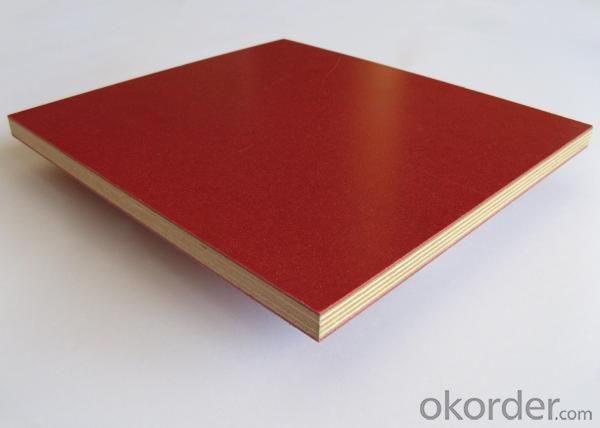

HDO Plywood

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1x40' FCL m³

- Supply Capability:

- 20000M3 Per Month m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of HDO Plywood

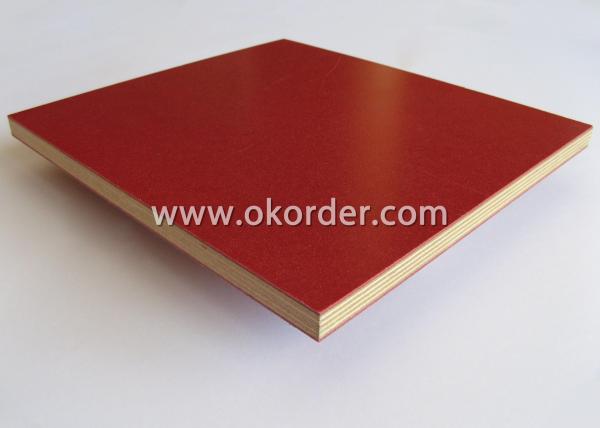

High density overlaid plywood forming panels have greater dimensional stability and smoother, more durable forming surfaces than

nonoverlaid panels. If you want the smoothest possible concrete finish and a high number of form reuses, choose HDO panels.

Their hard, abrasion-resistant surfaces produce a glossy finish, and with reasonable care the panels provide 20 to 50 reuses.

Some concrete forming specialists can achieve up to 200 reuses with careful maintenance of the forms

Packaging & Delivery

1.Packaging Detail: loosing package,pallets package,all can according to customers'requirements

2.Delivery Detail: delivery within 10 days after get the deposit

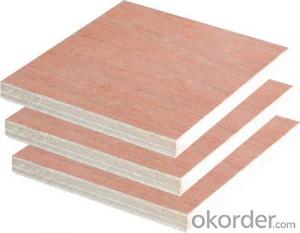

Specifications of HDO Plywood

1220 mm×2440 mm,1250 mm×2500 mm, including other special sizes.

2)Thickness:4-40mm, which is allowed to be adjusted by the customers’ requests accordingly

3)Core:poplar birch combi

4)Glue: WBP, phenolic

5)OVERLAY Surface: imported film 320g/m2

6)Package:Seaworthy packing

7)Usages:can be widely used in construction, furniture decoration, etc.

Advantage of HDO Plywood

1.No wapping, no fracture,not out of shape , it can stay 24hours in boiling water.

2.Good performance and more turnover use time.

3.It is easy to take off the membrane;Time is only 1/7 of the steel mould.

4.Make the surface of concrete more smooth and beautiful,so it can be easy to make decoration and it also deduct the processing of plastering.

5.This can moderate and contact 30% time for a project.

6.Corrosion resistant and ir will nor pollute the surface of concrete.

7.It is good to keep performance warm,ia favorable to make constrution in winter.

8.Products can be made into warping plywood

9.It is better to nail,saw,drill than bamboo and steel mould,can it can be processed into different type

- Q: according to the use of plywood can be divided into needle plywood and broadleaf plywood.

- Ⅲ, Ⅳ plywood moisture content of not more than 15%). ③ quality. Finished products should have rectangular straight edges and obvious edges and corners;

- Q: According to the different composition of the glue, for the construction of plywood with the following types of glue

- According to the environmental protection level, the glue used for plywood can be divided into E0 grade, E1 glue, E2 glue (and even E2 level are not reach the unqualified glue)

- Q: How do I determine if plywood contains formaldehyde?

- The plywood itself is easy to identify because each side can see the shavings that are pressed together, but it becomes hard to find it after making furniture

- Q: What are the processing defects of plywood?

- Patched Plywood Repaired plywood Defects Plywood that has been repaired with a filler or veneer patch.

- Q: Classification of plywood for construction

- if you want to make outdoor use of wood products, you can use E1 (even E0 level) phenolic plasti

- Q: What is the amount of construction works used for this plywood?

- Three types of plywood for moisture-resistant plywood, can be immersed in cold water for a short time, suitable for indoor use at room temperature. For furniture and general construction purposes;

- Q: What are the defects of the plywood?

- The intergrown knots are formed by the tree's live technique. Knots and the surrounding wood close together or with the surrounding wood part of the length of its cross-section than the length of 3/4, hard texture, normal structure

- Q: Material for the plywood defects which

- Decay rot due to the invasion of wood rot fungi, the cell wall material decomposition, resulting in loose wood, strength and density decreased, wood tissue and color are often changing.

- Q: What is medium density fiberboard

- Its thickness specifications are 2.7,3,3.5,4,5,5.5,6,7,8 mm, commonly used specifications are 3,3.5,4 mm.

- Q: One of the commonly used materials for furniture is a wood-based panel

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences

Send your message to us

HDO Plywood

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1x40' FCL m³

- Supply Capability:

- 20000M3 Per Month m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords