All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

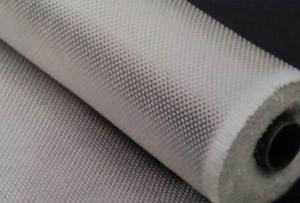

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does the impact resistance of fiberglass mat tissue compare to other materials?

The impact resistance of fiberglass mat tissue is generally considered to be superior to many other materials. Its unique combination of flexibility and strength allows it to absorb and distribute impact energy effectively, making it highly resistant to cracking or breaking upon impact. This makes fiberglass mat tissue a preferred choice in applications where impact resistance is crucial, such as in automotive parts, construction materials, and sports equipment.

How is fiberglass mat tissue recycled?

Fiberglass mat tissue is typically recycled through a process called mechanical recycling. First, the mat tissue is collected and sorted based on its composition and quality. It is then shredded into smaller pieces and cleaned to remove any impurities or contaminants. The shredded material is then melted down and extruded into new fiberglass products or used as a raw material in the manufacturing of other composite materials.

Does fiberglass mat tissue provide structural strength?

Yes, fiberglass mat tissue does provide structural strength. It is commonly used in construction and manufacturing industries to reinforce materials and add strength to various products such as pipes, boats, and automotive parts. The mat tissue is made up of randomly oriented glass fibers bonded together with a resin, which creates a strong and durable composite material.

Can fiberglass mat tissue be used for luggage manufacturing?

Yes, fiberglass mat tissue can be used for luggage manufacturing. It provides a lightweight and durable material that can enhance the strength and structural integrity of luggage. Additionally, fiberglass mat tissue is resistant to wear and tear, making it suitable for use in luggage that may undergo rough handling during travel.

How is fiberglass mat tissue made?

Fiberglass mat tissue is made by mechanically bonding fine glass fibers together using a wet-laid process. This involves dispersing glass fibers in a water-based solution, forming a thin mat on a moving wire screen, and then drying and curing the mat to create a strong and uniform tissue.

Wholesale Fiberglass Mat Tissue from supplier in India

Our team of professionals is committed to delivering high-quality products and exceptional customer service. We understand the unique requirements and challenges of the Indian market, and we strive to provide tailored solutions to meet your specific needs.

Whether you are looking for Fiberglass Mat Tissue for roofing, insulation, or other applications, we have a wide range of products to choose from. Our Fiberglass Mat Tissue is known for its durability, strength, and excellent thermal and acoustic insulation properties.

In addition to supplying top-notch products, we also offer competitive pricing and flexible payment options to make your procurement process smooth and hassle-free. Our sales team is always available to provide you with detailed quotations and answer any technical questions you may have.

Furthermore, our technical support team is dedicated to assisting you throughout your project. From providing guidance on product selection to offering installation tips and troubleshooting, we are here to ensure your success.

As a subsidiary of CNBM, a global leader in the building materials industry, we have access to a vast network of resources and expertise. This allows us to stay at the forefront of industry trends and provide you with the latest innovations in Fiberglass Mat Tissue products.

Partner with us for all your Fiberglass Mat Tissue needs in India and experience the difference that our comprehensive services and superior products can make to your projects. Contact us today to learn more and start a fruitful collaboration.

Whether you are looking for Fiberglass Mat Tissue for roofing, insulation, or other applications, we have a wide range of products to choose from. Our Fiberglass Mat Tissue is known for its durability, strength, and excellent thermal and acoustic insulation properties.

In addition to supplying top-notch products, we also offer competitive pricing and flexible payment options to make your procurement process smooth and hassle-free. Our sales team is always available to provide you with detailed quotations and answer any technical questions you may have.

Furthermore, our technical support team is dedicated to assisting you throughout your project. From providing guidance on product selection to offering installation tips and troubleshooting, we are here to ensure your success.

As a subsidiary of CNBM, a global leader in the building materials industry, we have access to a vast network of resources and expertise. This allows us to stay at the forefront of industry trends and provide you with the latest innovations in Fiberglass Mat Tissue products.

Partner with us for all your Fiberglass Mat Tissue needs in India and experience the difference that our comprehensive services and superior products can make to your projects. Contact us today to learn more and start a fruitful collaboration.