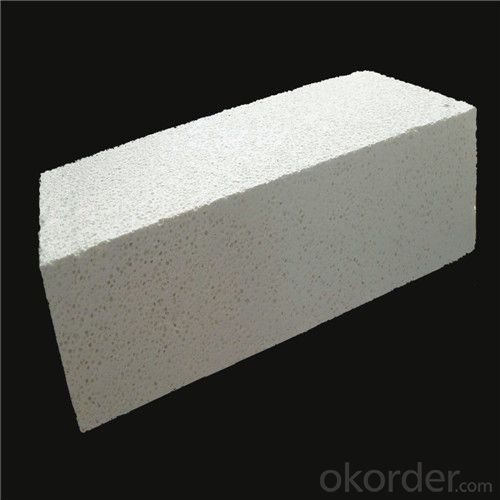

High-Temperature Insulating Fire Brick for Fire Resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

nsulating Firebrick is made of high grade bauxite through high temperature calcinations. High alumina brick is a kind of neutral refractory material so that it enjoys excellent resistance

to acid and alkali corrosion. It has characteristic of high refractoriness under load, which decide high alumina brick is a n ideal material for various kinds of industrial furnace. It is widely

used in building lining of hot-blast stove, blast furnace, coke oven, rotary kilns of cement and so on.

characteristics: 1 Excellent thermal stability

2 High refractoriness under load

3 Chemical stability and anti-corrision

4 Small high temperature creep rate

5 Excellent thermal shock resistance

Typical Application: 1 Building materials for blast furnace

2 Building materials for hot-blast stove

3 Building materials for coke oven

4 Building materials for steel making furnace

5 Kiln car building

6 For ladle

Product Type: fireclay brick (SK 32, SK 34)

high alumina brick (sk 35-38)

Package: pallet, thermal shrinkage package

Technical Data

Item | Fireclay Brick | High Alumina Brick | |||||

SK32 | SK34 | SK35 | SK36 | SK37 | SK38 | ||

Al2O3 (%) ≥ | 38 | 42 | 48 | 55 | 65 | 75 | |

Refractoriness (oC) ≥ | 1670 | 1730 | 1750 | 1770 | 1790 | 1810 | |

Refractoriness under Load (oC) ≥ | 1250 | 1300 | 1420 | 1470 | 1500 | 1520 | |

Linear Change (%) (2h) | 1350 oC | 1350 oC | 1450 oC | 1500 oC | 1500 oC | 1500 oC | |

-0.5 | -0.5 | -0.4-+0.1 | -0.4-+0.1 | -0.4-+0.1 | -0.4-+0.1 | ||

Porosity (%) ≤ | 26 | 26 | 22 | 22 | 23 | 23 | |

Cold Crushing Strength, MPa ≥ | 15 | 20 | 39.2 | 44.1 | 49 | 53.9 | |

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: Can insulating fire bricks be installed in both industrial and residential settings?

- Insulating fire bricks can be utilized in both industrial and residential environments. These bricks are specifically engineered to endure extreme temperatures and offer superb insulation, rendering them appropriate for various purposes. In industrial settings, insulating fire bricks are frequently employed in furnaces, kilns, and ovens, as they aid in conserving energy and ensuring stable temperatures. In residential settings, they can be employed in fireplaces, wood-burning stoves, and pizza ovens, enhancing heat retention and promoting safety. Due to their versatility and durability, insulating fire bricks are a dependable option for installations in both industrial and residential settings.

- Q: Do insulating fire bricks expand and contract with temperature changes?

- Yes, insulating fire bricks do expand and contract with temperature changes. Like any material, when exposed to heat, the insulating fire bricks expand, and when cooled, they contract. This expansion and contraction occur due to the thermal expansion coefficient of the material, which determines how much it will expand or contract for a given change in temperature. It is important to consider this property when using insulating fire bricks in applications where temperature fluctuations are expected, as failure to account for the expansion and contraction may lead to structural damage or cracking.

- Q: Are insulating fire bricks resistant to ultraviolet (UV) radiation?

- Insulating fire bricks usually lack resistance to ultraviolet (UV) radiation, which can lead to the deterioration and discoloration of materials, particularly those not specifically engineered to endure it. The main purpose of insulating fire bricks is their high temperature resistance and insulation properties, rather than their capacity to withstand UV radiation. Consequently, if exposed to long-term UV exposure, insulating fire bricks may undergo reduced performance, cracking, or deterioration. To ascertain the precise UV resistance of insulating fire bricks, it is crucial to refer to the manufacturer's specifications or guidelines, as certain manufacturers may provide specialized products with greater UV resistance.

- Q: Are insulating fire bricks resistant to cracking under pressure?

- Yes, insulating fire bricks are designed to be highly resistant to cracking under pressure. They are specifically manufactured to withstand high temperatures and thermal shocks while maintaining their structural integrity.

- Q: What is the typical bulk density of an insulating fire brick?

- The average bulk density of an insulating fire brick generally ranges from 0.6 to 1.2 grams per cubic centimeter (g/cm³). Nevertheless, it should be emphasized that the actual bulk density can differ based on the specific composition and manufacturing procedure of the insulating fire brick.

- Q: Can insulating fire bricks be used in low-temperature applications as well?

- Yes, insulating fire bricks can be used in low-temperature applications. These bricks are designed to have low thermal conductivity, making them suitable for retaining heat and insulating against temperature fluctuations. They can effectively withstand lower temperatures while still providing insulation and preventing heat loss.

- Q: Can insulating fire bricks be used in contact with molten metals?

- Yes, insulating fire bricks can be used in contact with molten metals. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation properties. They are commonly used in applications where there is a need to contain and distribute heat, such as in kilns, furnaces, and industrial ovens. When in contact with molten metals, insulating fire bricks can withstand the extreme heat and prevent heat transfer from the molten metal to the surrounding environment. This helps to maintain temperature stability and protect the structural integrity of the equipment. However, it is important to note that the specific type and composition of insulating fire bricks should be carefully chosen based on the temperature and the type of molten metal they will come into contact with. Different metals have different melting points and can have varying corrosive effects on different materials. Therefore, consulting with experts or manufacturers is recommended to ensure the right type of insulating fire bricks are selected for each specific application.

- Q: Can insulating fire bricks be used in the construction of industrial furnaces?

- Indeed, the utilization of insulating fire bricks is viable in the creation of industrial furnaces. These bricks are specifically engineered to endure elevated temperatures and thermal shocks, rendering them suitable for deployment in furnaces operating at exceedingly high levels of heat. Their thermal conductivity is notably low, thereby reducing heat dissipation and enhancing the energy efficiency of the furnace. Moreover, these fire bricks exhibit a lightweight composition and are effortlessly maneuverable, thereby proving to be convenient for construction endeavors. In summary, the superb insulation capabilities and heat-resistant attributes of insulating fire bricks position them as an optimal selection for the construction of industrial furnaces.

- Q: What bricks are thermal insulation bricks?

- Thermal insulation brick is a new type of building material synthesized with macromolecule material. Grey, hollowed out bricks are basically.

- Q: Can insulating fire bricks be used in the construction of lime production kilns?

- Yes, insulating fire bricks can be used in the construction of lime production kilns. Insulating fire bricks are designed to have excellent thermal insulation properties, which makes them suitable for high-temperature applications like lime production kilns. They can help in maintaining the desired temperature inside the kilns and reducing heat loss, enhancing the efficiency and productivity of the lime production process.

Send your message to us

High-Temperature Insulating Fire Brick for Fire Resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords