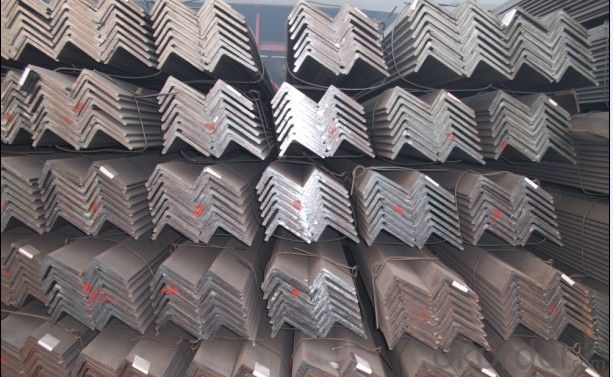

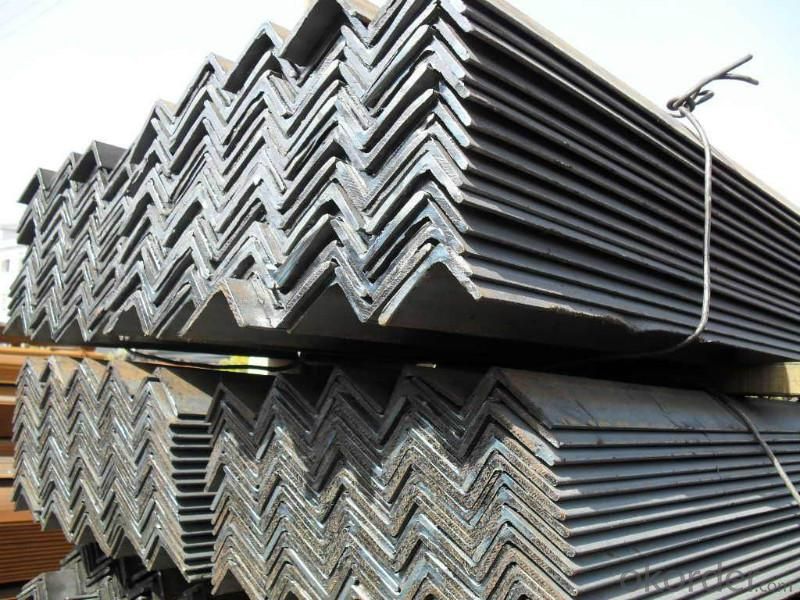

Unequal Steel Angle Mild Hot Rolled Low Carbon Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering Unequal Steel Angle Mild Hot Rolled Low Carbon Steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Unequal Steel Angle Mild Hot Rolled Low Carbon Steel are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Unequal Steel Angle Mild Hot Rolled Low Carbon Steel are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Trademark | Rank | Chemical composition (quality score) % | |||||

C | Si | Mn | S | P | |||

≤ | ≤ | ≤ | |||||

Q235 | A | 0.14-0.22 | 0.30 | 0.30-0.65 | 0.050 | 0.045 | |

Q235 | B | 0.12-0.20 | 0.30 | 0.30-0.70 | 0.045 | 0.045 | |

Trademark | Rank | Pulling Test | |||||

Bend PointΔs/Mpa | Tensile Strength | Elongation Ratioδ5% | |||||

Thickness (Diameter) /MM | Thickness (Diameter) /MM | ||||||

≤16 | 16-40 | ≤16 | 16-40 | ||||

≥ | ≥ | ||||||

Q235 | A | 235 | 225 | 375-500 | 26 | 25 | |

Q235 | B | 235 | 225 | 375-500 | 26 | 25 | |

| UNEQUAL ANGLE STEEL | |||||

| size(mm) | a(mm) | a1(mm) | thickness(mm) | kg/m | length(m) |

| 75*50*5 | 75 | 50 | 5 | 4.808 | 6m,9m,12m |

| 75*50*6 | 75 | 50 | 6 | 5.699 | 6m,9m,12m |

| 75*50*8 | 75 | 50 | 8 | 7.431 | 6m,9m,12m |

| 100*75*7 | 100 | 75 | 7 | 9.34 | 6m,9m,12m |

| 100*75*8 | 100 | 75 | 8 | 10.6 | 6m,9m,12m |

| 100*75*9 | 100 | 75 | 9 | 11.8 | 6m,9m,12m |

| 100*75*10 | 100 | 75 | 10 | 13 | 6m,9m,12m |

| 100*75*12 | 100 | 75 | 12 | 15.4 | 6m,9m,12m |

| 125*75*7 | 125 | 75 | 7 | 10.7 | 6m,9m,12m |

| 125*75*8 | 125 | 75 | 8 | 12.2 | 6m,9m,12m |

| 125*75*9 | 125 | 75 | 9 | 13.6 | 6m,9m,12m |

| 125*75*10 | 125 | 75 | 10 | 15 | 6m,9m,12m |

| 125*75*12 | 125 | 75 | 12 | 17.8 | 6m,9m,12m |

| 150*90*8 | 150 | 90 | 8 | 14.7 | 6m,9m,12m |

| 150*90*9 | 150 | 90 | 9 | 16.4 | 6m,9m,12m |

| 150*90*10 | 150 | 90 | 10 | 18.2 | 6m,9m,12m |

| 150*90*12 | 150 | 90 | 12 | 21.6 | 6m,9m,12m |

| 200*100*10 | 200 | 100 | 10 | 23 | 6m,9m,12m |

| 200*100*12 | 200 | 100 | 12 | 27.62 | 6m,9m,12m |

| 200*100*15 | 200 | 100 | 15 | 34.04 | 6m,9m,12m |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Q4: How many tons of steel products could be loaded in containers?

A4: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Images:

- Q: Can steel angles be used in marine environments?

- Yes, steel angles can be used in marine environments. Steel angles are commonly used in the construction industry due to their strength and versatility. In marine environments, where corrosion and exposure to saltwater can be a concern, it is important to use corrosion-resistant materials. Stainless steel angles or galvanized steel angles are often used in marine applications as they offer excellent resistance to corrosion. These materials have protective coatings or alloys that prevent rusting and degradation, ensuring their durability and longevity in marine environments. Additionally, steel angles can be designed and fabricated to meet specific requirements and regulations for marine structures such as shipbuilding, offshore platforms, and marine piers.

- Q: What is the typical yield strength of steel angles?

- The yield strength of steel angles can differ depending on the grade and composition of the steel. However, for frequently utilized structural steel angles, the yield strength generally ranges from 36,000 to 50,000 psi (pounds per square inch). This yield strength indicates the level of stress or load that the steel angle can endure before experiencing permanent deformation. It is essential to acknowledge that various steel grades and sizes may possess distinct yield strengths, therefore it is advisable to consult the manufacturer or relevant standards for precise and specific information concerning the yield strength of steel angles.

- Q: How can the angle iron tripod be welded or not?

- The angle iron can be made up of different force components according to the different structure, and can also be used as the connecting piece between the components. Widely used in a variety of architectural and engineering structures, such as beams, bridges, towers, hoisting and conveying machinery, ships, industrial furnace, reaction tower, container rack and warehouse shelves.

- Q: Can steel angles be used in conveyor belt supports?

- Indeed, the utilization of steel angles is viable for the support of conveyor belts. Given their robustness and long-lasting qualities, steel angles hold a significant position as structural supports across numerous applications. Their exceptional ability to bear heavy loads renders them suitable for accommodating conveyor belts. By employing steel angles, one can establish a solid framework or structure that ensures the conveyor belt remains stationary while facilitating its smooth movement. Moreover, the convenience of fastening or welding steel angles together ensures a secure and stable support system for conveyor belts.

- Q: Can steel angles be used in curtain wall or facade systems?

- Certainly, curtain wall or facade systems can indeed incorporate steel angles. These versatile structural elements possess the ability to offer support, stability, and aesthetic allure to curtain walls or facades. They can be employed as framing components to construct the structural framework of the system or as brackets to connect different elements. Steel angles possess outstanding strength and durability, enabling them to withstand the various loads and forces exerted upon curtain walls or facades. Moreover, steel angles can be tailor-made in terms of dimensions, shape, and finish to fulfill the precise design specifications of the project.

- Q: What are the common methods of surface preparation for steel angles?

- Steel angles can be prepared for surface treatment through various methods, including grinding, sandblasting, and chemical cleaning. Grinding is a mechanical technique that involves using an abrasive wheel or disc to smooth and level the surface of the steel angle. This method effectively eliminates rust, scale, and other imperfections. It is commonly used for small-scale projects or when achieving a smooth surface finish is not crucial. Sandblasting, also referred to as abrasive blasting, entails propelling small particles onto the surface of the steel angle at high speeds. This method is highly efficient in removing mill scale, rust, paint, and other contaminants. Sandblasting creates a textured surface that enhances the adhesion of coatings or paints. It is often employed in large-scale industrial projects that require a high-quality surface finish. Chemical cleaning involves the use of chemical solutions to eliminate contaminants from the surface of the steel angle. This method effectively removes rust, oil, grease, and other organic materials. Chemical cleaning can be carried out using various techniques, such as immersion or brush application. It is typically employed when sandblasting or grinding is not feasible or practical. Additionally, power tool cleaning, flame cleaning, or a combination of methods may be used for surface preparation, depending on the specific project requirements. It is crucial to select the appropriate method based on the condition of the steel angle, the desired surface finish, and the intended application of the steel angle.

- Q: How do steel angles contribute to the overall earthquake resistance of a structure?

- Steel angles contribute to the overall earthquake resistance of a structure in several ways. First and foremost, steel angles are commonly used as reinforcement elements in the construction industry. When properly installed and anchored, they can help increase the overall strength and stability of a structure, making it more resistant to the lateral forces generated during an earthquake. Steel angles are often used to create moment-resisting frames, which are designed to absorb and distribute the seismic energy throughout the structure. These frames, made up of interconnected steel angles, provide a robust system that can effectively resist the horizontal forces exerted by an earthquake. By distributing the seismic load, steel angles help prevent concentrated stress points and potential failure of the structure. Moreover, steel angles can be strategically placed at key locations, such as corners, junctions, and openings, to enhance the overall stiffness and rigidity of the structure. This increased stiffness helps reduce the building's response to seismic vibrations and prevents excessive deformation, which could lead to structural damage. Additionally, steel angles can be used to create diagonal bracing systems, which are essential for mitigating the effects of seismic forces. These systems consist of interconnected steel angles diagonally placed within the structure, forming a network that improves the building's ability to withstand lateral loads. Diagonal bracing effectively dissipates earthquake energy and redirects it away from critical components, thus enhancing the structure's overall earthquake resistance. In summary, steel angles play a crucial role in enhancing the earthquake resistance of a structure. They provide reinforcement, create moment-resisting frames, increase stiffness, and enable the installation of diagonal bracing systems, all of which contribute to the structural integrity and resilience of a building during seismic events.

- Q: What is the standard size of steel angles?

- The standard size of steel angles can vary depending on the specific application and industry requirements. However, common standard sizes for steel angles typically range from 1/2 inch to 8 inches in width and height, with a thickness that can range from 1/8 inch to 1 inch.

- Q: How do you calculate the slenderness ratio of a steel angle?

- To calculate the slenderness ratio of a steel angle, you need to determine the length and the moment of inertia of the angle section. The slenderness ratio is a measure of how slender or slender a member is, and it helps in determining its stability and ability to resist buckling. First, measure the length of the steel angle, which is the distance between its two ends. This length should be measured in the same unit as the dimensions of the angle section. Next, calculate the moment of inertia of the steel angle section. The moment of inertia is a measure of the section's resistance to bending and is typically denoted by the symbol "I". It depends on the dimensions of the angle section and can be obtained from reference tables or calculated using mathematical formulas. Once you have the length and moment of inertia of the steel angle, you can calculate the slenderness ratio using the formula: Slenderness ratio = (Length of angle) / (√(Moment of inertia)) Make sure the length and moment of inertia are expressed in the same unit before performing the calculation. The resulting slenderness ratio will be a dimensionless value. It is important to note that the slenderness ratio is used to determine the appropriate design criteria and allowable loads for the steel angle. Different design codes or standards may have specific limits or guidelines for the maximum slenderness ratio that can be used safely in different applications. Therefore, it is crucial to consult the relevant design codes or seek professional engineering advice to ensure the correct and safe use of the steel angle.

- Q: What are the safety precautions when working with steel angles?

- When working with steel angles, it is important to follow certain safety precautions to minimize the risk of accidents and injuries. Here are some key safety measures to consider: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE, such as safety glasses, gloves, steel-toed boots, and a hard hat. PPE will protect you from potential hazards like flying debris, sharp edges, and falling objects. 2. Proper Handling: Use mechanical aids, such as cranes or forklifts, to lift and move heavy steel angles. Avoid manual lifting if the weight exceeds your capacity. Ensure the angles are stacked securely and avoid overloading shelves or racks. 3. Work Area Organization: Keep the work area clean and organized to prevent trips, falls, and accidents. Remove any obstructions or clutter that may hinder movement or cause accidents. Clearly mark areas where steel angles are stored or being worked on to prevent unauthorized access. 4. Inspect Tools and Equipment: Regularly inspect and maintain tools and equipment used to work with steel angles. Ensure they are in good working condition, and if any defects are noticed, repair or replace them promptly. Avoid using damaged or faulty equipment. 5. Cutting and Grinding: When cutting or grinding steel angles, always wear appropriate eye and face protection to shield against sparks, dust, and debris. Utilize tools specifically designed for cutting and grinding steel. Ensure proper ventilation in enclosed spaces to minimize the risk of inhaling toxic fumes. 6. Proper Storage: Store steel angles in a designated area where they are not at risk of falling or causing accidents. Use racks or shelves that are suitable for supporting the weight and size of the angles. Securely stack and strap them to prevent them from toppling over. 7. Fire Safety: Steel angles can generate sparks when being cut or welded. Ensure that there are proper fire prevention measures in place, such as fire extinguishers and fire-resistant materials nearby. Keep flammable substances away from the work area. 8. Training and Awareness: Provide appropriate training to all workers involved in handling steel angles. Ensure they have a thorough understanding of the safety precautions, procedures, and emergency protocols. Encourage open communication and the reporting of any safety concerns or incidents. By adhering to these safety precautions, you can minimize the risk of accidents and create a safer working environment when handling steel angles. Always prioritize your safety and the safety of others while working with steel angles.

Send your message to us

Unequal Steel Angle Mild Hot Rolled Low Carbon Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords