wet-laid manufacturing. After the binder is applied, the fiberglass mat tissue goes through a curing process. This can involve the use of heat, pressure, or both, depending on the specific requirements of the product. The curing process helps to harden the binder and ensure that it securely holds the glass fibers together, creating a strong and durable mat. Once the curing process is complete, the fiberglass mat tissue is dried to remove any excess moisture. It is then trimmed and cut into the desired dimensions. Depending on the intended application, the mat may undergo additional treatments such as surface coatings or laminations to enhance its performance properties. Overall, the manufacturing process of fiberglass mat tissue involves the production of glass fibers, the formation of a continuous mat, the addition of a binder material, curing, drying, and final processing. This process ensures that the resulting fiberglass mat tissue is strong, flexible, and suitable for a wide range of applications such as insulation, reinforcement in composites, or roofing materials.

- Q:What is the moisture vapor transmission rate of fiberglass mat tissue?

- The moisture vapor transmission rate of fiberglass mat tissue can vary depending on various factors such as the specific composition of the material and its thickness. However, in general, fiberglass mat tissue has a relatively low moisture vapor transmission rate. This means that it has a relatively low ability to allow moisture vapor to pass through it. This characteristic makes it a suitable material for applications where moisture resistance is desired, such as in insulation or construction materials. However, it is important to note that the moisture vapor transmission rate of fiberglass mat tissue can be further influenced by other factors such as the presence of coatings or laminations, which may enhance or restrict its moisture vapor transmission properties.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FIBERGLASS WOVEN ROVING COMNO MAT, DENSITY 900g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords