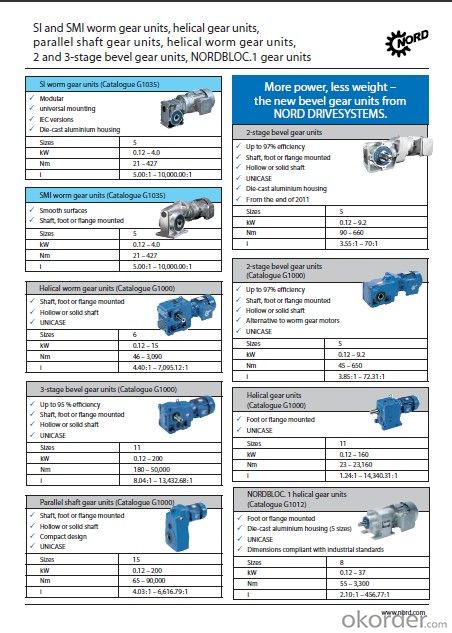

Worm gear units

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Im tryin to do a little home experiment. I want to know the detailed steps to turn an ac or dc motor into a power producing generator. I dont wanna pay for info so any links to free websites with details on this subject would be appreciated. Nothing complex explaining voltage and stuff like that just the actual pieces i need to add replace or remove for power production. thanx

- Ac Motor Generator

- Q: Why do motors need capacitance when they start?

- A positive reverse circuit. The switch hits the top. "Yes" is to string the capacitor to the coil below. The switch "hit" below is the series of capacitors connected to the coil above. There is no need to consider the capacitor charging problem.

- Q: difference between Ac and DC electric motors?

- simple ac means alternating current dc means direct current

- Q: I'm confused - Does an induction motor used for an automobile convert DC battery power to AC? I'm under the impression that induction motors need AC power to run, so how can this quot;ACquot; motor use DC power to make AC? I'm aware that there are AC/DC inverters but wouldn't that make the whole system less efficient since it has to run through this extra device to make power?

- There are no AC motors in an automobile. DC power is produced in an automobile by an alternator. An automobile alternator is a 3-phase, wound-field synchronous generator that converts mechanical power from the engine to AC power. The AC power is converted to DC power by s simple rectifier that is usually mounted inside the alternator.

- Q: What are 3 purposes of the split rings on the commutator? What is the difference between a DC and an AC motor? explain.

- The commutator is made of segments. This is what causes the magnetic field to change polarity as the armature turns and so maintains an opposite force between the armature and field. A universal motor has a commutator and can be used on ac or dc. Some dc motors are permanent magnet motors and cannot be used on ac. Another family of motors is induction motors. These can only be used on ac and don't have the commutator, in fact there is no electrical connection (usually) between the rotor (rotating armature) and the stator (static field). The ac terms were derived from dc since motors were first made only for dc.

- Q: i would like to use dc motor against 10hp Ac motor for my 100 ton power press

- None of this makes sense. If you want a 100ton press, you need to use Hydraulics. To use motors, would require very large, high voltage motors, or very large gears.

- Q: Provide the difference between basic working and mechanical differences of these both types.And if you can then please also provide good online resources for diagram and mechanism. Thanks

- DC motors have brushes, and AC motors do not.

- Q: I don't want to blow out a fuse or melt the wire in the motor. I made the motor with thin guage magnet wire, like what you'd get at Radio Shack. Is this strong enough wire?

- Try it on a much lower voltage first. If it gets hot on a lower voltage that's a pretty good clue that it won't take 120

- Q: What is my problem? Do I have a load that is too large on the motor.Here are the specs:AC 3-PhaseContinuous DutyConstant ToquePower Output: 5 HPBase_RPM: 1750Service Factor: 1.15Power Factor: .75Namplate Current: 14.2 AmpsNameplate Voltage: 230 VWhat I'm doing is increasing the speed of the motor with a VFD. The motor will turn the rotor up to 300 RPM (Well below its base RPM) before it exceeds its nameplate current, which causes the motor to be tripped. Is the motor drawing current above it's rated value to produce more torque to spin the flywheel? The motor can produce 15 ft*lb of constant torque at any speed up to its base rpm, and it is drawing 15.5 Amps at 50 Volts before it trips.

- I assume that when you say that the motor is tripped, you are referring to the electronic overcurrent trip function of the VFD. You can probably increase the trip point to 150% of rated output current unless the VFD is rated only for use with centrifugal pump and fan loads. In that case, it is not expected to be capable of providing rated motor torque below full speed. You need to read and understand the VFD manual. There may be several adjustments and/or a tuning procedure that needs to be performed. It is also possible that the VFD is defective, the motor is defective, or there is a fault in the wiring between the VFD and motor. What is the brand and model of the VFD?

- Q: What advantage does an AC motor have over a DC motor?

- AC induction motor don't require brushes and are extremely rugged. These motors operate at a RPM of 120* Frequency/ pole pairs minus the slip speed. An induction motor with one pole pair will operate just below 3600 RPM ( somewhere around 3400 RPM) at a line frequency of 60 hertz. The slip speed is usually about 150 RPM or so. It varies depended on how heavily loaded the motor is. DC motors require brushes and a commutator or some type of electronic control. This makes these motors more fragile. The speed is variable depending on load which may or may not be useful.

Send your message to us

Worm gear units

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords