Wood Ceiling Grid Suspension System Frame for Ceiling Tiles - Ceiling Tee Bar

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

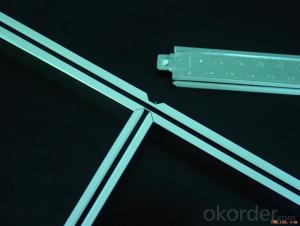

Suspension System Frame for Ceiling Tiles-Ceiling Tee Bar

Specification of Suspended Ceiling Grid :

1.There are Flat system, Groove system and Slim system for t grid

2.Four kind of tee make up of a ceiling frame. those are main tee, long cross tee, short cross tee and wall angle

The height normally is 38 or 32, thickness from 0.20-0.40MM

The normal size as belows(pls mainly focus on the lenghth we have):

main tee:38*24*3600mm or 38*24*3660mm

main tee:32*24*3600mm or 32*24*3660mm

long cross tee:26*24*1200mm or 26*24*1210mm

Short cross tee:26*24*600mm or 26*24*610mm

wall angle:24*24*3000mm or 24*24*3050mm

wall angle:21*21*3000mm or 21*21*3050mm

Applications of Suspension Ceiling Grid:

commercial ceiling suspension grid for false ceiling

Package of Suspension Ceiling Grid

1.main tee:30 pcs in one carton

2.long cross tee: 50 pcs in one carton

3.short cross tee:75 pcs in one carton

4.wall angle:50 pcs in one carton

Production Line of suspension ceiling grid

We have 6 production line for ceiling grid, 30 containers per month. our quality undertested by the world market over many years we are your unique relible choice

- Q: Ok, I need to know if they either prevent conduction, convection or radiation . I also need to know how they prevent these thermal energy transfer mechanisms (conduction,radiation and convection) from occuring.

- Tall trees: If you have tall trees around your house, your house will be cooler because of the shade. The trees are blocking radiation from the sun, and to a lesser extent stopping convection to the air around the house by acting as a wind block. The air around your house removes heat through open, free convection. Polystyrene: The polystyrene panel itself has less conduction than other materials because it is less dense. Conduction is essentially shaking the atoms of the materials. Less dense things typically have less atoms to shake. (There are exceptions). But if you are talking about a dropped ceiling (with the panels haning from the real ceiling in the metal grid) as a whole system, there is more to it than that. Without the panels, you would lose heat to your roof (and the world outside) by convecting from your room to the ceiling, CONDUCTING through the ceiling, and convecting to the world outside. Your sandwich would be: Outside world Ceiling Room air But a dropped ceiling adds some more layers in there, most importantly a space of dead air, which is an excellent insulator - similar to a thermapane window. Your sandwich would become: Outside world Ceiling Dead (not moving) air between polystyrene panels Polystyrene panels Room air The extra layer in the sandwich helps. Polystyrene makes a good insulator, but it would still work if you dropped a ceiling with metal panels because of the dead air. In heat and mass transfer problems, it is critical that when you ask the question, you define what the system boundary is. My answer is long because I don't know what that is in your question. Hope it helps.

- Q: the ceiling tile with no keels.(there are keels inside it but you can't see them cuz they're hidden),so how do you call this kind of ceilig tile?

- Sorry Yangyang, but I don't understand the meaning of keels in the ceiling tiles. There is a style of ceiling called a dropped ceiling where a metal grid framework (often white) hangs lower than the original ceiling and square, often white tiles are placed inside the grid. If any wires or repairs need to be done above the dropped ceiling they can just push up on a tile, do the repairs and then drop the tile back into place. It is seen often in office or industrial spaces and occasionally in residential. It is fairly modern. An older style of ceiling treatment know as a tin ceiling tiles are an antique metal patterned and textured tile that are attached directly onto the ceiling. They are found in old and often expensive homes and sometimes restaurants. Although they are an antique (starting in the 1800s) you can still buy plastic or metal ones to add to a home giving it an old style charm. Are either of these what you are looking for?

- Q: Light steel keel ceiling in the card type of the main keel what model

- Card keel is divided into: 23 25 28 32 38 These specifications, the height is generally increased with the model and increased

- Q: Is installing a suspended ceiling difficult?

- Well, that depends. Is the power already there and good to go? If you want to install a ceiling fan where a light is currently hanging, there could be problems also. However, assembling and hanging a ceiling fan is easy. E-mail me w/ more details and I can help you. I have installed 100's of fans, literally!!

- Q: Is it good to use a light steel keel?

- Now the light steel keel are generally treated by the paint, moisture-proof waterproof performance trustworthy, but the weight of the point, a long time will sag. Wood keel light, easy to install and the price is relatively low, but there are some children defect.

- Q: What is ceiling called that has big moldings across it?

- If the big moldings are in a grid pattern on the ceiling, it is called coffered.

- Q: I am finishing my basement and want to install a drop/suspended ceiling instead of drywalling it. I want the ceiling to be as high as possible but have a bunch of large ducts in the middle of the room. Do I just build a bulk head around the duct work and then put tiles around it or are there a bar system that will do that for me? I just don't want my whole ceiling at the height of the duct work.

- First okorder /?XlinkID=13 Typical drop ceilings need about 4 whereas the CeilingMax mounts flush. As for the ducts, you could box them out with plywood and just paint them with a semi-gloss white paint (or the same as your trim color). I personally wouldn't tile them. If they are square and tight to the ceiling, you could install the CeilingMax right up to the side of the duct and just paint the duct itself.

- Q: How many millimeters are the main keel spacing during the construction of the lightweight steel keel ceiling?

- Fixed hanging rod Fix the hanging rod with expansion bolts. Not on the ceiling, boom length less than 1000mm, you can use φ6 hanging Rod, if more than 1000mm, should be used φ8 boom, should also set the reverse support. The boom can be cold drawn And disk round bar, but the use of disk round steel should be used to straighten the machine. Master's ceiling, boom length less than 1000mm, You can use φ8 of the boom, if more than 1000mm, should be used in the user φ10 boom, should also set the reverse support. One end of the boom is welded with L30 × 30 × 3 angle code (the aperture of the corner code should be determined according to the diameter of the boom and expansion bolt) The other end can be tapped out with more than lOOmm screw, you can also buy finished screw welding. Make a good boom should do Rust treatment, boom with expansion bolts fixed to the floor, with the impact hammer drilling, aperture should be slightly larger than the expansion of the bolt diameter.

- Q: Can the interior walls be made of light steel keel partitions? Bathroom wall and interior wall with light steel keel wall is good or brick wall good?

- The interior walls can be made of light steel keel partitions, but the bathroom walls should be made of brick walls.

- Q: Do not know who can tell me ah

- Fixed hanging rod Fix the hanging rod with expansion bolts. Not on the ceiling, boom length less than 1000mm, you can use φ6 hanging Rod, if more than 1000mm, should be used φ8 boom, should also set the reverse support. The boom can be cold drawn And disk round bar, but the use of disk round steel should be used to straighten the machine. Master's ceiling, boom length less than 1000mm, You can use φ8 of the boom, if more than 1000mm, should be used in the user φ10 boom, should also set the reverse support. One end of the boom is welded with L30 × 30 × 3 angle code (the aperture of the corner code should be determined according to the diameter of the boom and expansion bolt) The other end can be tapped out with more than lOOmm screw, you can also buy finished screw welding. Make a good boom should do Rust treatment, boom with expansion bolts fixed to the floor, with the impact hammer drilling, aperture should be slightly larger than the expansion of the bolt diameter.

Send your message to us

Wood Ceiling Grid Suspension System Frame for Ceiling Tiles - Ceiling Tee Bar

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords