Golden Color T-Bar Drywall Ceiling Grids

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Flat Suspension Grids) Description

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

2,Main Features of the (Flat Suspension Grids)

Shape:Plane,groove

Groove T bar ceiling grid (FUT) & FUT Ceiling Grid system is made of high quality prepainted galvanized steel,which guarantee the characters of moisture proof,corrosion resistanct and color lasting.The automatic cold roll forming and punching machineries guarantee the high precision.

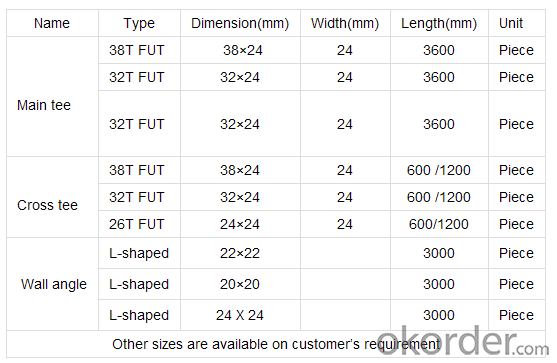

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

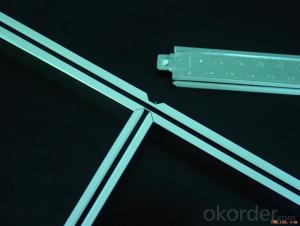

3,(Flat Suspension Grids) Images

4,(Flat Suspension Grids) Specification

5,FAQ of (Flat Suspension Grids)

1. Convenience in installation, it shortens working time and labor fees.

2. Neither air nor environment pollution while installing. With good effect for space dividing and beautifying.

3. Using fire proof material to assure living safety.

4. Can be installed according to practical demands.

5. The physical coefficient of all kinds Suspension

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

- Q: Light steel keel gypsum board ceiling, hanging bar, the main keel, sub keel, cross-keel spacing is how much

- The distance between the main keel is generally between 80 and 120 cm, depending on the use of thick gypsum board, if the gypsum board thick, or double gypsum board, the main keel spacing is small, and vice versa can be appropriate Enlarge the number, but not more than 1.2 meters; hanging bar spacing, is the same, according to the size of the main keel to determine the distance between hanging bars and hanging bars, but the same can not exceed 1.2 meters; sub keel (50 keel ) Spacing, the general use of 9.5mm gypsum board when it is 30 cm, if the thickness of the gypsum board is 12mm, the distance between the vice keel can be enlarged to 40 cm. But here we are basically using 30 cm spacing of.

- Q: each point on the grid. The weight of each 4x4 area is 144# ( square footage is 9# PSF ) which I divide into four seperate areas and come up with a reaction so I know what spring to use at each point. The basic areas are easy to calculate because it's either rectangular or square but some areas are cut up, for example there are areas shaped like an L on the grid with two rectangular sides and I don't know how to get their reaction because there are more than four points. Could someone show me a formula for this?

- Sounds like you will probably need to break up the oddly shaped areas, and consider them as a collection of rectangles. However, my understanding is still a little fuzzy. What's this reaction stuff? I don't have a clear picture of the layout in my head.

- Q: Gypsum board light steel keel cut off how much money 1 square

- Skeleton 20 or so, gypsum board 12 thick side of the double-sided dragon card 30 or so, labor costs ranging from OKorder and around 35, caulking and 5, nail river 2, tools and 3 fast, 90 or so, plus noise Material plus artificial 20 or so, 110

- Q: Our bedroom has 4 recessed lights in the ceiling that form the perimeter of a 6x6 square. I would like to install a ceiling fan in the middle but it would require me to install a new wiring box. Is it possible to tap into the wiring my recessed lights run off of to run my ceiling fan? Or do i need to run all new wiring to my panel? Thanks in advance for your experiences and help.

- No , you cannot do that , you will be arrested and put in jail if anyone ever finds out what you have done.

- Q: T-type light steel keel TB24 * 38 What does it mean?

- T-type is not on the person, the width of 24mm, height 38mm is the T-type main keel

- Q: It is done before the floor tiles, or in the shop after the tiles to do it?

- Light steel keel partition in the shop before, after all is possible, paving the brick can be done in the tiles above, to the keel with the glue and tiles can be a solid paste the normal construction.

- Q: Light steel keel and aluminum alloy keel the difference is the difference between material or specifications? I mean! What are their materials! I am a beginner, not clear!

- Material and specifications are different, light steel keel is generally used to ceiling and partition, aluminum keel is also used to ceiling, mainly for mineral wool board, embossed gypsum board and other ceiling

- Q: I'm doing a reno in my basement and want to put crown molding up but can't imagine it looking good. Any suggestions?

- It would look absurd on a drop ceiling (metal grid and removable tiles). You wouldn't use any molding at all on such a ceiling.

- Q: there will not be anything stored above this ceiling. insulation will be used between the beams plus electrical fictures.

- 24 feet is a large span ...im a builder in uk ...you never gave the other dimension ..if its smaller ..that's the way to go ...however if we used a steel beam for that span it would need to be at least 12deep by 6wide ..a lot for a non loadbearing situation ...the joist would be 7x2 at 16centres....on any steel you will need padstones where they sit ..either concrete or blue brick

- Q: Do not know who can tell me ah

- Set the hanging bar on the beam 1) Hanging rods should be straight and have sufficient carrying capacity. When the embedded bar need to take a long time, must be lap welding, Welds should be evenly full. 2) the length of the boom from the main keel shall not exceed 300mm, otherwise the boom should be increased. 3) ceiling lamps, tuyere and maintenance mouth should be set up additional boom.

Send your message to us

Golden Color T-Bar Drywall Ceiling Grids

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords