PT5510 tower crane with CE ISO certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Descriptions of our tower crane:

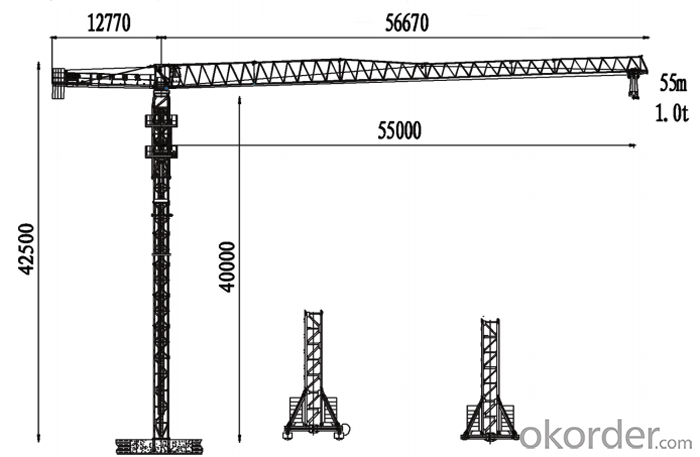

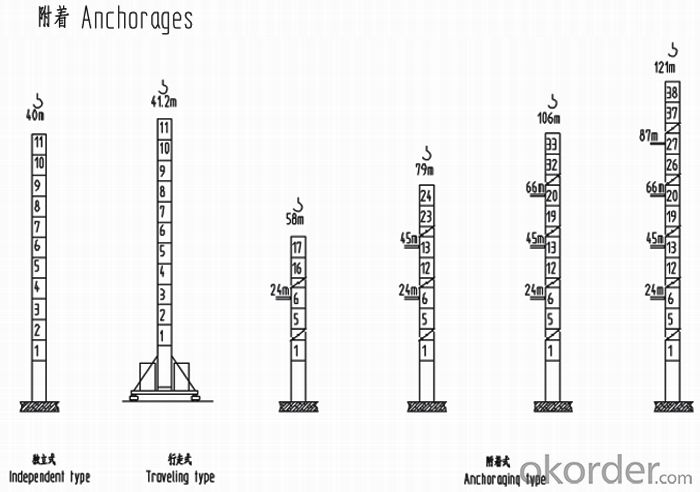

1, PT5510 have competitive price and excellent quality, suitable for all kinds of construction project and can work under all kinds of work condition. With their working radius from 2.5m to 55m, PT5510 tower cranes are famous for their large operating ranges, varied working methods and wide uses.

2,This series of tower cranes has a horizontal jib frame, a jib-trolley radius-changing mechanism and a hydraulic self-raising mechanism.

3, It is original in design, reliable in operation and satisfactory in shape.

4,Equipped with all necessary safety devices, these cranes show a good speed-control capacity,, satisfactory operating stability and high work efficiency.

5,They are widely applied for the construction of high-rise hotels, resident buildings, high-rise industrial buildings, large-span factory buildings and tower like buildings like tall chimneys. Best after sales service will be offered which will get rid of all your worries in the purchase of our products

Advantage of our tower crane:

1, boom relief Angle is big, greatly widened the equipment capacity and scope of work.

2, suitable for the group of tower cross homework.

3, boom stability is good, combination amplitude range.

4, suitable for height have special requirements occasions construction.

5, lifting capacity big, effectively solve the high steel structure construction team crane big lifting capacity requirements.

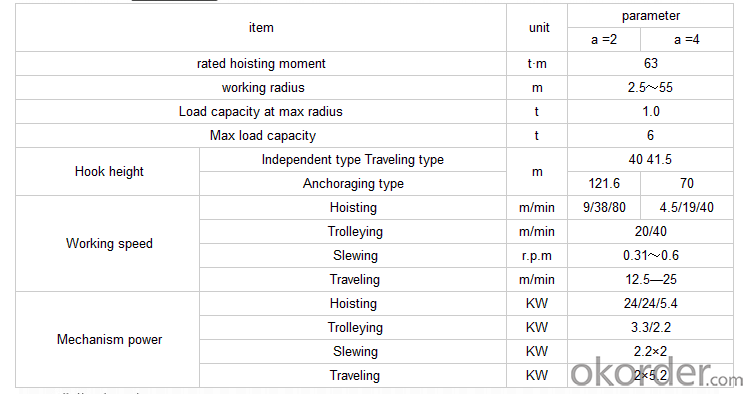

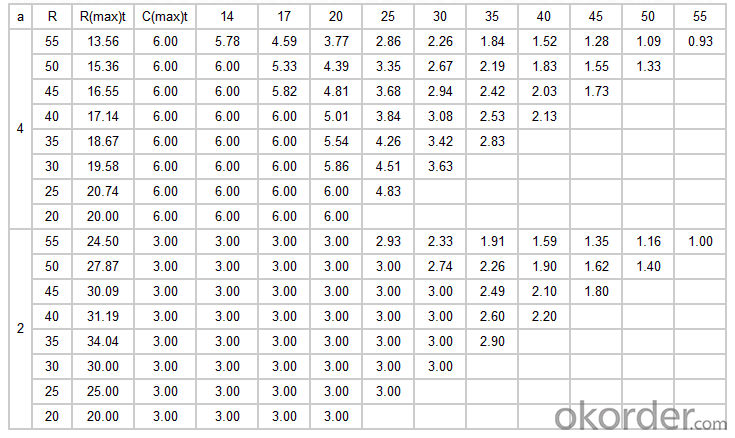

Specification of our tower crane:

- Q: Would you say that Ichabod Crane is socially awkward??

- Slightly, but he's a quirky character. As described in the story, Ichabod Crane is a school teacher who travels to Sleepy Hollow to teach the children of the area. This, in company with his ability to ingratiate himself, persuades many of the townspeople to successively lodge him at their homes for a week at a time, which serves as his sole means of lodging. He follows strict morals in the schoolroom, including the proverbial Spare the rod and spoil the child; outside the schoolroom, he is shown to have few morals and no motive but his own gratification. Despite being thin, he is capable of eating astonishingly large amounts of food and is constantly seeking to do so. In addition to this, he is excessively superstitious, often to the extent of believing every myth, legend, tall tale, etc. to be literally true. As a result, he is perpetually frightened by anything that reminds him of ghosts or demons. If you're talking about the movie Sleepy Hollow, then, Constable Ichabod Crane is a fictional character, played by Johnny Depp. He is a New York policeman with an interest in science, sent to Sleepy Hollow to investigate a string of grisly murders. As in the original story, his horse is named Gunpowder. Ichabod's most notable traits in the movie include an ahead-of-his-time liking for post-mortem examinations and scientific methods, as well as his being very quirky.

- Q: Which kind is better, gantry crane or tower crane?

- Each has advantages, the use of different conditions, the use of different cranes, tower cranes can not move, but the lifting height can be very high, the door machine has tracks can be vertical and horizontal movements, lifting height, tower crane is not high.

- Q: crane:300t lift 100t pad sizes:4.5x2 mtrs.ground bearing capacity required?

- This depends on the angle of the lift and the distance away from centre of the crane. With the lift at tipping range all 400t will be distributed along the outer half of the pad or on the extreme legs. Rule of thumb is all the load is placed under the one pad. so one pad is 9 sq metres and the load is 400 tonnes so the bearing capacity must exceeds 400/9 tonnes per square metre. 44.44444t/m^2

- Q: I just can't figure this out. They need a crane to assemble tall buildings, but how do they assemble the crane? Especially if the building is over 20 stories high. What crane can build a crane higher than itself?

- a mobile crane sets the original lower sections in place, and then the crane is assembled in 6' sections as it climbs itself.

- Q: My hubby just passed his crane test yesterday, and I was wondering how much they pay? He was told to ask for 50k a year..that includes crane time where he works. Can we really ask that? He sets trusses for a big lumber company in Missoula Mt. Any help would be great.

- Huh, I thought crane ops got paid by the tonnage they lift. Maybe there is a base pay in addition to it. But to answer your question, I don't know.

- Q: i am looking for the schematic wiring diagram for GANTRY CRANE AC GENERATOR. thanks a lot

- it sounds like you want to run a gantry crane with a generator the generator should have a wire diagram in side the cover. the gantry crane should have the power requirements on the electric motor there should be a tag on the motor. If you are not sure then you need to get an electrician out there to look at the two components and should be able to get you straight

- Q: What is the insulation resistance of tower crane?

- Two. Safety regulations for tower cranes GB 5144 - 20068.1.3 tower crane metal structure, track, all electrical equipment metal shell, metal line pipe, safety lighting transformer, low voltage side should be reliable grounding, grounding resistance is not more than 4 ohms. Repeated earthing resistance is not greater than l0. The selection and installation of the earthing device shall comply with the relevant requirements of the electrical safety.The insulation resistance of the 8.1.7 main circuit and control circuit shall not be less than 0.5M ohm.

- Q: why are siberian cranes endangered?

- Wetland loss means Siberian Crane loses ground Siberian Crane Grus leucogeranus is now listed as Critically Endangered, having previously been listed as Endangered in 1994. Its population is estimated to be 2,500-3,000 and comprises three separate populations. The western population breeds in western Siberia and winters in Iran, and the central population breeds in western Siberia and winters in India. Both the western and central populations are on the verge of extinction as a result of habitat loss and hunting. The much larger eastern population breeds in eastern Siberia and winters in the lower Yangtze basin in south-east China. The main threats to this population are wetland destruction and degradation at staging areas and wintering sites caused by agricultural development and the development of oil fields. The main wintering site in China, Poyang Lake in Jiangxi Province, holds 95% of the global population but is potentially threatened by future hydrological changes resulting from the construction of the Three Gorges Dam and other dams. If the operation of these dams prevents the development of suitable winter feeding conditions for waterbirds at Poyang Lake and other wetlands, Siberian Crane and other threatened species could undergo extremely rapid population declines in the near future.

- Q: Is the pink paper crane used to represent Lulu?

- i really dont know what i can say to that so ill just shut up

- Q: i'm doing it for fun but i was wondering because my aunt had a baby that like 1 and the baby has cancer and i'm gonna try this to help her please don't be mean like the only thing you will get is sore hands and stuff is it true or is it a myth only answer if you did thid and i want to know what happened to you but anyway ill pray to god that everything will be ok with the baby

- Although I hope the baby is ok, this is not going to help anything. Folding 1000 cranes will just waste paper and your time. Instead just keep the baby in your prayers and hope God will handle the rest. God bless and I'll keep your aunt and her baby in my prayers

Send your message to us

PT5510 tower crane with CE ISO certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords