Water Pump Series Submersible Sewage Pump From China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Specifications

1)High performance

2)Mechanical seal

3)Cast iron impeller or bronze impeller

4)Lower vibration water pump

5)Large flow

2.Packaging & Delivery

Packaging Detail: | export wooden cases |

Delivery Detail: | within 30 days once receipt of 30% T/T prepayment |

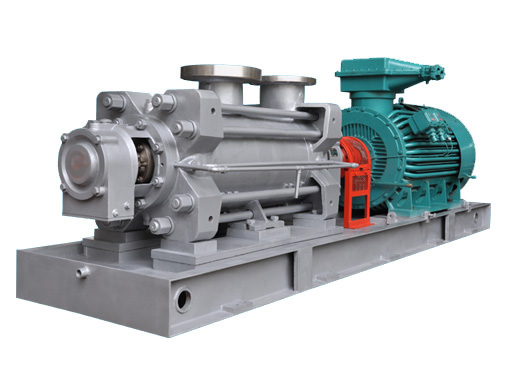

BPO Irrigation Centrifugal Split Water Pump

3.FEATURES

BPO series single-stage double-suction open type centrifugal pump self-researched by the Company after absorbed advanced technology of similar products and combined application requirement of various customers. The series pump adopts excellent hydraulic model, wider type spectrum and better structure. Pump casing is produced by special machine tool, which ensures concentricity among shaft bearing, shaft and pump case, and provides better reliability and maintainability. Apply to municipal water supply and drainage, water circulation of air conditioner, agricultural hydraulic engineering, such as irrigation, drain flooded fields etc., industrial water supply system, firefighting system, water supply and drainage of

heating system, transportation of clean water

4. OPERATING CONDITION

a)Rotate speed: 2950r/min, 1480 r/min, 980 r/min, 730 r/min

b)Flow range: 64.4~9810m3/h

c)Delivery lift: =200m

d)Medium temperature: =80 ,

e)product adopting special materials: -20 ~120

f)Ambient temperature: Lower than 40

g)Operating pressure up to achieves 2.5MPa

5. MATERIAL

a)Pump casing: Cast iron or magnesium iron

b)Pump cover: Cast iron or magnesium iron

c)Impeller: Cast iron, magnesium iron or tin bronze

d)Sealing ring: Cast iron or tin bronze

e)Pump shaft: 45# steel plated with chrome

f)Dynamic and static mechanical sea: Hard carbide, graphite

g)Configuring other material according to requirement is allowable

Rated flow | 10(m3/h) |

Rated head | 26m |

Rated power | 1.5Kw |

Voltage | 220V |

Rated Current | 7.2A |

Rated speed | 2860r/min |

Discharge diameter | 50mm |

6.Conditions of use

Pumps used in the following conditions should be continuously to work properly:

1. For water pumps suitable medium, medium temperature shall not exceed + 40°C

2. The medium PH value between 6.5 ~ 8.5

3. The volume of medium containing solid impurity is less than 0.1%, the size is not more than 0.2 mm

4. The power frequency 50 hz, voltage for single-phase 220 v, 380 v, three-phase voltage fluctuation range for rating of 0.9 to 1.1 times

5. Diving depth of no more than 5 m, is not suitable for irrigation and drainage of sewage and chemicals.

- Q: I want to replace a water pump for my friend. I can't find any books on this car. I'm not sure how to replace this pump. Looking at new water pumps there lookes like 10 bolts, but on my chevy truck there was only 4. I don't know if all holes take a bolt or not, or if I need to take something out before I take the water pump out.Anyone ever changed a water pump on this car? or know what book or website I can look at which will give me an idea.

- I have done many of these water pumps. I would say if you dont know what you are doing, have your friend take it to a reputable repair facility to have the work done properly. The two websites I use you need to subscribe to but they are alldata and mitchell on demand, good luck.

- Q: Hello everyone, is the general household deep well pump capacitor how to pick up ah, 220V voltage, a capacitor, capacitor, there are 2 lines, but the motor is 3 lines, how can I put these 7 lines together?.Please don't copy professional theories from others.

- 220V has two lines (lines 1, lines 2)There are two lines of capacitance (line 3, line 4)There are three lines on the motor (line 5, line 6, line 7)3 11 52 64 7That's plain enough. To change the turn, change any two of the 5, 6, 7, three lines

- Q: Water pump. A drip on the edge of the pump or drip on the ground. Serious concern on which one?

- if its starting to drip coolant from it and it isn't a gasket you need to replace it ,they don't last to long once they start to leak,you can look at it and tell where the leak is coming from,i have seen a few on occasion that was leaking from the gasket where somone had replaced them and not got a good seal back on it,but most of the time your looking at repalcing the water pump,depending on what its on it can be a big job to do,good luck.

- Q: Why my Water Pump is leaking again? It was replace 2 month ago brand new water pump?

- Early WP seal failure, can be due to partially blocked radiator or mixing of antifreeze types occasionally poor quality antifreeze some of the additives become granular and cap bad allowing too much pressure ...early WP bearing failure , fan/clutch assembly out of balance, unit dropped on shaft, hammering on fan clutch to install... In your case I'd guess radiator needs to be cleaned by Rodding it out any radiator shop does it and will verify blockage...have a new inlet tank installed while it's apart...and get cap pressure tested..

- Q: Water pump located on the ground floor of our 10 story building is leaking and therefore it is constantly running and spilling water into the parking lot. Therefore, a plumber shut the water pump off and opened a bypass valve.After we shut off water pump all units still have good water pressure so why do we need to replace water pump?When water pump is on the incoming city water gauge reads 60psi and the gauge measuring the water shooting up into the building reads 80psi. Now both gauges read zero.How can water coming from the city at 60psi travel all the way to the 10th floor without a boost? I do not understand what is happening.

- the pump may have been required before the city up graded their water system. and now it may not be required. but if it were me ? i would replace the pump . Then continue to use the bypass. the reason is , because one day for various reasons the public water pressure could suddenly drop. And then you will and emergency. or at least buy the pump and store it .. So if this ever happens you just need to pay to have it installed. This way you are prepared for what will prob happen someday. but 10 stories ! i am with you . i would think you need a pump to do that.

- Q: i want details and requirement of it in water pump

- A okorder

- Q: I am a business man.My Instituate name is Rockydockyard.This Institiate build up Ships,containerships etc.So we found a high pressure water pump.

- You okorder /... and in collage then you say you have an Instituate or was that Institiate? You probably ought to finish grade school. Then maybe you can find a girlfriend. She may even have a high pressure water pump!

- Q: I have a 2006 Mitsubishi Raider that I'm pretty sure needs a new water pump. It is still under warranty for another 1000 miles, but the nearest dealer is over 200 miles away, and Mitsubishi says they won't reimburse for work done at a non-Mitsubishi Dealer. I'm trying to figure out if the cost of just paying someone to have it done here in town versus having towed 200 miles and then driving it back, plus the lost cost of missed work.By the way my Mitsubishi Roadside Assistance will tow it to the nearest dealer for free, but last time I did that it was barely worth the hassle of dealing with their very poor contract towers.

- Have you asked the dealer to send you the part at least? Call Mitsubishi and ask it that would be possible, you never know. You could send in the old pump and possibly get compensation. Keep your bills. Discuss it with them. Your dealer should provide you with the area Mitsubishi representatives contact information. The prices for those can be expensive. Ask the dealer, service dept, for the labour, how many hrs. to change the pump. They should tell you. Also for the cost of the pump. Add the two together and you have your ans. Join CAA, or AAA, get a gold card, wait two days for the card's towing to take effect, then have it towed in on the card. Done all the time. Or if you have a relative with a Gold card they can have it towed in as long as they are with the car with their card when the tow truck comes.

- Q: My mechanic said I have a very small coolant leak and that in the future I might need to replace it.He said I should keep an eye on my coolant level.Anyone like to comment on how how a quot;small leakmight develop into a quot;major leakthat needs to be urgently addressed?He also said that to replace my water pump, he would charge $400. Is this expensive?(I have a 1996 VW Jetta)

- most water pumps have a small port hole in the pump housing. when your internal seal and/or bearing begins to wear out, you will get a small amount of fluid seeping from this hole. CAUTION, this leak will get much worse, not better. address this problem promptly. the price of repair might be in line depending on parts availability and your location.many mechanics in my area charge up to $40 an hour labor plus materials.

- Q: I have a leak and all the hoses are fine but I am not sure were the water pump is also has anyone had this repaired and what did it cost (part plus labor) in general is it hard to get to? Thanks in advance

- 1995 Chrysler Concorde Parts

Send your message to us

Water Pump Series Submersible Sewage Pump From China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords