Fiberglass Mat Tissue Unidirectional Fabric 1000gsm 1524mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

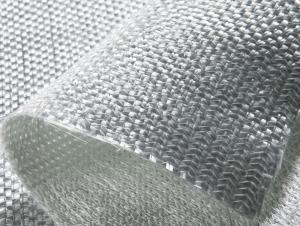

Structure of unidirectional fiberglass fabric Description:

An engineering material, which has many excellent characterstics, such as anti-burning, corrosion resistent, stable structure, heat-isolating, minimum elongated shrinkage, high intensity, etc. This new material product has already covered many domains such as electric appliance, electronic, transportation, chemical engineering, architectural engineering, heat insulation, sound absorption, fire prevention and environmental protection, etc. According to fabric organizational structure and appearance, there are such kind of products: plain weave, twill weave, satin weave, gauze weave.

Main Features of the unidirectional fiberglass fabric:

1)Plain veave,even thickness and low fuzz;

2)High strength in both warp and weft direction;

3)Incombustibility,corrosion resistance and heat resistance;

4)E-Grade Fabric (E-fiberglass Textile Cloth) has excellent electricity insulation property.

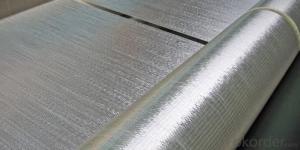

Unidirectional fiberglass fabric Images:

Unidirectional Specification:

specifications | Fibre type | 0°Roving | 90°Roving | Overall weight | Width |

(g/㎡) | (g/㎡) | (g/㎡) | (mm) | ||

EDW227 | E-Glass | — | 227 | 227 | 1524 |

EDW350 | E-Glass | — | 350 | 350 | 1524 |

EDW450 | E-Glass | — | 450 | 450 | 1524 |

EDJ600 | E-Glass | 480 | 120 | 600 | 1524 |

EDJ800 | E-Glass | 600 | 200 | 800 | 1524 |

EDJ1000 | E-Glass | 600 | 400 | 1000 | 1524 |

Packaging: Wrapped in PVC and placed within a cardboard carton. | |||||

FAQ of woven roving:

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: What is the impact resistance of fiberglass mat tissue at high temperatures?

- The impact resistance of fiberglass mat tissue can vary at high temperatures, depending on factors like its specific composition, the manufacturing process, and the testing conditions. In general, fiberglass mat tissue has good impact resistance at high temperatures due to the inherent strength and durability of fiberglass materials. Fiberglass is recognized for its excellent mechanical properties, including high tensile strength and stiffness, which contribute to its overall impact resistance. Typically, fiberglass mat tissue maintains its structural integrity and can withstand impact without cracking or breaking at high temperatures. This is because the fiberglass fibers are designed to endure high temperatures and do not easily soften or deform. However, it's worth noting that the impact resistance of fiberglass mat tissue can be affected by other factors like the presence of additives or binders used during manufacturing. Some additives or binders may decrease impact resistance or make the tissue more prone to damage at high temperatures. To determine the specific impact resistance of a particular fiberglass mat tissue at high temperatures, it's crucial to refer to the manufacturer's specifications or conduct specific tests under controlled conditions. These tests can provide more precise information on how the material will perform under impact at elevated temperatures.

- Q: What is the tear resistance of fiberglass mat tissue?

- The tear resistance of fiberglass mat tissue refers to its ability to withstand tearing or ripping when subjected to mechanical stress or force. Fiberglass mat tissue is known for its high tear resistance due to its strong and durable nature. The tear resistance of fiberglass mat tissue is typically measured and reported in terms of its tear strength, which is a measure of the force required to tear the material. This tear strength is determined through standardized testing methods, such as the Elmendorf tear test or the tongue tear test. The tear resistance of fiberglass mat tissue can vary depending on factors such as the thickness, density, and composition of the material. However, overall, fiberglass mat tissue is known to have excellent tear resistance properties, making it an ideal choice for applications where durability and strength are required, such as in the construction industry for reinforcing materials or in the manufacturing of composite materials.

- Q: How does the density of fiberglass mat tissue affect its performance?

- The performance of fiberglass mat tissue is significantly impacted by its density. Fiberglass mat tissue finds its use in various applications such as insulation, construction materials, and composite materials. The strength, durability, flexibility, and thermal insulation properties of the fiberglass mat tissue are determined by its density. A higher density fiberglass mat tissue generally offers improved strength and durability. This is because a higher density means that more fiberglass strands are densely packed together, resulting in a denser and stronger material. It can withstand higher loads and impacts, making it suitable for applications that require structural integrity, like the construction or automotive industries. Furthermore, the flexibility of fiberglass mat tissue is also influenced by its density. A lower density fiberglass mat tissue tends to be more pliable and easier to shape. It can be molded into intricate shapes and contours, making it suitable for applications where flexibility is crucial, such as boat manufacturing or automotive body parts. The density of fiberglass mat tissue also affects its thermal insulation properties. Higher density fiberglass mat tissue provides better insulation against heat transfer. It effectively prevents the transfer of heat through conduction, making it ideal for insulation purposes in buildings or piping systems. However, it is important to consider that the choice of fiberglass mat tissue density should be based on the specific requirements of the application. While higher density may offer better strength and durability, it also increases the weight and cost of the material. Therefore, a balance needs to be achieved between the desired performance characteristics and the practicality of the specific application.

- Q: How is fiberglass mat tissue used in the production of sports equipment?

- Fiberglass mat tissue is used in the production of sports equipment as it provides strength, flexibility, and durability to the final product. It is commonly used as a reinforcement material in the manufacturing of sports equipment such as snowboards, surfboards, hockey sticks, and tennis rackets. The fiberglass mat tissue is typically layered with resin and other materials, forming a composite structure that enhances the overall performance and longevity of the sports equipment.

- Q: How does fiberglass mat tissue perform in terms of thermal conductivity?

- Fiberglass mat tissue has low thermal conductivity, meaning it is a poor conductor of heat.

- Q: Can fiberglass mat tissue be used for electrical enclosures?

- No, fiberglass mat tissue is not suitable for electrical enclosures as it does not provide sufficient insulation properties necessary for electrical safety.

- Q: Can fiberglass mat tissue be used for making lightweight automotive parts?

- Yes, fiberglass mat tissue can be used for making lightweight automotive parts. Fiberglass mat tissue is a lightweight, versatile material that is commonly used in the manufacturing of automotive parts. It offers excellent strength-to-weight ratio, making it ideal for producing lightweight components without compromising on durability and performance. Additionally, fiberglass mat tissue can be easily molded into various shapes, allowing for complex designs and customization in automotive parts. Moreover, it provides good resistance to corrosion, chemicals, and temperature fluctuations, further enhancing its suitability for automotive applications. Overall, fiberglass mat tissue is a reliable and cost-effective choice for creating lightweight automotive parts.

- Q: How does fiberglass mat tissue perform in terms of dimensional stability?

- The dimensional stability of fiberglass mat tissue is exceptional. This is due to its unique composition and manufacturing process, which result in minimal shrinkage or expansion when exposed to temperature variations or moisture. As a result, fiberglass mat tissue is an ideal material for various applications in the construction industry, where dimensional stability is crucial. It is commonly used to reinforce walls, roofs, and floors. The consistent size and shape of fiberglass mat tissue ensure that it maintains its original dimensions over time, providing long-lasting durability and reliability. Furthermore, its dimensional stability allows for precise cutting, shaping, and installation, reducing waste and increasing efficiency in manufacturing processes. Overall, the excellent dimensional stability of fiberglass mat tissue makes it a preferred choice in industries where accurate and stable dimensions are essential.

- Q: How does fiberglass mat tissue compare to spray foam insulation?

- Fiberglass mat tissue and spray foam insulation are two different types of insulation materials with their own unique characteristics and benefits. Fiberglass mat tissue is a type of insulation made from woven strands of fiberglass. It is typically used in applications where thermal insulation is required, such as in walls, roofs, and attics. Fiberglass mat tissue is known for its high resistance to heat transfer, making it an effective insulator. It is also fire-resistant, which adds an additional safety benefit. On the other hand, spray foam insulation is a type of insulation that is applied as a liquid and expands into a solid foam. It can fill in small cracks and gaps, creating an airtight seal, which makes it an excellent choice for preventing air leakage and reducing energy loss. Spray foam insulation is also known for its excellent soundproofing qualities. In terms of installation, fiberglass mat tissue usually comes in large rolls or batts that need to be cut and fitted into place. It requires careful handling to ensure proper installation and may require the use of protective equipment, such as gloves and masks, as the fibers can cause skin and respiratory irritation. Spray foam insulation, on the other hand, is applied using specialized equipment that sprays the liquid foam onto the desired surface. It expands quickly, filling in any gaps or voids, and hardens within a short period of time. This makes it a more convenient option for insulating hard-to-reach areas or irregularly shaped spaces. When comparing the two, fiberglass mat tissue is generally more cost-effective, as it is less expensive to purchase and install compared to spray foam insulation. However, spray foam insulation provides better air sealing and can offer higher energy savings in the long run. In summary, fiberglass mat tissue and spray foam insulation have their own advantages and are suited for different insulation needs. Fiberglass mat tissue is a good option for thermal insulation, while spray foam insulation excels in air sealing and soundproofing. The choice between the two ultimately depends on factors such as budget, desired insulation performance, and the specific requirements of the project.

- Q: Can fiberglass mat tissue be used for repairing fiberglass truck beds?

- Yes, fiberglass mat tissue can be used for repairing fiberglass truck beds. It is commonly used in such repairs due to its strength, durability, and ability to bond well with the existing fiberglass surface.

Send your message to us

Fiberglass Mat Tissue Unidirectional Fabric 1000gsm 1524mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords