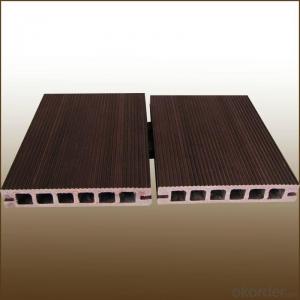

high density HDPE wood plastic composite wpc decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

high density HDPE wood plastic composite wpc decking

一.Product Description:

.

Low flame spread / High slip resistance / No sting of wood / Contains no toxic chemicals or preservatives / Environmental friendly / Can be recycled with 100%

• High Strength

Outstanding screw and nail retention / High impact resistance / Great Compressive-tensile-shear strength / Modulus of elasticity: 20% greater than PVC

• Good appearance & nice touch

Natural feel & wood touch / Broad range of finishes and appearance, Multicolor, and needn't to painting

• Longevity

Its lifespan at least 10-15 years in the outdoor weather condition

• Install & Maintain easily

Easy to produce and easily fabricate / Easy to cut, fix and glue; Easy to tenon, drill and nail / Require less routine maintenance / No need staining & water Sealant

Competitive Price

• Using most advanced machinery to increase the output and reduce the costs.

Strong technical support from famous institute of high polymer to guarantee the best quality as well as cost saving.

• Neighboring one of the biggest wood/ bamboo processing industry region and having a special purchase channel of the raw materials (Plastic and wood/bamboo fiber)

• As a high technology and environmental-friendly enterprise, supports form the government such as reduction and exemption of tax rate are available.

escriptions :

The characteristics of Wood generally had the problem of Waterproof and the serious concern to the environmental protection has been increasing day by day as well as it caused the Governments worldwide to stipulate the law to restrict to fell trees to reach the goal. To satisfy with the market's demand we utilized the characteristics of macromolecule to combine with the high technology of heavy pressure-micro foaming to produce an unique product with the invention and innovation of revolution. We call this new product " CELLwood®".

Properties :

1. 100% recyclable product meets with the environmental protection without

adding any wood flour or sawdust.

2. 100% waterproof.

3. Suitable to be used for the activities indoor and outdoor.

4. The component with high quality features that the density is similar to the wood

(D:0.6~0.7 g/cm3) and light.

5. The processing is similar to the general timber, e.g.: shave, saw, trim, nail, drill,

wash and grind.

6. Strong rigidity and durability. (Similar to teak)

7. Thermal process is easily executed to be blended to have various shapes of the

materials.

二.Technical Data

Slip resistance:

Boards of Techwoodn according to ASTM D2394-05. This is the best ranking for bare-foot slip resistance.

Weathering resistance:

Boards of Techwoodn have very low moisture uptake.This is key for mold and mildew resistance.

UV resistance:

4000 hours accelerated Xenon-arc Exposure,the Boards turned slightly more clear and colored.

Abrasion resistance:

The resistance to abrasion is similar to oak.

Fungus resistance:

Whatever fungus the wood composite is exposed to,it is extremely durable.

Moreover,aging test does not affect this durability.

三. FAQ

. What kinds of wpcproducts do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

四. More picture for your reference

- Q: Pink wall with what color of the floor was warm it

- Brown red

- Q: I saw a lot of things on the wooden floor of the wall, especially such things, I really do not know how to build, I hope you advise more

- The process and shape I have seen, the wood substrate on the line. Use the panel on the wall, do the floor texture of this process is seen! Wall layer after the use of panel wall wall closed edge, the surface can be decorated with paint or varnish of

- Q: Looking at it is not the original sleeping kennel `also deliberately bought a mattress pad pad` `but it must be drilled into the foam no tile on the` `` `` `` `` `` `` ` Tortoise Xiu Lu `` `` `` `` `` `` `` `` `` `` `` `` `` `` `` `` `` `` `

- Three months of the dog is best to keep warm, if the vaccine is also OK, otherwise it is easy to cause a cold and cause dog disease or other symptoms! It is recommended that you buy a cage to sleep at night to keep him up, the sound into the museum called the tortoise both turtle do not let him in the bite of the wind, must pay attention to warm! Be careful, I have suffered in this respect! If adult, he was no problem sleeping on the floor!

- Q: in an home with a dirt floor basement.

- how tall do the 4x4inch posts need to be to work === if I were you I would place the cement block that is made to hold these 4x4's off the dirt .... just count the number of posts needed and go to the wood giants and multiply that number by blocks and

- Q: The floor is buckling up in one spot even though the floor is brand new. I believe the pieces may not be staggared enough to give it the strength to keep it from buckling up. I believe I can re-use alot of the pieces. I think I may have to pull up the floor and reinstall. any other suggestions?

- check the spacing from the flooring to the wall. It sounds there might not be the required 1/4 inch. That is a common problem with laminate floors especially as the summer heat begins to expand the floor. Pull the floor molding in the area it is buckling and see if the flooring is pressed tightly against the wall. If they are, you may need to pull the last pieces and cut them thinner or shorter, then reinstall them. This is not an uncommon issue with a floor that has been installed in the cold without sufficient clearance and now is expanding to the heat of the summer or just the heat of a heated room.

- Q: would sanding floor correct ridges in hardwood floor that happened when contractor tried to correct buckling floor.did' he do poor workmanship but would sanding help.thank you

- This factor usually happens when the foundation floor is not straight , if someone could add extra support from the basement this will even up the floor above, whoever installed your floors was probable off level when they did so, and the only way to fix this would be to remove the boards and work with the sub floor, but .....that's too much work and an extra expense to you unless you still have a valuable warranty , I wouldn't bother otherwise. .

- Q: When laying solid wood flooring how much loss rate is normal?

- Mainly look at the length and width of your house and the width of the floor and the length of the floor and the material, such as your house long 3.64 * 1.22 you buy 910 * 122 board a little waste no ah understand my meaning!

- Q: 800x800 floor tile thickness is how much? If the living room shop 800x800 floor tiles, bedroom shop 1.2 thick composite floor, the bedroom also need to leveling it?

- You can self-test whether the ground is flat, then you can leveling

- Q: Bathroom decoration is to first paste tiles and flooring or to install the first water heater and toilet? Have to say that the next thanked

- Tiles and flooring first

Send your message to us

high density HDPE wood plastic composite wpc decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches