Fiberglass Unidirectional Fabric Cloth with Density 227gsm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 60000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

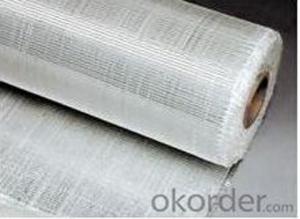

Fiberglass Unidirectional Fabric Cloth with Density 227gsm

Description for Fiberglass Unidirectional Fabric Cloth with Density 227gsm

Fiberglass unidirectional fabric is the product combining the roving in certain angel of 0 ℃ or 90 ℃ with polyester yarn.

Image:

Traits for Fiberglass Unidirectional Fabric Cloth with Density 227gsm

• Fiber straight arranged, fiber strength be ultimately used.

• No powder or emulsion, sink quickly, easy to operate.

• Easy to design, high strength in one direction.

Applications

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: winding, pultrusion, hand lay up, etc.

• Ultimate products: storage tank, tube, pultruded profiles, FRP body of boat, etc.

Specifications

specifications

Fibre type

0°Roving

90°Roving

Overall weight

Width

(g/㎡)

(g/㎡)

(g/㎡)

(mm)

EDW227

E-Glass

—

227

227

1524

EDW350

E-Glass

—

350

350

1524

EDW450

E-Glass

—

450

450

1524

EDJ600

E-Glass

480

120

600

1524

EDJ800

E-Glass

600

200

800

1524

EDJ1000

E-Glass

600

400

1000

1524

Packaging: Wrapped in PVC and placed within a cardboard carton.

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

3.Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q: How does fiberglass mat tissue perform in high temperatures?

- Due to its inherent heat resistance properties, fiberglass mat tissue is highly effective in high temperatures. The mat is crafted from woven glass fibers, creating a durable and sturdy material. These glass fibers possess a high melting point, enabling the fiberglass mat tissue to endure elevated temperatures without distorting or compromising its structural integrity. Unlike other materials, fiberglass mat tissue does not shrink, warp, or become brittle when exposed to high temperatures. It maintains its dimensional stability and mechanical strength, making it suitable for a wide range of applications in industries such as automotive, aerospace, construction, and insulation. Furthermore, fiberglass mat tissue acts as a thermal insulator, providing protection against heat transfer. It effectively resists heat conduction and radiation, assisting in maintaining the desired temperature in a given environment or preventing heat damage to nearby components. Moreover, fiberglass mat tissue is non-combustible, meaning it does not burn or release toxic gases when subjected to fire. This characteristic makes it a dependable choice for applications that necessitate fire resistance, such as fireproofing insulation or protective barriers. In conclusion, fiberglass mat tissue excels in high temperatures. Its heat resistance, dimensional stability, mechanical strength, thermal insulation properties, and non-combustible nature establish it as an outstanding material for demanding environments where elevated temperatures are present.

- Q: Are there any environmental considerations when using fiberglass mat tissue?

- Yes, there are several environmental considerations when using fiberglass mat tissue. Firstly, the production of fiberglass mat tissue involves the extraction and processing of raw materials, which can have a negative impact on ecosystems and contribute to air and water pollution. Additionally, fiberglass mat tissue is not biodegradable and can contribute to landfill waste if not properly disposed of. Furthermore, the manufacturing process of fiberglass mat tissue usually requires significant energy consumption, which can contribute to greenhouse gas emissions and climate change. Therefore, it is important to consider and implement sustainable practices when using fiberglass mat tissue to minimize its environmental impact.

- Q: What is the moisture resistance of fiberglass mat tissue?

- Fiberglass mat tissue boasts a generally high level of moisture resistance. It is typically crafted from tightly woven fiberglass strands, resulting in a dense and water-resistant surface. This characteristic renders it exceptionally effective in situations where moisture exposure is prevalent, particularly in the construction field for roofing, insulation, and waterproofing applications. Furthermore, manufacturers frequently apply special coatings or additives to enhance its moisture resistance, thereby increasing its durability and reliability in wet or humid environments. As a result of this advantageous feature, fiberglass mat tissue finds extensive utilization across numerous industries.

- Q: What is the flexibility of fiberglass mat tissue at low temperatures?

- The flexibility of fiberglass mat tissue at low temperatures is generally maintained, as fiberglass has low thermal expansion and contraction properties, allowing it to retain its flexibility even in cold conditions.

- Q: Can fiberglass mat tissue be used for repairing fiberglass jet skis?

- Yes, fiberglass mat tissue can be used for repairing fiberglass jet skis. Fiberglass mat tissue is commonly used in fiberglass repairs as it provides strength and reinforcement to the damaged area. It is a versatile material that can be used for various fiberglass repair applications, including repairing cracks or holes in jet skis. When applied properly, fiberglass mat tissue can help restore the structural integrity of the jet ski and ensure a durable and long-lasting repair.

- Q: Is fiberglass mat tissue suitable for insulation in data centers?

- Yes, fiberglass mat tissue is a suitable material for insulation in data centers. It provides excellent thermal insulation properties, helping to maintain the desired temperature and prevent heat loss. Additionally, fiberglass is fire-resistant and can offer acoustic insulation, reducing noise levels in the data center. Overall, fiberglass mat tissue is a reliable and effective choice for insulation in data centers.

- Q: Can fiberglass mat tissue be used in structural applications?

- Yes, fiberglass mat tissue can be used in structural applications. It is commonly used as a reinforcement material in composites, such as in the construction of building panels, automotive parts, and boat hulls. The high strength and stiffness properties of fiberglass mat tissue make it suitable for providing structural integrity and enhancing the overall strength of various applications.

- Q: Can fiberglass mat tissue be used for insulating refrigeration units?

- Yes, fiberglass mat tissue can be used for insulating refrigeration units. Fiberglass mat tissue is a lightweight material that has excellent thermal insulation properties. It is commonly used in various applications where insulation is required, including refrigeration units. The fiberglass mat tissue helps to reduce heat transfer, keeping the internal temperature of the refrigeration unit stable and preventing any external heat from affecting the stored items. Additionally, fiberglass mat tissue is resistant to moisture, which is important in refrigeration units to prevent condensation and maintain the efficiency of the cooling system. Overall, fiberglass mat tissue is a suitable and effective choice for insulating refrigeration units.

- Q: Can fiberglass mat tissue be used for insulation in hot climates?

- Yes, fiberglass mat tissue can be used for insulation in hot climates. Fiberglass is known for its excellent thermal insulation properties, which make it suitable for both hot and cold climates. In hot climates, fiberglass insulation helps to prevent the transfer of heat from outside to the inside of a building, thus maintaining a comfortable indoor temperature. It acts as a barrier by reducing the heat transfer through conduction, convection, and radiation. Additionally, fiberglass insulation is fire-resistant, durable, and does not absorb moisture, making it an ideal choice for insulation in hot climates.

- Q: What is the expected lifespan of fiberglass mat tissue in sports facility applications?

- The expected lifespan of fiberglass mat tissue in sports facility applications varies depending on various factors such as maintenance, usage, and environmental conditions. However, with proper care and regular maintenance, fiberglass mat tissue can last for several decades in sports facility applications.

Send your message to us

Fiberglass Unidirectional Fabric Cloth with Density 227gsm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 60000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords