PVC Coated Galvanized Steel Ceiling Grid T Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

Ceiling T-grid is rolled into moulds by galvanized steel coil and color-coated steel coil. It can be made into several specifications according to different kinds of ceiling. Owing to be beautiful, high-strength, anticorrosive and waterproof, Ceiling T-grid can suspend mineral fiber ceiling boards and pvc laminated gypsum boards in offices, shops and other places.

Its nature of fire-resistance is far more superior to the traditional interior decoration materials of wood and it is available for various kinds of ceiling panel in installation, like miner fiber board, gypsum board, PVC gypsum board and metal ceiling panel.

Raw Materials:

High-quality hot -dipped galvanized steel coil.

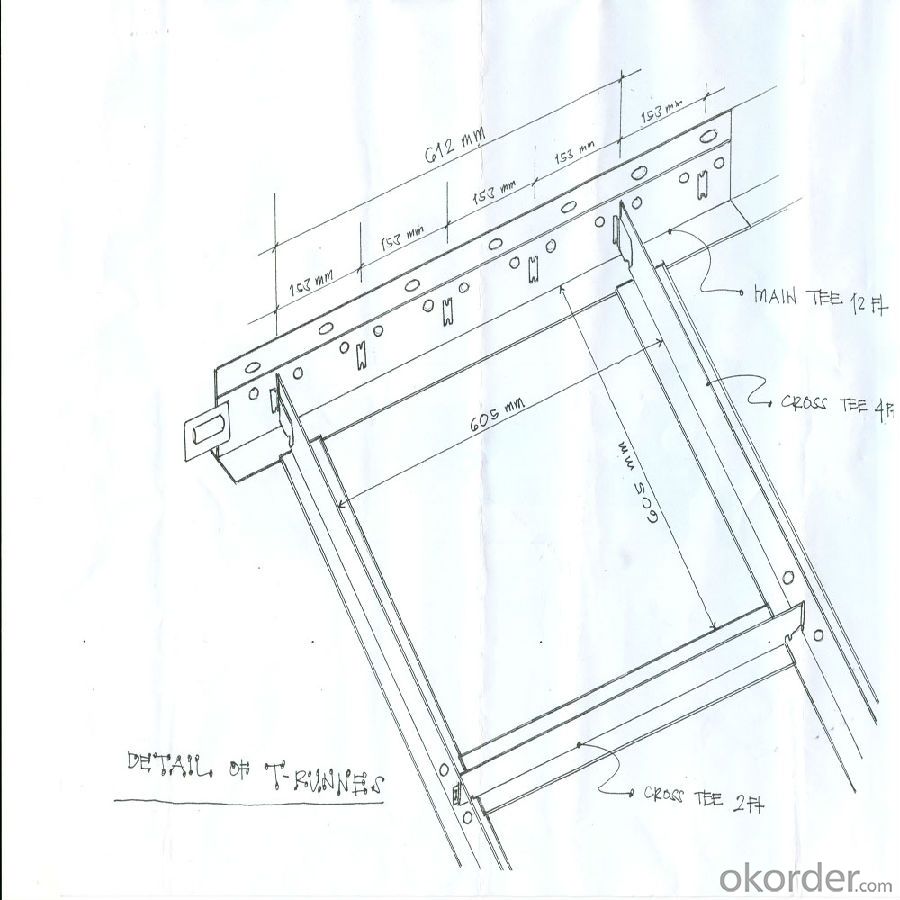

Install Methods:

Galvanized steel ceiling grid ceiling t bar

Size

Specification:

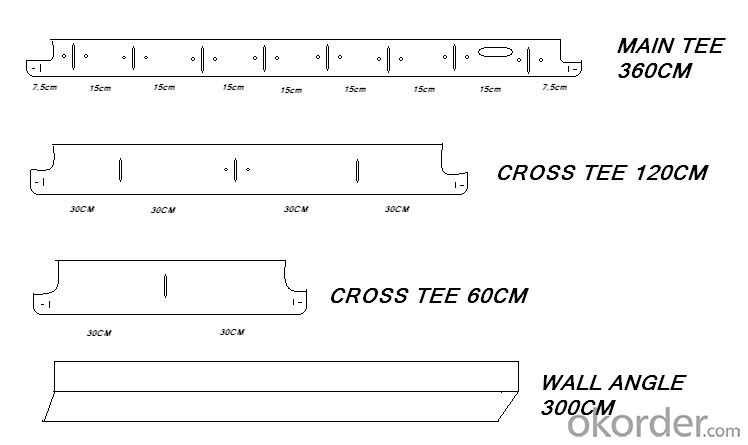

Normal Plane T-Grid / T-Bar System (NPT system )

Main Tee

Size: (Height×width×Length)

38×24×3600/3660/3750mm

32×24×3600/3660/3750mm

Thickness:0.26mm,0.30mm,

0.35mm,0.40mm

Cross Tee

size: (Height×width×Length)

26×24×1200/1220/1250mm

26×24×600/610/625mm

Thickness:0.26mm,0.3mm

Wall Angle

Size: (Height×width×Length)

24×24×3000mm

20×20×3000mm

Thickness:0.3mm,0.4mm

Narrow(Slim) Plane T-Grid / T-Bar System (SPT system )

Main Tee

Size: (Height×width×Length)

30×24×3600/3660/3750mm

Thickness:0.26mm,0.3mm

Cross Tee

Size: (Height×width×Length)

30×24×1200/1220/1250mm

30×24×600/610/625mm

Thickness:0.26mm,0.3mm

Wall Angle

Size: (Height×width×Length)

20×14×3000mm

20×14.5×3000mm

24×24×3000mm

Thickness:0.3mm,0.4mm

Products Photos:

Maim Tee Cross Teec Wall Angle

Packaging: Packed in Carton, Carton in Container

Shipping: All the shipping ways can be choosed, check as below.

FAQ:

1.When can we get the price?

We usually quote within 24 hours after getting your detailed requirements,like size,quantity etc. .

If it is an urgent order, you can call us directly.

2. Do you provide samples?

Yes, samples are available for you to check our quality.

Samples delivery time will be about 3-10 days.

3.What about the lead time for mass product?

The lead time is based on the quantity,about 2-4 weeks.

4.What is your terms of delivery?

We accept FOB, CFR, CIF, EXW, etc. You can choose the most convenient way for you. Besides that,

we can also shipping by Air and Express.

5.Product packaging?

We are packed in wooden cases, or according to your requirements.

Galvanized steel ceiling grid ceiling t bar

- Q: looking to hang suspending ceiling tiles but what should i charge for a square footage?

- Are you looking to install suspended ceiling? It depends on the tile and grid and your location. Complete ceilings in the Bay Area of California go for about $1.20 to 2.00 per square foot. I have never heard of anyone just installing the tile.

- Q: I would rather not drywall the ceiling to provide future access to wiring and ductwork. What could be used to reduce overall noise? I am most concerned about the master bedroom, which is right above the area being finished, as there will be a home theatre system installed.

- Definately go with a suspended acoustical ceiling. It muffles noise, is easy to install, and you can set fluorescent light fixtures into the grid. The article Install a Suspended Grid Ceiling on the following link, tells you just how to do it, step by step.

- Q: Home decoration with wood keel good or light steel keel good

- Specifically to see what kind of top hanging, if it is pvc wood keel of course, if it is gypsum board, of course, light steel keel. Integrated ceiling.

- Q: 120mm light steel keel wall keel model is how much

- Sound insulation cotton is not necessary, but the best place, brick wall at least 100, the other commonly used there are 200,240 specifications.

- Q: I am finishing my basement and want to install a drop/suspended ceiling instead of drywalling it. I want the ceiling to be as high as possible but have a bunch of large ducts in the middle of the room. Do I just build a bulk head around the duct work and then put tiles around it or are there a bar system that will do that for me? I just don't want my whole ceiling at the height of the duct work.

- First okorder /?XlinkID=13 Typical drop ceilings need about 4 whereas the CeilingMax mounts flush. As for the ducts, you could box them out with plywood and just paint them with a semi-gloss white paint (or the same as your trim color). I personally wouldn't tile them. If they are square and tight to the ceiling, you could install the CeilingMax right up to the side of the duct and just paint the duct itself.

- Q: For one of my classes I have to do a floor plan with furnishings and electrical and then I also have to do a reflected ceiling plan of the same floor that includes lighting, HVAC, and finished materials. I was just wondering what the difference is?

- Reflected Floor Plan

- Q: What are the meanings of the letters in the CB, DB CS, DF DM of the light steel keel? Seeking different people to explain ah

- CS: C-type superior keel, should refer to the ceiling 60 bearing keel: 60 * 27 * 1.2, DF: ceiling cover keel or ceiling vice keel or ceiling to pay keel anyway are covered keel, DM is the main keel (main) The ceiling carries the keel

- Q: While I won't get into the reasons why, I ended up drywalling my walls in a small sitting room in my basement before doing the ceiling. The walls have since been painted. What are my options for installing drywall in the ceiling and what types of roadblocks may I encounter when doing so?

- How To Drywall Ceiling

- Q: the kind meant for office and school ceilings that fit in a ceiling grid(4, t8 tubes), i was thinking of using 4, 8 inch jack chains and securing it with s hooks and eye hooks. is this alright or will i have to find another way? I'm using #10 eye hooks and 1 s hooks.

- Yes, you can suspend them with jack chain and eye hooks. I installed literally thousands of those lights (we called them troffers when I was a commercial electrician. In fact, in most cases even if we were dropping them in the grid for main support we also had to suspend two or four ceiling tie wires or jack chain supports to each fixture for earthquake security.

- Q: How does the aluminum-plastic plate and the light steel keel connect?

- Wood keel and aluminum-plastic plate for the cross-shaped arrangement, aluminum-plastic plate with self-tapping screws in the aluminum-plastic plate splicing from the bottom up on the keel. The next board up a fixed board on a plug, you can block the tapping screws, then the board is not fixed on the same side with a self-tapping screw twisted on the keel. And so on. The first board, and the last side of the board has a special edge of the edge, the edge of the first with a keel or glue fixed on the wall, then insert the board. So easy to disassemble and strong. Keel playing level, the board will be able to level.

Send your message to us

PVC Coated Galvanized Steel Ceiling Grid T Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords