Tee Grid for Ceiling Tiles Tee Grid for Ceiling Tiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceiling channel and drywall channel, made of high-quality Snowflakes Steel

Product Applications:

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance

2.Matching magnesium fire-proof board,gypsum board and many other wall and ceiling board

3.Moisure-proof ,shock-resistant,high-effcient and environmentally-friendly

4.Easy and fast for installation,time-saving

5. Prompt delivery, high quality ,competitive price and complete sets of styles

6.We can supply you the products based on your specific requirements

Main Product Features:

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health and not pollute the environment.

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a selective way, in order to strength the

keels' vertical points and intensity.

(4) Various sizes of metal track and metal stud : we are able to manufacture German, Japan and Aus-American types etc..

We can meet your customized demands.

Product Specifications:

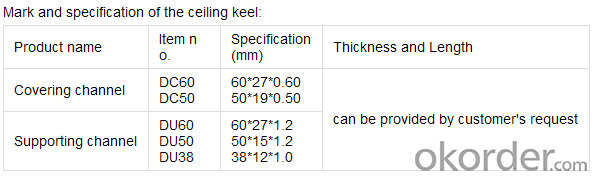

Image

- Q: Light steel keel gypsum board ceiling or aluminum-plastic plate ceiling good?

- Which depends on where to use, the public places office aluminum-plastic plate is good, good family gypsum board, aluminum plate high cost.

- Q: How much is the base price?

- Light steel keel gypsum board partition should be set 2004 decoration quota. 1, quotation number 3-45; 2, the amount of engineering assumptions 1 square meters; 3, the unit square meter; 4, the project name assembled U-shaped light steel ceiling keel (not on the type) surface specifications 600mm * 600mm plane; 5, base price of 31.95 yuan (of which: labor costs 7.6 yuan material costs 24.2 yuan mechanical costs 0.07 yuan); 6, because the price is 1 square meters and the same as the unit price; 7, where the material needs to be converted in the original quota 600 * 600 panel material, each square meter needs 1.015 square meters, the content of the price of 20 yuan, to convert into the current price, is the price of gypsum board, the other unchanged, so the project quota Finished over.

- Q: Home decoration with wood keel good or light steel keel good

- Specifically to see what kind of top hanging, if it is pvc wood keel of course, if it is gypsum board, of course, light steel keel. Integrated ceiling.

- Q: I want the finished look to be like a grid pattern just on the wall my bed is on. The part that confuses me is how to attach the molding to the wall? Do I need to install MDF or something similar before laying out my grid pattern?

- You shouldn't have to install MDF in order to do that unless maybe your wall was not flat. And yes, it should look good with a vaulted ceiling. You'll also want to make sure that your trim boards aren't bowed. Most likely, all you'll really need to do is nail where the studs are on your wall.

- Q: I have a little package to do their own works, only the contractor does not material, people give the price is 13 dollars a square, but also put noise cotton, in general, that the calculation area is to be considered double or single of,

- I also do decoration, in general, the calculation area is single-sided, the paint is double-sided operator, this is not absolute, the key is how the contract on the set! 13 of the price is too low, the project is rarely the case of 20 to a flat (artificial)!

- Q: Light steel keel hanging flat how to calculate the material?

- Material usage Gypsum board 1.05 square meters Main keel 1.22m Vice keel (including crossed keel) 4.45m Side keel 0.44m Keel pieces of 3.05 Deputy keel connection 0.83 Main keel connection 0.43 25mm tapping screw 29 Pendant 8.8 Cracked paste 0.50kg Seam tape with 1.50m

- Q: I'm getting a new room in my house, and I really want to do a mosaic on the ceiling. I love everything artistic so I'd want to do it myself, and I know it's going to take a long time to do a room that's 18 ft by 22 ft, but I really want to. I've actually never done mosaics before and I'm aware that they are difficult to do and that this is a monumental project for someone who has never even done a mosaic before. But I wanted to know the easiest possible way to go about it (because the idea of standing on a ladder the entire time does not appeal to me whatsoever)? Like, could I do the mosaic on another surface and then attach it to my ceiling? or I don't know, please help me.

- Monumental doesn't even came close. To make it realistic you will need to do it on the ceiling, otherwise it will look like patchwork. First thing is to design on paper what you want it to look like. Then transfer design to grid paper. No stepladder. Buy a scaffold that is big enough and high enough to lie on. Transfer your design to the ceiling. You can make stencils for this, and use multiple chalk lines to keep everything straight. Before you start, practice on a plywood board. When you buy your materials, make sure you tell the salesman you are doing a ceiling so you get the right cement or mastic. It took Michelangelo 7 years to do the Sistine Chapel, and he used paint. Good Luck!

- Q: anyone know how to put up something called ceiling max its like a drop ceiling that is a inch from ceiling?

- Great Link MM, but I don't see anything in the text that suggests the FREE space above all the grid work and tiles. Beyond that the text deals with a basement, and/or an area of exposed rafters. Normal drop ceiling requires a drop in the area of 8 inches minimum. I'd be doing Ceiling Max to cover damaged ceilings if I could get to within and inch or 2 of the old. The process, as explained is no different than normal grid install for a drop ceiling. I'll do more research however. The Q nudged an issue I have in a home, and I do drop ceilings with my Son often, commercially.

- Q: I'm putting suspended ceiling in my basement (using Armstrong tiles). Unfortunately, on one of the walls, the level of the ceiling has to be above the top level of the wall framing (it's a long story involving a structural beam, some heating vents and a window), so there are no studs behind the drywall where I need to attach the wall molding. Would molly bolts or something like that be able to support the weight of the suspended ceiling, should I try to cut some wood to fit and block in behind the drywall, or is there something else that I should do?

- A coarse thread drywall screw would work, but then you would have to counter-sink each screw and go back and putty over each screw before you paint your molding or it would look horrible. Rent an air compressor and a finish nailler. It will shoot the finish nails into the metal studs. (just make sure that you use 16 gauge not 18... they would just bend ). It will make the job quick and easy too. It will be well worth the cost of renting if you don't want to buy one.

- Q: I would like to hang curtains from the ceiling to function like a room divider. But I can't make any holes in the ceiling, so does anyone know how I could do this? Or any alternatives to using some fabric as a room dividerThanks in advanced

- you just go to legacydecors dot com and i think you can find best and stylish room dividers for your room decoration plz visit once if you want to buy quality and stylish room dividers

Send your message to us

Tee Grid for Ceiling Tiles Tee Grid for Ceiling Tiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords