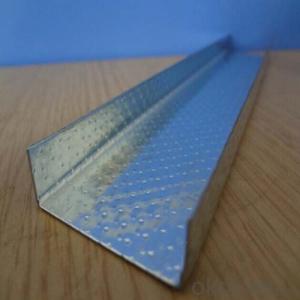

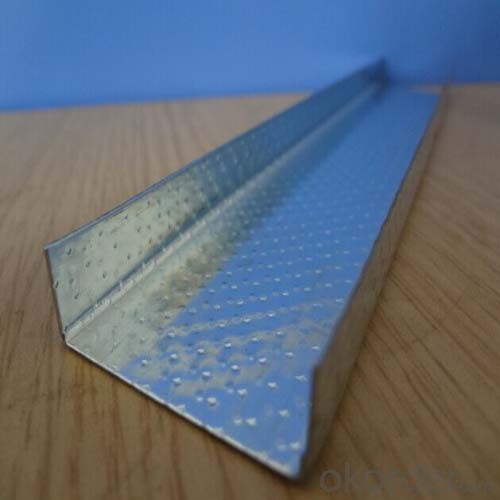

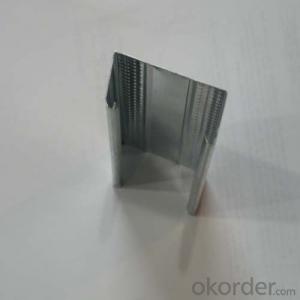

DRY WALL METAL PROFILE OF U CHANNEL ZINC GALVANIZED

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Discription of DRY WALL METAL PROFILE OF U CHANNEL ZINC GALVANIZED

1>adopting high-grade quality hot-dipped galvanized steel,

2>The products surface zero spangle,and intensity toughness, besides, it can add 20% more than common product.

Specification:

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to Australia:

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe, Russia, UKrain, Georgia. etc

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Product Overviews

FAQ

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method. 8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price *large quantity *honesty *good after-service

9.Certificates ISO 9001:2000 Quality management system

- Q:Home improvement in the partition

- Light steel keel, wood keel wall: light steel keel is a substitute for wood keel products, fire effect is significant (when using wood keel to brush fire retardant coating). As a partition wall of the external use of the plate there are gypsum board, Ed panels and aluminum-plastic panels, according to the actual requirements. If you want to do noise effects, in the middle of the installation of rock wool or mineral wool sound-absorbing panels;

- Q:Light steel keel partition wall fire retardant coating shabu several surface

- Best four times, at least twice. I hope my solution will help you

- Q:What kind of new material is now called a "light partition" in the house? Is it safe?

- As for the sound insulation performance, and not because of the wall is light and affected, but higher than the national noise standards, light steel keel of the outer package with noise pad, can play a very good sound insulation, and the same thickness of the concrete slab The sound insulation of the partition is only 32 decibels. According to the authority test, light steel keel inorganic composite board partition can block the noise reduction of about 38 dB, significantly higher than the international standard of 30 dB, more to ensure the comfortable living needs of living.

- Q:Gypsum board wall above the good paint glass?

- Gypsum board partition wall construction operation process: (1) According to the design drawings, in the already done walls, floors, the ground release off the line, the door hole edge. (2) according to the design drawings and the actual size, with a wheel cutting machine cutting keel and classified stacking. (3) according to the line has been put away and the door edge, with nails or expansion bolts to the ground keel fixed on the ground floor, nail or expansion bolt spacing 600mm. The top of the keel into the wall of the reserved hole 100mm, and then use cement mortar packing fixed, or with nails, expansion bolts to the end of the handle along the top keel fixed to the wall. (4) According to the cut line and the edge of the door, according to the size of the file size layout, painted in the edge, along the top keel, less than the modulus should be placed in the partition with the wall at the first board. (5) According to the document mark will be cut in advance of the length of the vertical keel in turn inserted along the edge, along the top keel groove, the flange towards the direction of the proposed panel to be installed. Adjust the vertical, positioning accuracy, with rivets fixed. The vertical keel on the wall is fixed to the wall with a nail or expansion bolt, and the distance between the nail or the expansion bolt is 1m. (6) the installation of doors and windows to strengthen the installation of the keel: the first installation of the hole on both sides of the vertical reinforcement keel, and then install the hole up and down to strengthen the keel, and finally install the big hole on both sides of the upper and lower reinforcement keel and bracing. (7) Install the cross brace and support card. The vertical keel fastened, so that the entire partition keel has sufficient strength and stiffness.

- Q:Light steel keel gypsum board partition wall construction practices and construction process What is the difference?

- The practice is to first play on the ground and shed on the corner keel must be vertical after the installation of the main keel times the keel installed in the plaster board plaster brush latex paint difference is stronger than the keel cost is higher than the wood keel

- Q:Light steel keel wall cheap or cheap red brick

- Now the sand is soaring, if the area is large, short-term is certainly selected light steel keel, if it is their own long-term use, it is still a brick, expensive on your point!

- Q:Decoration decoration works Light steel keel wall, layer 4 meters high thickness What are the requirements? There is no specific specification?

- Environmental effect is obvious Light steel keel wall built-in steel components of a one-time welding and ridge installation, to avoid the construction site long-term dirty situation, in line with the social needs of energy-saving emission reduction, with significant environmental significance.

- Q:Light steel keel wall can be installed sliding door

- 940 door to install the sliding door a bit small, open only less than 500 after the space, I suggest you install the folding door

- Q:Light steel keel + gypsum board + surface brush latex paint partition wall per square meter offer is how much?

- Different local prices are different, but now artificial up, 150 may not find, there is a problem, that is, those who labor market, in general, the level is quite not how!

- Q:Light steel keel gypsum board wall height is how to determine

- There is no specific rigid provisions, the specific height according to the actual situation to the scene. Light steel wall commonly used for each root is 3 meters long, if the actual height beyond too much, you can order.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

DRY WALL METAL PROFILE OF U CHANNEL ZINC GALVANIZED

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords