Perforated Lay on Aluminum Ceiling panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | Place of Origin: | Brand Name: | |||

| Model Number: | Function: | Feature: | |||

| Ceiling Tile Shape: | Ceiling Tile Type: | Surface Treatment: | |||

| Metal Ceiling Material: | Key word: | Specification: | |||

| Height: | Thickness: | Perforated diameter: | |||

| Color: | MOQ: | Delivery time: | |||

| Packing: | Certificate: |

Packaging & Delivery

| Packaging Detail: | Aluminium ceiling tile (Lay in) -------------------------------------------------------- 18pcs/carton carton size:625x625x225 340carton/20ft 3182.4m2/20ft 760carton/40HQ 7113.6m2/40HQ Aluminum ceiling Lay in tiles -------------------------------------------------------------- 26pcs/carton carton size:625x625x225 340carton/20ft 2203.2m2/20ft 760carton/40HQ 4924.8m2/40HQ |

| Delivery Detail: | 10days |

Specifications

2014 New fireproof aluminum ceiling

Specification:600*600

Material: Aluminum alloy

Certification:ISO,BV, TUV

Factory price

DESIGN FLEXIBILITY CMAX ceiling panel appearance provides interesting possibilities for spatial room designing. The ceiling panel show different style pattern and shape, which engage you match your design. A range of colours and finishes is standard available and special colours upon request.

EASY PLENUM ACCESS The panels can be easily demounted by hand allowing easy and full access to services and installation in the plenum.

DURABILITY Square panel ceilings are manufactured from durable roll formed aluminum (0.5/0.6mm) or steel0.5 mm coil,finished with a polyester paint to provide a long ,low maintenance life .

Product characteristic: 5)Function: Acoustical, Fireproof, Waterproof, Washable, Light reflect, |

1) Our clip in aluminum ceiling:

Clip in square ceiling, widest applicable among all type of ceiling with outstanding advantages. Plain or pattern can be selected according to the actual requirement. Clip in system which is concealed, steady structure, flat surface, could be both used as ceiling and wall panel.

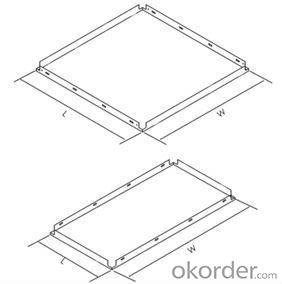

2) Specifications:

| Specification | Thickness | Height | Legend |

| 300×300mm | 0.4-1.0mm | 19mm(short edge) 25mm(High edge) |  |

| 300×450mm | |||

| 300×600mm | |||

| 300×1200mm | |||

| 400×400mm | 0.5-1.2mm | ||

| 500×500mm | |||

| 600×600mm | |||

| 600×1200mm | |||

| Base materials | Aluminum alloy, the grade of aluminum alloy can be selected according to the actual requirements; Besides, galvanized iron and stainless steel material is also available | ||

| Surface treatment | Powder coated(ordinary powder, Polyester powder), Paint coated, Film coated | ||

| Type of Surface | Plain plate or perforated plate is selected according to the actual requirements | ||

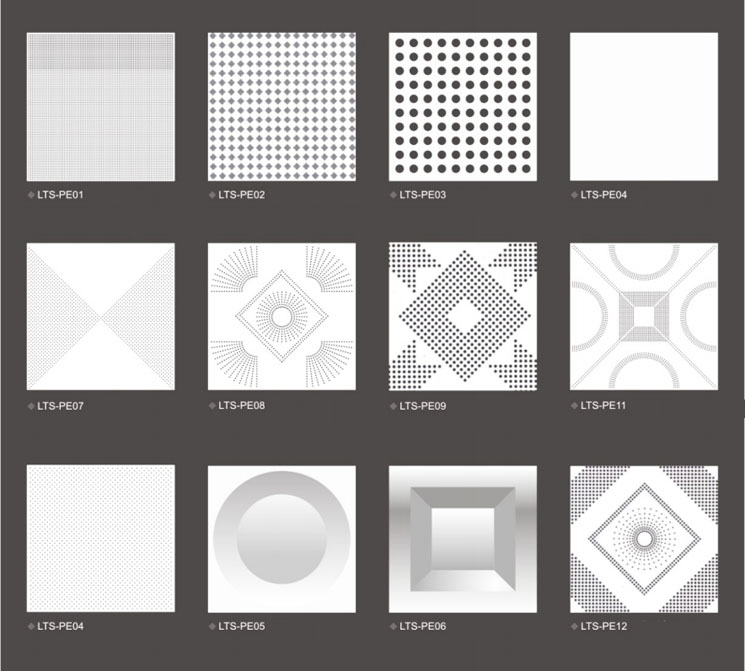

3) perforated pattern:

Perforation is a kind of processing technology for metal ceiling.Ceiling design beautiful patterns according to the arrangement of perforated holes with powerful sound absorbing and isolating effect. Rators possesses over 40 kinds of fixed perforated types, and could be customized according to client's requirements on patterns, sound absorbing to meet the actual situation.

4)Our Packing:

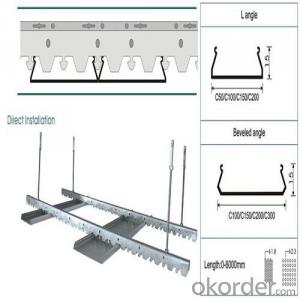

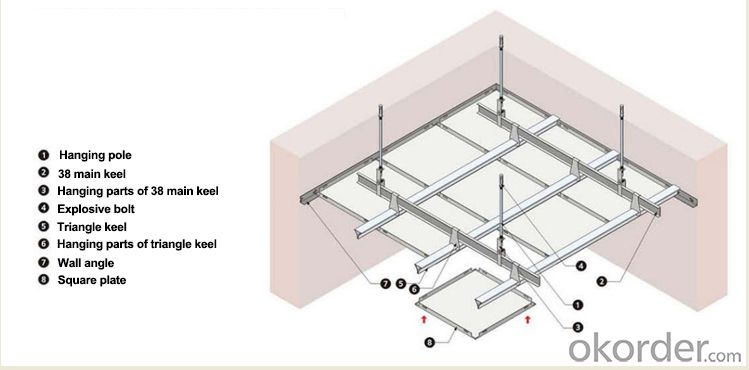

5)Installation Method:

The upper main keel and lower triangle keel are tightly connected with "cross" structure,therefore,it can assure the levelness of whole suspended system with more solid structure.

6)Sample Project:

7)Application:

mainly used in project for big area with soundproof requirements, such as hotels,stores,office building, hospitals,railway stations,metro stations and so on.

8)Certificate:

ISO9001:2008, BV,TUV, Product Quality Certificate.

9)Factory Tour:

- Q:The designer advised us to use the gypsum board on the toilet, said nice, the atmosphere. Because we are in the top floor, does not affect the leakage, we first decoration, good tangled, such as gypsum board, then the cost will be much higher? Please experts to give advice.

- I was decorating, the bathroom ceiling never used gypsum board, the bathroom water vapor weight, gypsum board will suffer after damp

- Q:Do you want to use the top angle of the ceiling?

- Used to look better.

- Q:How many pieces of aluminum slabs are used for the integrated ceiling

- 5 pieces 20cm multiplied by 1m = 1m?

- Q:Buy lights on the Internet, people say that I should buy a suitable ceiling for the integrated lights, is this going on?

- Integrated ceiling is used aluminum plate, mainly with the plastic plate to distinguish that only

- Q:600 * 600; 300 * 300; 300 * 600 specifications of the price of aluminum plate how much?

- Depends on the thickness and brand, then the coating is fluorocarbon or other. Ordinary in 45 yuan per square, fluorocarbon will be more than 100. Suggest a friend to accompany you to buy.

- Q:Can the aluminum plate be cut and installed?

- Kouban can be cut to install, the buckle is stuck in the metal card above the no problem, the direction of the cut is best horizontal, vertical a little problem.

- Q:Are there any differences between striped aluminum slabs and aluminum bars?

- Aluminum plate is the size of the disk saw is generally 80, 60 or 90, the length is generally between 100CM ~ 300CM, the entire board was strip of aluminum. Aluminum slab plate is based on aluminum alloy sheet, through the open material, shear angle, molded into the aluminum plate surface using a variety of different coating processing to get a variety of aluminum plate products.

- Q:Buy aluminum plate, need to pay attention to what

- Some businesses use the method of fraud to reap huge profits, such as your order is the film, he installed you is pearl roll coated plate, because the two kinds of surface looks really not a good difference, but the price is Big difference. There are two ways to identify, one is to use the lighter to blacken the board, the film is easy to wipe the black stains, and how to rub the roller will leave traces; another method is to use sharp objects, We can see the different scratches come. It is best to write in the terms of the contract claims.

- Q:Aluminum cords hanging ceiling and plastic buckle ceiling which is good?

- First, the demolition, installation, maintenance are convenient, easy to install lamps; ?????? Second, the aluminum plate hanging ceiling waterproof, high temperature resistance than plastic top good; ????? Third, aluminum slabs look good, modeling can be parquet and other choice of space, and plastic is relatively no choice for a lot of room.

- Q:Ready to give the room ceiling, with aluminum slab board, the type looked a little dizzy, the surface point of view, drawing board can clearly understand, that kind of film and anodized plate also how to read the plate can not read, Experts how to distinguish between these types of aluminum slab material, as well as anodized plate price of the money more appropriate, the price of roller coated more money appropriate, thank you

- Rolling plate is the surface of aluminum substrate for degreasing and chemical treatment, the roller coated high-quality paint, dry curing from. The base material is the same as the laminates. Through the high-performance roller coating process, can more effectively control the accuracy of the plate, flatness, the successful elimination of the traditional led to the bumps and wrinkles, so that the architectural decoration color uniform and delicate, soft and bright, according to the use of different coatings and roller method quality There are some differences. Its surface of the film thickness than the film is thin, only 0.04mm, so the regular roller coated boards are generally thinner than the same specifications of the film board 0.1mm. However, due to the use of roller coating process, it is less likely to produce color than the film. Relative to the film is very soft reflective, good cleaning, and difficult to scratch discoloration, but the price is high.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Perforated Lay on Aluminum Ceiling panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords