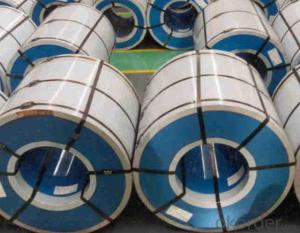

supply High Quality Prepainted steel coil/EM/color coated steel coil/PPGI/PPGL

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,GB,JIS | Grade: | SGCC/DX51D | Thickness: | 0.17-1.6mm |

| Place of Origin: | HEB,hebei, china China (Mainland) | Brand Name: | CNBM | Model Number: | WL-100 |

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Application: | building material, roofing, household appliance, etc. | Special Use: | High-strength Steel Plate | Width: | 58-1250mm |

| Length: | 339-5243M | Color: | red green blue white brick red 3005 6005 8017 5005 9006 9003 RAL Color | WL01: | PPGI 150-3 |

| Factory: | Bazhou shengfang winroad building materials co.,ltd |

Packaging & Delivery

| Packaging Detail: | Standard export and seaworthy packing. i.e. waterproof paper and metal sheet protection with fluted rings at inner and outer edges, 4 eye bands and 4 circumferential bands fasten the coil(or according to customer's requests),.. |

| Delivery Detail: | 30 days after receiving prepayment or original L/C. |

Specifications

supply High Quality Prepainted steel coil/EM/color coated steel coil/PPGI/PPGL

Grade:SGCC,DX51D,CGCC

Thick:0.17-0.8

High Quality Prepainted steel coil

color color prepainted galvalnized steel coils

Mill of Pre Painted color coated steel plate/sheet(thick:0.17-1.2mm)

Brief Introduction

1. Color steel is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

2. The base metals for Color steel consist of cold rolled, HDG electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of Color steels can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the Color steel has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The Color steels can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

6.We are supplying Secondry quality/Over Rolled/Galvanized/Prepainted/Steel sheet & Coils with thickness Of 0.25 mm to 0.50 mm, width 950 and above.

We are also supplying cr base color coils/embossed coils with thickness 0.35 mm to 0.50mm. Contact me please, then when i have the list, i will send you ASAP.

Certificate: ISO 9001/14001

The main specification is as belows:

Standards: GB/T12754, JIS3312 , EN 10169 ASTM A755

Thickness: 0.14-0.8mm; Width: 914-1250mm

Tolerance : +2/0mm,thickness tolerance :+0.02/-0.02mm (or according to customers' request).

Coating mass: Top;13-25, Back: 5-10

Coil weight: 5-8 metric tons

Coil DM: I.D: Φ508m/610mm O.D: Max Φ1500mm

Coating type: PE, SMP, HDP, PVDF

Common performance of front coating:

(1). Thickness: ≥20μm

(2). Pencil Hardness: 2H

(3). 60° specular glossiness of coating: >60

(4). 180°bend: ≤3T

(5). Impact: ≥9J

(6). Salt Fog Resistant: ≥500h

(7). Color difference: <3ΔE

Application

1. Construction: (Outside) workshop, agricultural warehouse, residential precast unit, corrugated roof, wall, rainwater drainage pipe, terrace, retailer booth, roller shutter door

(Inside) door, doorcase, light steel roof structure, folding screen, ceiling, elevator, stairway, vent gutter

2. Electrical appliance: refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker

3. Furniture: central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf

4. Carrying trade: exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board

5. Others: writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment

NAME

| PPGI | GALVANIZED

| GALVALUME/ALUZINC

|

CERTIFICATE | ISO9001 | ||

STANDARD

| GB/T-12754 JIS G 3312 EN 10169 ASTM A755 | GB/T-2518 JIS G 3302 EN 10142/10427 ASTM A653 | GB/T-14798 JIS G 3321 EN 10215 ASTM A792 |

GRADE

| SGCC DX51D SGCH CGCD1-CGCD3 CGC340-CGC570 GRADE

| SS GRADE33-80 SGCC SGCH SGCD1-SGCD3 SGC340-SGC570 SGCC DX51D | GRADE33-80 SGLCC SGLCD SGLCDD SGLC400-SGLC570 SZACC SZACH SZAC340R |

MODEL NO | 0.16MM-1.0MM*1250MM OR UNDER | (0.12-1.5)*1250MM OR UNDER | 0.16MM-1.5MM*1250MM OR UNDER |

TYPE

| Steel coil Steel sheets/plates Corrugated steel sheets/plates

| Steel coil Steel sheets/plates Corrugated steel sheets/plates | Steel coil Steel sheets/plates Corrugated steel sheets/plates

|

TECHNIQUE | Hot rolled-cold rolled -galvalume /galvanized -PPGI/PPGL | Hot rolled-cold rolled - galvanized | Hot rolled-cold rolled -galvalume /Aluzinc

|

SURFACE TREATMENT | Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating,color | Mini/regular/big/zero spangle, Chromate treatment /chromate-free treatment /untreated unoile/oiled, TENSION LEVELLERT SKIN PASS anti-fingerprint/un-anti-fingerprint, Coating

| |

APPLICATION | Structural use ,roofing, corrugated roofing, commercial use, household appliance, industry, family | ||

SPECIAL APPLICATION | Wear resistant steel, high- strength - steel plate | ||

- Q: How do steel coils contribute to seismic resistance in structures?

- Steel coils contribute to seismic resistance in structures by providing strength and flexibility. The coiled shape allows the steel to absorb and dissipate the energy generated during seismic events, thereby reducing the impact on the structure. This increased flexibility helps prevent the structure from collapsing under the stress of seismic forces, making it more resistant to earthquakes.

- Q: How are steel coils processed at the steel service centers?

- Steel coils are processed at steel service centers through a series of steps. First, the coils are unrolled and flattened using a decoiler and a leveling machine. Then, the steel is cut into the desired length and width using shears or slitting machines. Next, the coils may undergo various treatments such as pickling, galvanizing, or coating to enhance their corrosion resistance or appearance. Finally, the processed coils are inspected, packaged, and prepared for shipment to various industries for further manufacturing or construction purposes.

- Q: Classify the following in as many ways as possible:stainless steelpureheterogeneous mixturehomogeneous mixturenone of these

- Stainless steel is an iron-carbon alloy that contains about 13% chromium. There are 3 types, each of which have different properties depending on what ingredient is added and these are...nickel, carbon, and manganese... Stainless steal is homogeneous in that you only see one phase (steel) and none of the different parts from which it is made...

- Q: What are the different methods of welding steel coils?

- There are several different methods of welding steel coils, each with its own advantages and applications. The most common methods used in welding steel coils include: 1. Resistance Welding: This method uses pressure and electric current to generate heat and join the steel coils together. It is commonly used for high-speed production and can be further categorized into spot welding, seam welding, and projection welding. 2. Arc Welding: This method involves creating an electric arc between an electrode and the steel coils, which generates intense heat and melts the metal. There are various types of arc welding techniques, such as shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW). 3. Laser Welding: Laser welding utilizes a highly focused laser beam to melt and join the steel coils together. This method offers precise control, high welding speeds, and minimal heat-affected zones, making it suitable for thin materials and intricate designs. 4. Electron Beam Welding: This technique employs a concentrated beam of high-velocity electrons to melt and fuse the steel coils. It is commonly used for welding stainless steel and other high-temperature alloys, as it provides deep penetration and minimal distortion. 5. Friction Stir Welding: In this method, a rotating tool with a pin is plunged into the steel coils, creating heat through friction. The softened material is then stirred together to form a solid joint. It is commonly used for joining aluminum, but can also be applied to steel coils. 6. Ultrasonic Welding: Ultrasonic welding involves applying high-frequency vibrations to the steel coils, which creates friction and generates heat to fuse the materials together. This method is commonly used for smaller steel coils and can provide fast and efficient welding with minimal distortion. These are some of the different methods of welding steel coils, each offering unique advantages and suitable for specific applications. The choice of welding method depends on factors such as the type and thickness of the steel, desired strength and quality of the weld, production speed, and cost considerations.

- Q: How are steel coils used in the manufacturing of medical equipment?

- Steel coils are commonly used in the manufacturing of medical equipment as they serve as a crucial component in various applications. These coils are often employed in the construction of medical devices such as surgical instruments, orthopedic implants, and diagnostic equipment. The high strength and durability of steel make it ideal for these purposes, ensuring the longevity and reliability of the medical equipment. Additionally, steel coils are used in the production of medical furniture, such as hospital beds and examination tables, providing stability and support. Overall, steel coils play an essential role in the manufacturing of medical equipment, contributing to the quality and functionality of these devices.

- Q: I would like to buy a new cold steel recon 1 folding knife. My concern is the knife is made in Taiwan, will the quality of blade/overall make is lower quality compare with those made in US/JAPAN? The plan is use as an EDC, any good suggestion with similar style? Most important to me is reliability, 2)sharpness, 3) maintance than 4)cost. Anyone can point me into right direction? Please share, Thanks in advance.

- Cold okorder /

- Q: What are the different types of steel coil storage locations?

- There are various types of steel coil storage locations, including open yards, covered warehouses, coil racks, and specialized coil storage systems.

- Q: The length of a steel beam increases by 0.78 mm when its temperature is raised from 22 degrees C to 35 degrees C. What is the length of the beam at 22 degrees C (in meters)?I used: L = (0.78 mm)/[(9/5)(.00000645 F)(13)] = 5.17 meters but Mastering Physics said Not quite. Check through your calculations; you may have made a rounding error or used the wrong number of significant figures. I'm confused because this is how we learned this kind of problem in class, so if anybody knows what I did wrong, feel free to correct my errors! Thanks

- It seems you are trying to convert celsius to Fahrenheit, Why? There is no need. Delta L= alpha (initial length) (delta celcius) what you need is an alpha, it should be given in degrees celsius to the negative first (steel's alpha happens to be 0.000036 1/celsius). You also need the length of the beam at 35 degrees C. This answer (delta L) needs to be added (if heat is rising) or subtracted (if heat is dropping) to the original length.

- Q: How are steel coils processed for galvanizing or coating?

- Steel coils are processed for galvanizing or coating through a series of steps. First, the coils are cleaned to remove any dirt or oil. Then, they go through a chemical treatment to prepare the surface for coating. After that, the coils are coated with a layer of zinc or another protective material. Finally, the coated coils are cured or heated to ensure proper bonding and adhesion of the coating.

- Q: I personally don't believe the story of 8 guys who flew small planes can navigate passenger jets into buildings hundreds of miles away with that precision. It just doesn't make sense.I am wondering what the story surrounding the molten steel was, how could molten steel have been produced when fuel from the planes wasn't hot enough (it melts at 2850 degrees)?

- that's just it: there wasn't very much molten steel for the very reason you point out. Jet fuel burns at 800° to 1500°F. This is not hot enough to melt structural steel. However, engineers say that for the World Trade Center towers to collapse, their steel frames didn't need to melt, they just had to lose some of their structural strength. Steel will lose about half its strength at 1,200 degrees F. The steel will also become distorted when heat is not a uniform temperature. after the collapse, a LOT of folks took a look at the remains. the result was the conclusion that the fire caused the central core of the building to weaken. When the floors collapsed one on top of the other, the weight was too much for the weaked core to bear, causing the result we are all familiar with. hope this helps

Send your message to us

supply High Quality Prepainted steel coil/EM/color coated steel coil/PPGI/PPGL

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords