Fiberglass Mat Tissue Unidirectional Fabric 800gsm 1524mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction

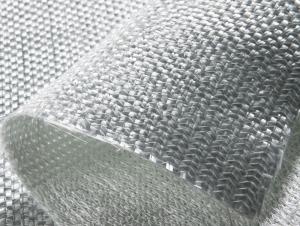

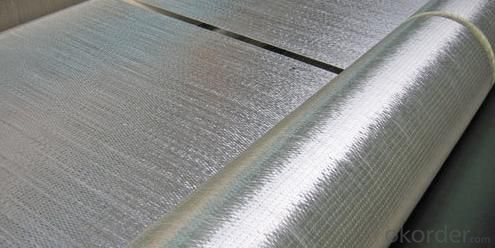

Fiberglass unidirectional fabric is the product combining the roving in certain angel of 0 ℃ or 90 ℃ with polyester yarn.It is mainly used as reinforced materials in the composite material industry.

2.Properties

Fiber straight arranged, fiber strength be ultimately used.

No powder or emulsion, sink quickly, easy to operate.

Easy to design, high strength in one direction.

3.Technical Specification

specifications

Fibre type

0°Roving

90°Roving

Overall weight

Width

(g/㎡)

(g/㎡)

(g/㎡)

(mm)

EDW227

E-Glass

—

227

227

1524

EDW350

E-Glass

—

350

350

1524

EDW450

E-Glass

—

450

450

1524

EDJ600

E-Glass

480

120

600

1524

EDJ800

E-Glass

600

200

800

1524

EDJ1000

E-Glass

600

400

1000

1524

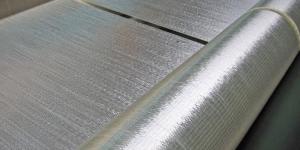

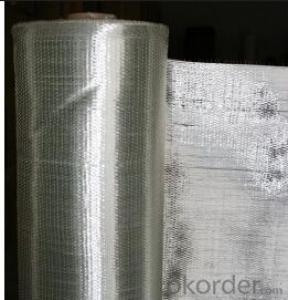

Packaging: Wrapped in PVC and placed within a cardboard carton.

4.FAQ

a. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

b. What is your MOQ?

Our MOQ is one pallet.

c. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

d. Payment terms?

We can accept L/C, T/T etc.

- Q: Can fiberglass mat tissue be used for corrosion-resistant applications?

- Yes, fiberglass mat tissue can be used for corrosion-resistant applications. It is commonly used as a reinforcement material in composite products that require resistance to corrosion, such as pipes, tanks, and structural components in harsh environments. The fiberglass mat tissue provides strength and durability while also enhancing the corrosion resistance properties of the final product.

- Q: What is the UV resistance of fiberglass mat tissue?

- The UV resistance of fiberglass mat tissue can vary depending on the specific formulation and manufacturing process used. Generally, fiberglass mat tissue is known for its excellent resistance to ultraviolet (UV) radiation. The fiberglass strands used in the mat are typically coated with a resin or binder that provides added protection against UV degradation. This coating helps to prevent the fibers from breaking down or becoming brittle when exposed to sunlight. Additionally, the structure of the fiberglass mat tissue itself provides a degree of natural UV resistance due to its dense and tightly woven construction. However, it is important to note that prolonged exposure to intense UV radiation can still cause some degree of degradation over time. Therefore, it is recommended to consult the specific product specifications or manufacturer's guidelines for accurate information on the UV resistance of a particular fiberglass mat tissue.

- Q: Can fiberglass mat tissue be used for making fiberglass molds?

- Yes, fiberglass mat tissue can be used for making fiberglass molds. It is often used as a reinforcement layer to provide strength and stability to the mold, allowing it to withstand the pressures and forces exerted during the molding process.

- Q: Is fiberglass mat tissue suitable for high-temperature applications?

- High-temperature applications are not suitable for fiberglass mat tissue. This type of tissue is usually composed of thin glass fibers interwoven to form a non-woven fabric. Although fiberglass is renowned for its robustness and endurance, it possesses a low melting point, rendering it unsuitable for withstanding high temperatures. Exposing fiberglass mat tissue to elevated temperatures may result in its melting or deterioration, leading to weakened structure and possible malfunction. Consequently, it is crucial to opt for alternative materials explicitly designed for high-temperature applications, such as ceramic or silicone-based products.

- Q: Can fiberglass mat tissue be used for aerospace applications?

- Yes, fiberglass mat tissue can be used for aerospace applications. Fiberglass mat tissue is a lightweight and strong material that is commonly used in the aerospace industry for various purposes. It is often used as a reinforcement material in composite structures, such as aircraft wings, fuselages, and other components. The high strength-to-weight ratio of fiberglass mat tissue makes it an ideal choice for aerospace applications, as it helps to reduce the overall weight of the aircraft while maintaining structural integrity. Additionally, fiberglass mat tissue is resistant to corrosion and can withstand extreme temperatures, which are important factors in aerospace environments. Overall, fiberglass mat tissue is a versatile material that meets the stringent requirements of aerospace applications and is widely used in the industry.

- Q: How does the roll weight of fiberglass mat tissue affect its transportation?

- The roll weight of fiberglass mat tissue can have a significant impact on its transportation process. The weight of the roll determines the ease of handling and the logistics required for transportation. Firstly, a heavier roll weight can make it more challenging to move and handle the fiberglass mat tissue. If the roll is too heavy, it may require specialized equipment or machinery for loading and unloading, such as forklifts or cranes. This can add complexity and cost to the transportation process. Moreover, the weight of the roll also affects the packaging and storage requirements during transportation. Heavier rolls may require sturdier packaging materials and additional precautions to ensure their stability and prevent any damage during transit. This can include using pallets, strapping, or other securing methods to prevent the roll from shifting or falling during transportation. The weight of the roll also impacts the overall cost of transportation. Heavier rolls can increase shipping costs, as carriers often charge based on weight. Additionally, the weight of the roll can affect the number of rolls that can be transported in a single shipment, which can impact the efficiency and cost-effectiveness of the transportation process. In summary, the roll weight of fiberglass mat tissue plays a crucial role in its transportation. It affects the ease of handling, packaging requirements, and overall cost of transportation. Therefore, it is essential to consider the roll weight when planning and organizing the logistics for transporting fiberglass mat tissue.

- Q: How is fiberglass mat tissue used in the production of printed circuit boards?

- Fiberglass mat tissue is used as a reinforcement material in the production of printed circuit boards (PCBs). It is typically impregnated with epoxy resin and then laminated onto the copper-clad laminates. This helps to improve the mechanical strength and stability of the PCB, making it more resistant to bending, warping, and other forms of physical stress. Additionally, the fiberglass mat tissue provides insulation between the copper layers, preventing short circuits and enhancing the overall performance and reliability of the PCBs.

- Q: What is the moisture vapor transmission rate of fiberglass mat tissue?

- The moisture vapor transmission rate of fiberglass mat tissue can vary depending on various factors such as the specific composition of the material and its thickness. However, in general, fiberglass mat tissue has a relatively low moisture vapor transmission rate. This means that it has a relatively low ability to allow moisture vapor to pass through it. This characteristic makes it a suitable material for applications where moisture resistance is desired, such as in insulation or construction materials. However, it is important to note that the moisture vapor transmission rate of fiberglass mat tissue can be further influenced by other factors such as the presence of coatings or laminations, which may enhance or restrict its moisture vapor transmission properties.

- Q: How does the density of fiberglass mat tissue impact its performance?

- The density of fiberglass mat tissue significantly affects its performance. Fiberglass mat tissue is a nonwoven material composed of randomly dispersed glass fibers held together by a binder. The density of the tissue refers to the amount of fibers present in a given volume of the material. A higher density of fiberglass mat tissue generally results in improved mechanical properties and performance. The increased density means that there are more glass fibers per unit volume, leading to enhanced strength, stiffness, and durability. This makes the material more resistant to tearing, puncturing, and abrasion, which is particularly important in applications where the tissue is exposed to harsh conditions or heavy loads. Moreover, a higher-density fiberglass mat tissue offers better thermal insulation properties. The increased fiber content allows for better heat resistance, making it suitable for applications that require thermal protection, such as insulation boards or fireproofing materials. On the other hand, a lower density of fiberglass mat tissue may provide advantages in certain applications. Lower-density tissues are generally more flexible and have better conformability, allowing them to easily adapt to irregular surfaces or complex shapes. This makes them suitable for applications where flexibility or conformability is a primary requirement, such as in automotive or aerospace industries. Overall, the density of fiberglass mat tissue plays a crucial role in determining its performance characteristics. Whether a higher or lower density is preferred depends on the specific application requirements, considering factors such as strength, stiffness, durability, thermal insulation, flexibility, and conformability.

- Q: What is the tensile strength of fiberglass mat tissue?

- Fiberglass mat tissue usually has a tensile strength ranging from 30 to 150 pounds per inch (lb/in). Nevertheless, it is crucial to bear in mind that the precise tensile strength may differ based on the particular type and quality of fiberglass mat tissue utilized.

Send your message to us

Fiberglass Mat Tissue Unidirectional Fabric 800gsm 1524mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords