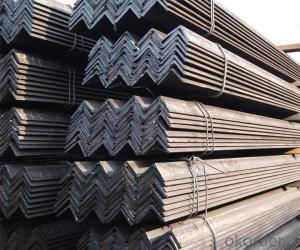

Unequal Leg Angle Steel SS400 Hot-Rolled Mild Steel for Shipbuilding

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Unequal Leg Angle Steel SS400 Hot-Rolled Mild Steel for Shipbuilding at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Unequal Leg Angle Steel SS400 Hot-Rolled Mild Steel for Shipbuilding are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Unequal Leg Angle Steel SS400 Hot-Rolled Mild Steel for Shipbuilding are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Size Leg Length×Leg Length×thickness (mm) | GB Weight (kg/m) | Available Length | Size Leg Length×Leg Length×thickness (mm) | GB Weight (kg/m) | Available Length |

50×32×3 | 1.908 | 6-12m | 100×80×10 | 13.476 | 6-12m |

50×32×4 | 2.494 | 6-12m | 110×70×8 | 10.946 | 6-12m |

56×36×3 | 2.153 | 6-12m | 110×70×10 | 13.476 | 6-12m |

56×36×4 | 2.818 | 6-12m | 125×80×8 | 12.551 | 6-12m |

56×36×5 | 3.466 | 6-12m | 125×80×10 | 15.474 | 6-12m |

63×40×5 | 3.920 | 6-12m | 125×80×12 | 18.330 | 6-12m |

63×40×6 | 4.638 | 6-12m | 140×90×8 | 14.160 | 6-12m |

75×50×5 | 4.808 | 6-12m | 140×90×10 | 17.475 | 6-12m |

75×50×6 | 5.699 | 6-12m | 140×90×12 | 20.724 | 6-12m |

75×50×8 | 7.431 | 6-12m | 160×100×10 | 19.872 | 6-12m |

90×56×6 | 6.717 | 6-12m | 160×100×12 | 23.592 | 6-12m |

90×56×7 | 7.756 | 6-12m | 180×110×10 | 22.273 | 6-12m |

90×56×8 | 8.779 | 6-12m | 180×110×12 | 26.464 | 6-12m |

100×63×6 | 7.550 | 6-12m | 200×125×12 | 29.761 | 6-12m |

100×63×7 | 8.722 | 6-12m | 200×125×14 | 34.436 | 6-12m |

100×63×8 | 9.878 | 6-12m | 200×125×16 | 39.045 | 6-12m |

100×63×10 | 12.142 | 6-12m | 200×125×18 | 43.588 | 6-12m |

100×80×8 | 10.946 | 6-12m |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: How do you straighten a bent steel angle?

- To straighten a bent steel angle, you will need a few tools and equipment. Here's a step-by-step process to help you straighten the bent steel angle effectively: 1. Safety first: Ensure you are wearing appropriate protective gear, including gloves and safety goggles, to protect yourself from any potential hazards. 2. Assess the damage: Examine the bent steel angle to determine the severity of the bend. This will help you decide the best approach to straightening it. 3. Secure the angle: Place the bent steel angle securely in a bench vise or clamp, ensuring that it is firmly held in place. This will prevent any movement during the straightening process. 4. Apply heat (optional): If the bend is severe or the steel angle is hardened, you may need to apply heat to make it more malleable. Use a blowtorch or heat gun to heat the bent area until it becomes red-hot. 5. Use a hammer: With the bent steel angle secured, use a hammer to gently tap the bent area in the opposite direction of the bend. Start from the outer edges and work your way towards the center. Apply gradual force and avoid striking the steel angle with excessive force, as it may cause further damage. 6. Check progress: Periodically release the angle from the vise or clamp to inspect the progress. If necessary, reposition the steel angle to a different area in the vise to continue straightening. 7. Repeat if needed: Depending on the severity of the bend, you may need to repeat steps 4-6 multiple times to achieve the desired straightness. Be patient and take your time to ensure you do not overcorrect or cause any additional damage. 8. Test the angle: Once you believe the steel angle is straightened, carefully remove it from the vise or clamp and test its straightness. Place it on a flat surface and check if it lies completely flat without any visible bends or wobbling. Remember, this process requires precision and caution. If you're unsure or uncomfortable handling this task, it's best to consult a professional or experienced metalworker who can assist you in straightening the bent steel angle safely and effectively.

- Q: What are the limitations of using steel angles in high-temperature applications?

- The susceptibility of steel angles to thermal expansion is one limitation when using them in high-temperature applications. Similar to other materials, steel expands when heated and contracts when cooled. This characteristic can cause dimensional changes in the steel angles, potentially impacting their structural integrity and performance. Another limitation is the potential weakening of steel angles at elevated temperatures. As the temperature rises, the steel can undergo tempering, a process that reduces its hardness and increases its ductility. This can result in reduced load-bearing capacity and increased vulnerability to deformation or failure under high loads or stresses. Furthermore, steel angles are prone to oxidation and corrosion at high temperatures. When exposed to oxygen and moisture in the air, steel can form rust or iron oxide. This can weaken the steel angles and compromise their structural integrity, especially in environments with high humidity or aggressive chemical agents. In addition, steel angles may experience creep when subjected to high temperatures and constant loads. Creep refers to the gradual deformation or elongation of a material under constant stress over time. This can lead to permanent deformation and jeopardize the structural stability of the steel angles. Lastly, the thermal conductivity of steel must be carefully considered in the design and fabrication of steel angles for high-temperature applications. Steel has relatively high thermal conductivity, meaning it can quickly transfer heat. This characteristic can result in uneven heating and cooling of the steel angles, potentially causing stress concentrations or thermal gradients that could impact their performance. Given these limitations, it is crucial to thoroughly assess the suitability of steel angles for high-temperature applications and explore alternative materials or design adjustments to ensure optimal performance and safety.

- Q: How do steel angles perform in extreme weather conditions?

- Steel angles are designed to be highly durable and resistant to extreme weather conditions. They are commonly used in construction and structural applications due to their strength and ability to withstand harsh environments. In extreme weather conditions such as hurricanes, heavy snowfall, or high winds, steel angles provide excellent protection against these elements. One of the key factors that contribute to the performance of steel angles in extreme weather conditions is their high tensile strength. Steel angles can withstand substantial loads and forces without deforming or breaking, making them ideal for withstanding extreme weather events. Additionally, steel angles are known for their excellent resistance to corrosion, which is crucial in areas with high humidity, saltwater, or acidic environments. Steel angles are also highly versatile, allowing them to be easily fabricated and customized to meet specific project requirements. This flexibility ensures that they can be used in a wide range of applications, including buildings, bridges, towers, and other structures that are exposed to extreme weather conditions. Moreover, steel angles can be coated or treated to further enhance their weather resistance. For example, a galvanized coating can provide added protection against rust and corrosion, extending the lifespan of the steel angles even in the harshest weather conditions. In summary, steel angles are designed to perform exceptionally well in extreme weather conditions. Their high tensile strength, corrosion resistance, and versatility make them a reliable choice for structures that need to withstand hurricanes, heavy snowfall, high winds, and other challenging weather events.

- Q: How do steel angles perform in high-temperature environments?

- The inherent properties of steel angles make them highly effective in high-temperature environments. Steel is renowned for its ability to withstand elevated temperatures without significant structural degradation, thanks to its high melting point and thermal conductivity. This means that steel angles maintain their strength and stability, making them suitable for a wide range of applications. A key factor contributing to the exceptional performance of steel angles in high-temperature environments is their structural integrity. Steel has a high melting point, typically between 1300 and 1500 degrees Celsius, depending on the specific grade. This ensures that steel angles retain their shape even in extreme heat conditions, providing durability and reliability. Furthermore, steel's low coefficient of thermal expansion minimizes expansion and contraction when exposed to temperature changes. This is crucial in high-temperature environments as it reduces the risk of warping or distortion of steel angles. The dimensional stability of steel angles enables them to withstand thermal cycling without compromising their structural strength. Moreover, steel exhibits excellent thermal conductivity, enabling efficient heat dissipation. This prevents the accumulation of excessive heat in steel angles, reducing the risk of thermal stress or failure. By effectively transferring heat away from critical components, steel angles increase their durability and longevity in high-temperature environments. Additionally, steel angles can be further enhanced with heat-resistant coatings or treatments. These coatings provide an extra layer of protection against oxidation, corrosion, and thermal degradation, enhancing the resilience of steel angles in extreme heat conditions. To summarize, steel angles are an ideal choice for high-temperature environments due to their high melting point, low thermal expansion, excellent thermal conductivity, and the possibility of additional heat-resistant coatings. Their ability to maintain structural integrity, dimensional stability, and efficient heat dissipation makes them a reliable solution for various applications where exposure to elevated temperatures is a concern.

- Q: What are the different types of steel angles used in bridges?

- A variety of steel angles are commonly utilized in bridge construction for different purposes. These include: 1. Equal Leg Angles: These angles possess equal legs and are frequently employed to provide structural support in bridge construction. They contribute stability and strength to the bridge structure. 2. Unequal Leg Angles: These angles have uneven legs and are used when additional strength or specific load-bearing requirements are necessary. They are often combined with equal leg angles to evenly distribute weight and provide support. 3. L-Shaped Angles: L-shaped angles serve various purposes in bridge construction, such as connecting beams and columns or offering additional support at connection points. They are often used in conjunction with other angle types to create a robust and well-supported bridge structure. 4. Tapered Angles: Tapered angles find application in bridges where a change in width or height is required. They are frequently utilized in bridge piers or abutments to ensure a seamless transition between different sections of the bridge. 5. Bent Angles: Bent angles are used in bridges that require a specific angle to accommodate the design or alignment of the bridge. These angles are often custom-made to suit the specific needs of the bridge construction project. 6. Hollow Structural Section (HSS) Angles: HSS angles are hollow steel sections employed in bridge construction to enhance strength and reduce the overall weight of the structure. They are commonly utilized in situations where weight reduction is a priority, such as in long-span bridges or bridges with high load-bearing requirements. Each of these steel angles serves a distinct purpose in bridge construction, and their selection depends on factors such as design requirements, load-bearing capacity, and structural stability necessary for the bridge.

- Q: Can steel angles be used for framing or supporting partitions?

- Yes, steel angles can be used for framing or supporting partitions. Steel angles are often used in construction for their strength and durability. They can provide structural support and stability to walls and partitions. Steel angles are typically secured to the floor and ceiling and can be used to create a framework for the partition. They can also be used to reinforce existing walls or structures. Additionally, steel angles can be easily cut and welded to fit specific dimensions, making them a versatile choice for framing or supporting partitions.

- Q: Can steel angles be used in window frames?

- Yes, steel angles can be used in window frames. Steel angles are commonly used in construction and can provide structural support and stability to window frames. They are often used as reinforcements or brackets to connect the window frame to the wall or to other components of the window system. Steel angles are durable, strong, and resistant to corrosion, making them a suitable choice for window frame construction. Additionally, steel angles can be easily customized and fabricated to fit different window sizes and designs.

- Q: Can steel angles be used for vehicle frames?

- Certainly, vehicle frames can make use of steel angles. In the construction sector, steel angles are frequently employed due to their structural robustness and adaptability. They possess a diverse array of uses, one of which is constructing vehicle frames. Steel angles offer exceptional support and stability, rendering them well-suited for bearing substantial loads and enduring the various strains and pressures encountered by a vehicle during operation. Furthermore, steel angles can be effortlessly welded or bolted together, allowing for flexibility in the design and construction of vehicle frames. Overall, steel angles present a dependable and long-lasting option for vehicle frames, guaranteeing the vehicle's structural integrity and safety.

- Q: How do you determine the required number of steel angles for a project?

- To determine the required number of steel angles for a project, you would typically need to consider the specific design and structural requirements of the project. This includes factors such as the dimensions and layout of the structure, the load-bearing capacity needed, and any specific codes or regulations that must be followed. A structural engineer or architect would typically perform calculations and analysis to determine the appropriate number of steel angles needed for the project.

- Q: What are the different types of corrosion that can affect steel angles?

- There are several different types of corrosion that can affect steel angles, including general corrosion, pitting corrosion, crevice corrosion, galvanic corrosion, and stress corrosion cracking.

Send your message to us

Unequal Leg Angle Steel SS400 Hot-Rolled Mild Steel for Shipbuilding

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords