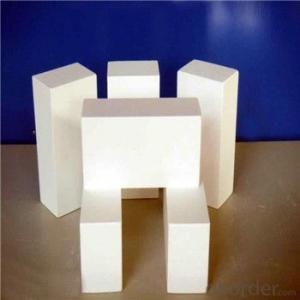

High Temperature Refractory High Density Fire Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

Refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Can insulating fire bricks be cut or shaped as needed?

- It is possible to cut or shape insulating fire bricks according to one's needs. These bricks are manufactured using lightweight materials like ceramic fibers and refractory materials, which make them more easily cut and shaped compared to traditional dense fire bricks. Cutting them can be done effortlessly using a saw or a specialized cutting tool, while shaping can be achieved through grinding, sanding, or chiseling. The ability to cut and shape them gives the advantage of custom fitting the insulating fire bricks to specific applications or structures. However, it is crucial to emphasize that precautions must be taken for safety while cutting or shaping the bricks. Wearing protective goggles, gloves, and a dust mask is essential in order to prevent inhaling any hazardous particles.

- Q: Can insulating fire bricks be used in the construction of pottery extruders?

- Yes, insulating fire bricks can be used in the construction of pottery extruders. These bricks are known for their high heat resistance, low thermal conductivity, and excellent insulating properties, making them suitable for applications where high temperatures are involved, such as pottery extrusion. They can help maintain a consistent temperature within the extruder, ensuring optimal working conditions for the clay and improving overall efficiency.

- Q: How do insulating fire bricks affect the overall moisture control of a structure?

- Insulating fire bricks play a crucial role in moisture control in a structure. These bricks are made from materials with low thermal conductivity, such as ceramic fibers or refractory materials, which enable them to efficiently insulate against heat transfer. This insulation property not only helps in reducing heat loss or gain, but it also has a significant impact on moisture control. Due to their low thermal conductivity, insulating fire bricks act as a barrier to prevent the transfer of heat and moisture between the interior and exterior of a structure. This barrier helps maintain a stable and controlled environment within the building, minimizing the chances of condensation and moisture build-up. In regions with high humidity levels or in buildings where moisture infiltration is a concern, insulating fire bricks can help prevent the accumulation of moisture on the interior surfaces. Moisture infiltration can lead to various issues such as mold growth, corrosion, and deterioration of building materials. However, by effectively insulating the structure, these bricks reduce the risk of condensation forming on the surfaces, thus minimizing the potential for moisture-related problems. Furthermore, insulating fire bricks also have a high resistance to water absorption. This characteristic makes them less susceptible to moisture damage and ensures that they do not contribute to moisture problems within the structure. Their resistance to water absorption also helps in maintaining the integrity and longevity of the bricks themselves, as excessive moisture can lead to cracking, spalling, or degradation of the material. In summary, insulating fire bricks positively impact the overall moisture control of a structure by providing effective insulation against heat transfer and minimizing the potential for condensation and moisture accumulation. By acting as a barrier and resisting water absorption, these bricks contribute to a stable and controlled indoor environment while protecting the building materials from moisture-related damage.

- Q: Are insulating fire bricks resistant to chemicals?

- Insulating fire bricks, in general, exhibit resistance to chemicals. They are specifically engineered to endure extreme temperatures and possess minimal thermal conductivity, making them a prime selection for chemical-related applications. These bricks are typically composed of ceramic materials, such as alumina, renowned for their exceptional chemical resistance properties. Nonetheless, it is crucial to recognize that the extent of chemical resistance can fluctuate based on the specific variant of insulating fire brick and the chemicals involved. Certain chemicals, particularly those highly corrosive or reactive in nature, may still inflict harm or deterioration on the bricks over time. Thus, seeking detailed information on the chemical resistance capabilities of specific insulating fire bricks from the manufacturer or supplier is highly recommended.

- Q: Can insulating fire bricks be cut or shaped to fit specific applications?

- Yes, insulating fire bricks can be cut or shaped to fit specific applications. Insulating fire bricks are made from lightweight refractory materials, typically ceramic fibers or lightweight aggregates, which allows them to be easily cut or shaped without compromising their structural integrity. They can be cut with a saw, knife, or other cutting tools to fit specific dimensions or shapes required for various applications, such as lining kilns, furnaces, or fireplaces. Additionally, insulating fire bricks can be shaped by using molds or by hand molding during the manufacturing process. This flexibility in cutting and shaping makes insulating fire bricks highly versatile and suitable for a wide range of industrial and residential applications.

- Q: Can insulating fire bricks be used in the construction of pottery kiln shelves?

- Yes, insulating fire bricks can be used in the construction of pottery kiln shelves. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation, making them an ideal material for kiln shelves. They can help maintain consistent heat distribution and prevent thermal shock, which is important for firing pottery. Additionally, insulating fire bricks are lightweight and easy to handle, making them a practical choice for constructing kiln shelves.

- Q: Can insulating fire bricks be used in the construction of industrial boilers?

- Yes, insulating fire bricks can be used in the construction of industrial boilers. Insulating fire bricks are specially designed to have low thermal conductivity, which means they are excellent at retaining heat and are ideal for applications where high temperatures need to be maintained. In the case of industrial boilers, insulating fire bricks can be used as lining material in the combustion chamber and other areas of the boiler where insulation is required. The use of insulating fire bricks in industrial boilers offers several advantages. Firstly, their low thermal conductivity helps to reduce heat loss, improving the overall energy efficiency of the boiler. This can result in significant cost savings over time. Additionally, insulating fire bricks have a high resistance to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking. This is important in boiler applications where the temperature can fluctuate frequently. Furthermore, insulating fire bricks are lightweight and relatively easy to install, making them a convenient choice for construction projects. They can be easily shaped and cut to fit the specific requirements of the boiler, allowing for a precise and efficient installation process. Overall, the use of insulating fire bricks in the construction of industrial boilers is a suitable choice due to their excellent thermal insulation properties, resistance to thermal shock, and ease of installation.

- Q: What is the typical creep resistance of an insulating fire brick?

- The creep resistance of insulating fire bricks can differ depending on their specific composition and manufacturing process. However, overall, these bricks possess excellent creep resistance properties due to their high temperature stability and low thermal conductivity. They are specifically designed to endure high temperatures and are commonly used in applications where thermal insulation and resistance to thermal stress are crucial, such as in kilns, furnaces, and other industrial processes involving high temperatures. Insulating fire bricks typically consist of lightweight refractory materials like alumina, silica, or other refractory oxides. These materials are chosen for their ability to withstand deformation and maintain their shape even at high temperatures. Creep refers to the gradual deformation or flow of a material under constant stress over time. In the case of insulating fire bricks, creep resistance pertains to their capacity to retain their structural integrity and dimensional stability when exposed to prolonged high temperatures. Insulating fire bricks are engineered to have low creep rates, meaning they exhibit minimal deformation or flow under sustained stress. This is achieved through the careful selection of raw materials, controlled manufacturing processes, and the incorporation of specific additives or binders that enhance the brick's creep resistance. While the exact values of creep resistance may vary, insulating fire bricks are generally designed to endure high temperatures and exhibit strong resistance to creep, ensuring long-lasting performance and durability in high-temperature environments.

- Q: Can insulating fire bricks be used in a refractory lining?

- Yes, insulating fire bricks can be used in a refractory lining. Insulating fire bricks are made from lightweight materials and have high insulating properties, which make them suitable for use in refractory linings to reduce heat loss and improve energy efficiency.

- Q: Are insulating fire bricks resistant to moisture absorption?

- Yes, insulating fire bricks are highly resistant to moisture absorption. They are designed to have low porosity and are made from materials that do not readily absorb water. This makes them ideal for applications where moisture resistance is crucial, such as in kilns, furnaces, and other high-temperature environments.

Send your message to us

High Temperature Refractory High Density Fire Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords