Tower Crane Main Section TC5613 Standard

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Detail of Tower Crane

Feature:Tower Crane

Condition:New

Model Number:TC5613(QTZ80)

Place of Origin: China (Mainland)

Brand Name: CMAX

Certification: ISO,CE

Warranty: 1 Year

Application:Building,Construction,Industrial

Main Features of Tower Crane

1) This kind of crane adopts standard section hydraulic lifting and connecting.The max. height can reach 180m with wall tie ins.

2) It has high working speed, good speed-adjusting performance, steady operation and high efficiency. Three-speed motor and mono-speed ratio decelerator are applied in the lifting struction, which enables heavy load low speed and light load high speed.

3)The range-change structure drives the trolley moving on the horizontal crang jib, with good positioning performance. Planet gear decelerator is applied in the circumgyrating structure, together with moment-limiting hydraulic coupler, which can relize high load capacity, steady starting and reliable operation.

4) The crane has complete set of safety devices, which can guarantee the safe and high efficienct operation. The crane is equipped with lifting height limiter, trolley ranging limiter, moment limiter, weight limiter etc..

5)The cranehas scientific layout and handsome appearance. The drivers cab is set independently on one side, with good vision field. It creates a good working environment for the operator.

Specification of Tower Crane

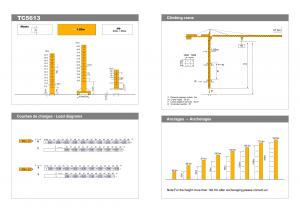

Technical Sheet for TC5613

Free standing height (m) | 46 | ||||

Max height with attachment (m) | 150(200) | ||||

Working range can be adjusted(m) | 44、50、56 | ||||

Min working range(m) | 2.5 | ||||

Max lifting capacity(t) | 8 | ||||

Tip load @ 56m(t) | 1.3 | ||||

Hoist mechanism | Falls | 2 | 4 | ||

Lifting capacity(t) | 0-2 | 0-4 | 0-4 | 0-8 | |

Speed(m/min) | 0-80 | 0-40 | 0-40 | 0-20 | |

Motor | YZRWFc250M-4/8 30/30KW | ||||

Trolleying mechanism | Speed(m/min) | 12/27/53 | |||

Motor | |||||

Slewing mechanism | Speed(r/min) | 0~0.6 | |||

Motor | YZR132M2-6-3.7KW×2 | ||||

Climbing speed(m/min) | 0.5 | ||||

Counterweight(t) | 14.1 | ||||

Mast section size(L×W×H)m | 1.8×1.8×2.5 | ||||

Working temperature | -40-+60℃ | ||||

Total power (KW) | 42 | ||||

Power supply requirement (KVA) | 190KVA for generator | ||||

Cable type ( within 40 meters from site power source to lower electric box of tower crane ) | |||||

Startup voltage & current | 380V×95%=361V 179A | ||||

Rated working voltage & current | 380V 128A | ||||

Loading diagram:

56m jib length:

R | 2.5—13.7 | 14 | 20 | 24.9 | 26 | 32 | 35 | 38 | 44 | 50 | 56 |

a=2 | 4t—24.9m | 3.80 | 2.94 | 2.63 | 2.36 | 1.94 | 1.63 | 1.38 | |||

a=4 | 8t—13.7m | 7.79 | 4.12 | 3.92 | 3.72 | 2.86 | 2.55 | 2.28 | 1.86 | 1.55 | 1.30 |

50m jib length:

R | 2.5—15.1 | 16 | 22 | 26 | 27.6 | 32 | 35 | 38 | 42 | 50 |

a=2 | 4t---27.6m | 3.34 | 2.99 | 2.70 | 2.37 | 1.88 | ||||

a=4 | 8t-15.1m | 7.48 | 5.15 | 4.22 | 3.92 | 3.26 | 2.91 | 2.62 | 2.29 | 1.80 |

44m jib length:

R | 2.5—16.3 | 20.9 | 26 | 29.8 | 32 | 35 | 38 | 40 | 42 | 44 |

a=2 | 4t---29.8m | 3.69 | 3.31 | 2.99 | 2.79 | 2.63 | 2.48 | |||

a=4 | 8t---16.3m | 6.0 | 4.64 | 3.93 | 3.61 | 3.23 | 2.91 | 2.72 | 2.55 | 2.40 |

Images of Tower Crane

FAQ about Tower Crane

Q: What serice you could provide?

A: Providing timely delivery, standby engineers are ready to slove any of your problem

Providing all-embraced warranty of products quality, worksite installation guidance

Providing ample spare parts and training of operation and maintenance

Engineers have more than 20 years' experience in tower crane, ready to solve any of your problems.

Q: What kind of steel used for tower crane ?

A: Normally, as for the main force bearing steel structure, Q345B is adopted; as for the assistance force bearing steel structure Q235B is adopted. All of the raw material is outsourced from qualified steel factory in China.

Q: What about our tower crane warranty?

A: Usually there is one-year quality warranty including main electronic parts (not including consumable parts). There are consumable spare parts together with whole machine and normally they are enough for one year.

Q: What is 3 main mechanism of the tower crane ?

A: there are trolleying mechanism/ slewing mechanism/ hoisting mechanism.

Q: Can you equip with light on tower crane jib, monitor, remote control and anemometer?

A: Sure. All of these could be provided with extra cost upon the clients' requirements. But according to general practice, remote control is not suggested because most of the operator feedback operation in the cabin will provide a wide working view.

- Q: I need step by step information on how to make a paper crane.

- For okorder /

- Q: There is no CAD map attached to embedded parts of tower crane?

- What size do you want?. Each model is different. For example, the 5010 tower bolt embedded needs 24.

- Q: i need a list of materials and a step by step precedure

- I am assuming you mean a low power, miniature crane. You will want to wrap a iron object (a nail should work for light objects) in electrical wiring, the more times the better. Make sure you have a long length of wire after wrapping it around the iron object. Now, attach a rope to the iron object, this will be used to raise and lower it. The length of the rope has to be less than the length of the wires. Now, inside the crane have a battery. The stronger the battery, the stronger the electromagnet. Now, after connecting one of the wires to the battery, connect another one to a switch, then connect then switch with more wiring to the battery. This will turn the crane's claw on and off. The next part is up to you. If you want to be able to raise and lower the magnet, attach the rope to an axel and spin the axel to raise or lower the magnet. If you want to turn the crane, you need to place the arm on a swivel axis. Finally, to bring the magnet closer or farther, you will need a way to raise the arm, bringing the tip of the arm closer to above the center of the crane. I suggest you google some picture of cranes to understand this better.

- Q: Why do tower cranes need to be fabricated?

- The crane wire rope commonly used varieties of phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope, the use of atmospheric environment, patented technology to produce manganese phosphating coating of steel wire rope has the longest lifespan, heavy corrosion environment optimization of hot galvanized wire rope double - phosphating coating.Phosphating coating of steel wire rope production technology patent, give priority to the use of manganese or zinc manganese phosphating, and smooth steel wire rope production process comparison, just add the last bonderizing process, steel wire for rope wear resistance and corrosion resistance is greatly improved, the use of direct phosphating steel wire twisting steel wire rope.

- Q: I have a 2 year old bearded dragon, and there r tons of crane flies flying around everywhere outside. i was wondering if she can eat them in small amounts?

- Hi, yes she can eat crane flies but be aware that this is not good practice due to the possibility that wild crane flies may have come into contact with pesticides and this could be harmful so I would advise not to do it, crickets are cheap enough and your dragons well being is more important than a small financial saving, Stef

- Q: What should i do to solve tower crane collapse?

- tower okorder / to see if whether your trouble is one of those tower crane troubles ?may be you can solve your question under its help.

- Q: Ever felt like a paper crane?

- Made to fly, bended to will, broken in the process because some jerk knocked you down. At the end of the day tossed away because you're nothing more than a delicate pretty thing in their eyes, with a skin as thick as the tissue paper you're made of. Yep.

- Q: We need to purchase spare parts. If there are any supplier in the ASEAN region as possible. We are in urgent need . We are from Viet NamThank you.Email : tuanhuynh62@yahoo,com

- You okorder with contact details. Search for the product you are looking for from the website's search box and you will get the list of suppliers.

- Q: Dear Friends, I wish to design a crane mounted industrial truck of overall weight 2 to 3 tons (including the load). I need a Diesel engine, wheel and brake system, drive system, steering system to desii#92;gn a truck. Please suggest me what all the available cheepest automobile spare parts will suitable for my design and whr can i get these parts easily

- You probably meant a truck-mounted crane. There are industries offering ready-made solutions that work. Have you ever designed a truck or a crane before? It's a challenging engineering task and it can't be improvised. Besides, whatever you design and build will have to undergo extensive testing before being authorized to operate on public roads. The solution would cost more than anyone would care to pay for it. Consider buying a used rig instead.

- Q: I saw da construction of the upcoming tallest building in da world in Dubai,how did da crane get on top of it?

- Why do you write da instead of the? It's irritating. I apologize to you. That was rude and unkind of me.

Send your message to us

Tower Crane Main Section TC5613 Standard

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords