Woven 3K Square Carbon Fiber Tube Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 watt

- Supply Capability:

- 30000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction for Carbon Fiber Tube

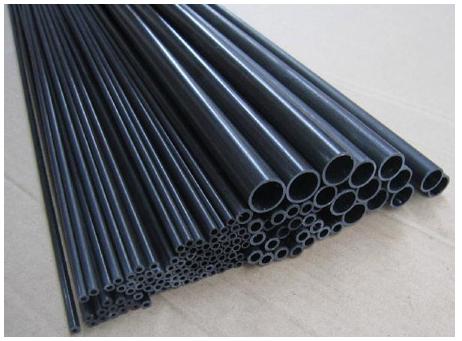

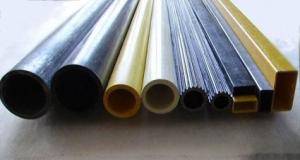

♦These 3K Carbon Fiber Tubes Carbon are made of pure carbon fiber with beautiful twill weave

♦ Available in different colors and sizes.

♦ Customized specs are accepted.

2.Typical Features

♦ Low weight

♦ High strength

♦ High temperature resistance

♦ Abrasion resistant

♦ Good toughness

♦ Resistant to aging

♦ Anti static

♦ Conduction of heat,etc.

3. Technicial Process

Winding forming technology is a kind of products molding method to use presoak tape to roll on winding

machine with heat , he principle is making the fabric soften and making the resin of fabric molten by the hot roll

of winding machine,under a certain of tension, in the operation process of the roller, with the aid of friction

between the roller and the core mold to make the tape rolled continuonly on the core until reach the needed

thickness, then after cooling of the cold roll to finialize the disgn,take it off from the winding machinek,and put it

into the curing oven to curing, remove the core mold after curing and the products is finished .Winding pipe

has the advantage of high strength , high straightness ,and can make tapered tube the

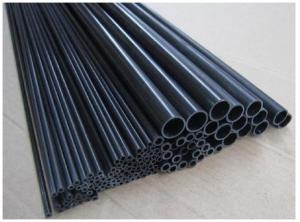

4.Photos

- Q: Can you put auto locks in a 2001 sunfire that before didn't have any

- Don't use pvc. Cpvc or pex is the better choice. Pex is faster to run and the fittings are crimped on.Cpvc takes longer a needs the glue to set up before turning on the water, but is cheaper and easier than copper.

- Q: ya know the really cute hairstyle with the little bump on the top of the head. yeah, il love that but i SUCK at it. like EVERYtime i try to do it, i screw up and it comes out ugly and even. i just need somebody to direct me to a web site or to give me diredctions themselves on how to do it. please help me!

- this is just the tip of the iceburg. there has been so much wasted in Iraq its ridiculous

- Q: All the fire extinguisers in my home are about 9 years old. They all still show they have a full charge. I'm just wondering, generally speaking, how long these are good for before they need replaced. The original box doesn't say. Is it safe to assume that as long as they show they have a full charge, they are still good affective?

- Sounds like you are getting into some work. If you want to break the concrete away with a sledge hammer or a jackhammer (depending on how much you need to break away), to replace all the pipe with PVC. I think the best way for you to do it is to cut the metal pipe close to the concrete, let about 2 inches protrude, and then connect it to the new PVC with a Fern-co fitting, this is a rubber fitting with hose clamps on both sides. You will need to know the diameter of the two pipes you are trying to connect, I do HVAC and plumbing for a living, and have used these fittings countless times and they always worked for me, a life saver sometimes actually. I hope this works for you and let me know if I can help in any way.

- Q: No Legendary fire types I can get any fire type the rest of my team: Milotic Hydreigon Archeops Conkeldurr Gardevoir

- i prefer the beach or a pool. the fire hydrants in my city have a special lock on them so people cant open them. Home Depot.

- Q: k so i know this is bad, but i need some info on alarm systems to sneak out. The alarm is set everynight, and idk the code, how can i get out of a window without triggering the system?

- This Site Might Help You. RE: Why does my knee lock up? I've had this problem for a little while, and I figure I try to figure out what's going on. So what happens is I'll be bent over, normally in a squatting position, but sometimes just sitting with my knees bent, and I'll go to get up and get hit with this shearing pain because I try

- Q: Has anyone ran these tires before?How they work in snow/mud/ice/slush/off road?They are studdable so do i really have to have them studded? If I get them studded for the winter months, then in the spring is it possible to get the studs removed?

- No because you are not parked you are abandoning a burning vehicle which is legal no matter where you happen to be.

- Q: can I use Microsoft access for my website's user login credentials ?

- I would go with the 3/4 all the way. You only have 3/4 supply so go that.

- Q: I'm retrofitting my air conditioning. my lines are full of this slimey green goo, which smells like lime. what is it? is this bad?? do I need to replace everything??

- Sounds like an oil seal! Could be the main seal at the shaft or just a gasket going bad. Have you tried searching youtube videos for information? This can be a big help. Order yourself a repair repair manual that you can refer too. That would be the first thing I suggest if your going to do it yourself. You might even be able to find some repair images right here online. So your leaving a red transmission fluid not a black oil correct? If it's black and between the engine and tranny it could be a main seal there.

- Q: I have a pathfinder with an annoying alarm. If I take ou the Horn fuse will the alarm stop going off. It is SOOO loud that people at work and in my apartment complex want to gag me and kill me - but don't want to pay 50 bucks to have it shut off. Or what fuse number would it be?? It was already there and i bought it used, so there's not a manual.Thanks for any feedback!!!

- The costs of the materials is easy to figure. If you use flex pipe then it should be about $20.00 for the flex pipe and then there are the fittings at $5.00 per end, and a valve if they can not reuse the old one. But you may be required by code to use black pipe, then both the labor and materials will be a bit more. Local building codes vary especially if you live in Chicago (stricter codes - unneeded by unions). Then you have the question of labor. Are you going with the joists or perpendicular to them?. The labor should not be more than a couple of hundred. But is this a part of the overall project or do you need to have a separate plumber come in for the job? It is more if not a part of the original estimate and a different contractor needs to be called in that was not scheduled. All in all you should be able to get this done for less than $300.00. It could be as cheap as $100.00 You have a lot of variables that come into play.

- Q: crappy will i get in trouble by the fire fighters if i paint it the same color . thankx

- Greetings from the northern plains, with not the least bit of amusement over your suffering what we've always dealt with. First, to get it out of the way, do not call this guy back again, as he is ripping you off. I believe it's called profiteering, like the bastards that would spike the price of plywood to $100 a sheet before, or after, a tornado or hurricane. (I would perhaps make this a hobby to go after the guy, his reputation, and his business, as he is one low-life dude, and I can be nasty.) Nuff. Drain cleaning chemicals are intended to dissolve, or at least loosen, clogs such as grease, hair, soap, etc., but not ice. Yes, ice can form in drain lines, especially if not nicely sloped (where there's a sag in a straight run), or at a fitting. Once started, it can accumulate - that's how icicles are formed, a little a time. If the drain pipe leaving the kitchen (likely 1 1/2 pipe) is enclosed above the garage, I'd open up the garage ceiling (if finished), or perhaps the chase it's boxed in with, and warm the pipe with hot air, to get things going. Once done with that, get some insulation under the pipe (in effect getting the pipe into the envelope of the house, not below it). I agree that the yellowish leak may well be the drain cleaner, but the leak also betrays - a leak. Any and all fittings should be inspected. Worst case is actually a cracked drain pipe from the ice, and steel drain pipe (very not likely). PVC or ABS plastic drain pipe is quick and economical to cut out and repair, so buck up. (Personally, I would also exit with an access panel for the next time, not just sealing up with a drywall repair.) In the coldest climates, some might use pipe heating tape as a preventative measure, but I suspect you aren't in one, just caught in this nasty weather. The tape, however is not a good solution to an already-frozen line - it's too slow.

Send your message to us

Woven 3K Square Carbon Fiber Tube Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 watt

- Supply Capability:

- 30000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords