XBD Double Suction Split Case Fire Fighting Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

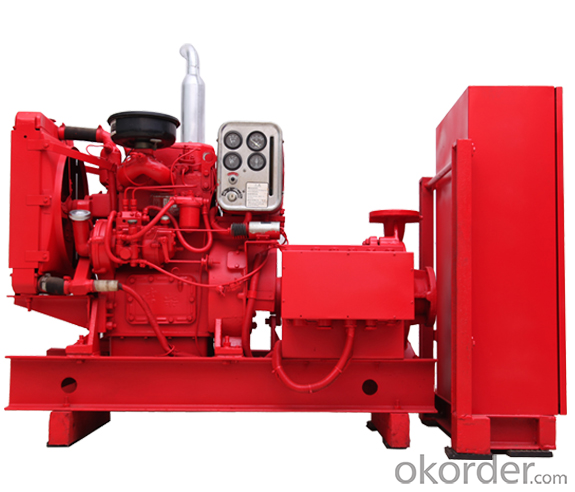

XBD Double Suction Split Case Fire Fighting Pump

Basic Info. of XBD Double Suction Split Case Fire Fighting Pump

Model NO.:XBD series

Pump Casing Combined:Horizontal Split Pumps

Impeller:Closed

Working Pressure:Low Pressure Pump

Position of Pump Shaft:Horizontal Pump

Usage:Pumps

Impeller Number:Single-Stage Pump

Influent Type of Impeller:Double-Suction Pump

Mounting Height:Since Irrigation Centrifugal Pumps

Color:Blue

Export Markets:Global

Additional Info.

Packing:Plywood Cases

Standard:CE; ISO9001

HS Code:8413709990

Production Capacity:50000 Pieces Per Year

Product Description of XBD Double Suction Split Case Fire Fighting Pump

The water pump group driven by diesel engine for emergency / fire fighting is a high-tech product It is integrated with microprocessor and computer technology, industrial automation control technology, telecommunication technology, modern mechanical design and manufacturing technology, etc. It is very strong in professional technology. It has the best specialists with ability in the field of computer and automatic control system in China. It has supplied multiple computer control systems for both domestic market and abroad. These systems, highly modernized and intelligent, have reached an advanced world level.

XBC series water pump group driven by diesel engine for emergency is mainly applied to high temperature cooling water system. These are the iron melting furnace, the iron alloy electrical stove, the crystal equipment for progressive casting, the heating furnace in steel rolling, the converter smoke cover and so on. The pump group also can supply cooling water to reactor. This equipment is very important because it is the last protection stage for the reactor.

XBC series water pump group driven by diesel engine for fire fighting is mainly applied to the supply of production and fire protection water in different fields, such as power plant, chemical plant, high building, grand restaurant and hotel, airport, business building, gas station, and coal gas station etc. By considering GBJ45 -82 fire protection requirements, the water pump group driven by diesel engine for emergency/fire fighting must be used in high buildings, so it has a vast market prospect.

XBC series steady pressure water pump group driven by diesel engine for fire fighting is mainly applied to those water supply stations where automatically steady pressure is needed. The pump can start and stop automatically to maintain the presetting pressure. It is controlled by PLC which processes the signals coming from the pressure meter. The steady pressure pump and the fire protection pump are on standby with each other.

These groups are widely used by chemical plants and power plants, both domestically and abroad.

FAQ

Q: Are CNBM pumps available in DIY stores?

A: Yes, currently, we’re available for DIY stores all over the world.

Q: Where do I have to send pumps for service?

A: You must send them to the CNBM PUMP Service Point or, after contacting Customer Care, to the CNBM PUMP service center in China.

Q: Are your pumps acid-proofed?

A: To choose the right pumps for chemical applications, we do need further details on hydraulic operations as well as on the type, concentration and temperature of the liquid.

Q: Can your pumps mount Eff.1 motors

A: Currently, only on request though this will shortly be a CNBM standard.

Q: Are your pumps protected against dry running?

A: No, unprotected centrifugal pumps are not generally designed for dry running. It is important to give us or your dealer as much information as possible about the system in which the pump is used. Inlet pressure, the type of liquid to be pumped, together with relative density, viscosity and temperature, for example, are required in order to allow CNBM to recommend the right pump with the right gaskets for a long operating lifetime.

Q: How can I get trained on CNBM products?

A: Yes, we provide training courses in our factory (products, general and specific pump technology, hydraulics, and practical applications). Please consult your sales manager or get in touch with our headquarters for more information.

- Q: my basement flooded and the water came in contact with the wiring on my water pump.Now the pump tries to turn on but shuts off without pumping any water.How do i get my pump pumping water again?

- What kind of pump (ie sump,submersible,shallow well).If it just hums and the shaft doesn't turn its probably the capacitor($25 at johnson controls) or it could be one leg of your 240v breaker tripped(check voltage at breaker and wiring)

- Q: What is the definition of the pump in the capacity of the pump?

- Work pump, spare pump, repair pump three are interchangeable use, the work pump need to overhaul, repair pump work, work pump is maintenance pump. The capacity of the water pump is not less than 25% of the work pump. If the work pump, spare pump, repair pump model is the same, the work pump 4 units, repair pump at least 1 units, 5 pumps, repair pumps need 2 units

- Q: Today I was installing a new water pump on my 1999 grand Prix. When tightening the bolts one of them snapped off. Now the pump leaks from that broken bolt. I was wondering if I would be able to stop the leak using some sort of sealant or would I have to take the car in to get the bolt removed?

- The bolts around the pump have several reasons and one of them is for proper mounting, another is when engine cooling system and block expand when engine is running gaskets dont leak, ect. Yes, that bolt has to be removed, so that bolt hole can be used. If you have enough mechanical ability to remove and replace the pump, with the proper tools, you could do it.

- Q: replaced one themostat, disconected lower unit twice look at the water pump everything looks fine but when lower unit was reconnected water pump would not work. not sure if asembled it wrong or forgot to d somthing. can someone help.

- You miss aligned the Pick UP tube with the lower unit, drop the unit, and watch from the bottom to make sure the hose hits the PICK UP tube !

- Q: I was vacuuming up water from my basement I assumed was from the rain, suddenly water started spraying out of a blue pump at the base of my furnace, don't know what the pump does or why its spraying but its making an awful mess.

- Blue pump, usually found on the floor near the furnace (sometimes mounted where plenum meets the furnace frame) is a condensate pump. One of the products of combustion is water. This water is drained from the ventor motor (a motor which runs and sets a artificial draft inside the combustion chamber) to a drain nearby or a electric pump which then pumps the water over a longer distance to a remote drain. If the pump's discharge outlet gets plugged from dirt the result is usually the mess you see. Remove the cover plate of the pump housing, clean it out and run a wire with a small rag attached as a snake through the tube to drain. There is usually some type of float switch inside the pump housing so make sure it is free to move. Check for operation by pouring some tap water in it and move the float switch to on (up) One final note and this is very important. If the pump or tube to drain is filled up with a crud that resembles paste, call your local trusted HVAC tech for furnace service. This condition can be an early sign of heat exchanger failure and is a major safety concern for your family

- Q: Water pump

- You okorder /

- Q: About how to calculate the pump installation height?

- Best to find water pump manufacturers, their own bad count. Sometimes is not necessarily correct, which is related to some parameters of the pump itself, with bad cavitation

- Q: We had a thunderstorm followed by power outage last night, this morning I went to use the water and it slowly went dead.I began by inspecting the pressure tank and pressure control switch, then found the outside water pump breaker was tripped, upon resetting the water was back on!But wait, after about 1-2 minutes of use there was a small quot;POPand smoke from the control switch and the breaker tripped again. It seems now that every time the water pump kicks in I've got a 50/50 shot of the circuit breaker blowing. I'm not sure what to do now, I don't want to keep resetting my pump breaker, we really didn't get that much rain so I don't know what would be causing this issue?Any help would be greatly appreciated.Thanks!

- Sounds like an electrical short in the control switch (where, you indicated, it was smoking) that is tripping the circuit breaker. It could be something as simple as an insect nest inside the switch housing causing a short, or a broken terminal connector. De-energize the circuit and repair the short or replace the switch.

- Q: for a school project, i need to boil cold water using a vacuum pump. I did some research, but i still didn't find what i needed. I need to know what kind of pump i need for this, and where i can get one for cheap, since i will only use it for this project. if you know how to actually use it, you can throw that in as well. thanks!

- I'm not telling you it all but you can take an A.C vacuum pump and it will lower the boiling point of the water where it will boil at only 65 to 75 degrees Ferlinghetti

- Q: Work done in water pumping?Water is to be brought from a well 60 meters bellow ground level to a tower 10 meters high, once there the water falls freely on a 5000 liter tank. A submerged pump 10 meters under water level and a two inch diameter pipe is to be used. What is the work done by the pump when 2000 liters have been served to the tank; what is the power of a pump selected to do this work in 20 minutes.

- Power_W = (Mass_kg * Gravity_m/s/s * Height_m) / time_s Where: Mass kg is 1kg/l of 2000 liters Gravity is 9.81m/s/s Head is 60m + 10m (height). The suction head is ignored because the pump is submerged. In practice there is some suction head due to intake restrictions like pipes, check valves, strainers. The time is 20 minutes in seconds. The work is the energy used in the time allocated, which is: power * time in seconds, which is watt seconds = joules. Not needed here as it is in the formula above. Power is the rate of doing work. The depth below water is not really relevant except for pipe losses which increase the head slightly. The flow is 2000 liters/20 minutes = 100 l/min. This can be used with the head of 70m to determine the pipe restriction, which amounts to a pressure drop representing extra head added. It will indicate whether the pipe is too small (excessive head added) or whether the pipe is overkill (no head added). You can find on line calculators for this, e.g. search pipe resistance flow on line calculator. I am guessing a 2 inch pipe has little loss at this flow. This is the so called water power. It is the output power of the pump. The pump may only be 50% or so efficient, so the mechanical power delivered by the motor needs to be greater by this ratio. The electrical input power to the motor is greater again to allow for motor efficiency. This might be 60-90%. In practice the efficiency of pump and motor are determined from user manual or specification of the actual devices with the actual loads (head and flow).

Send your message to us

XBD Double Suction Split Case Fire Fighting Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords